Preparation method of alpha-aluminum oxide with narrow original grain size distribution

A technology of alumina and grain size, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve the problems of wide original grain size distribution, unstable particle size distribution, and poor re-sintering activity. , to achieve the effect of narrow original grain size distribution, perfect grain development and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

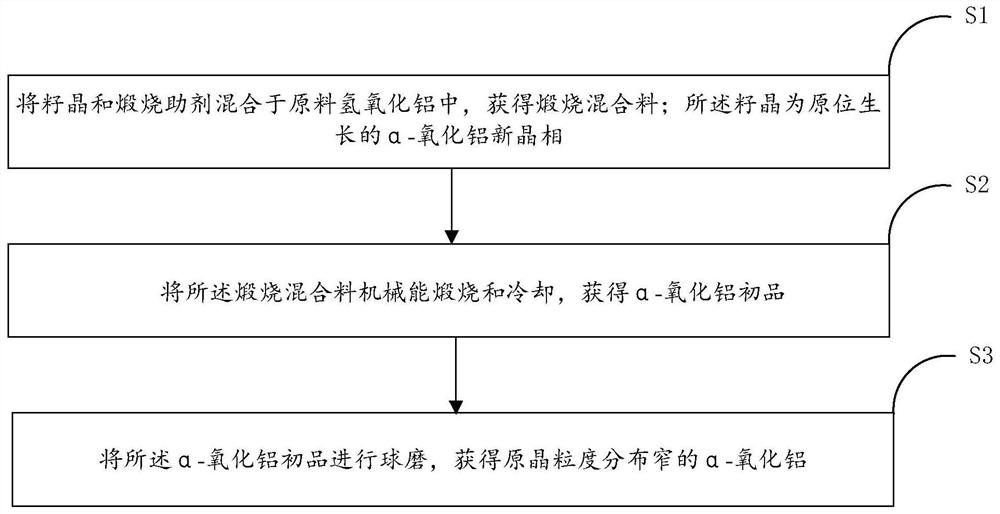

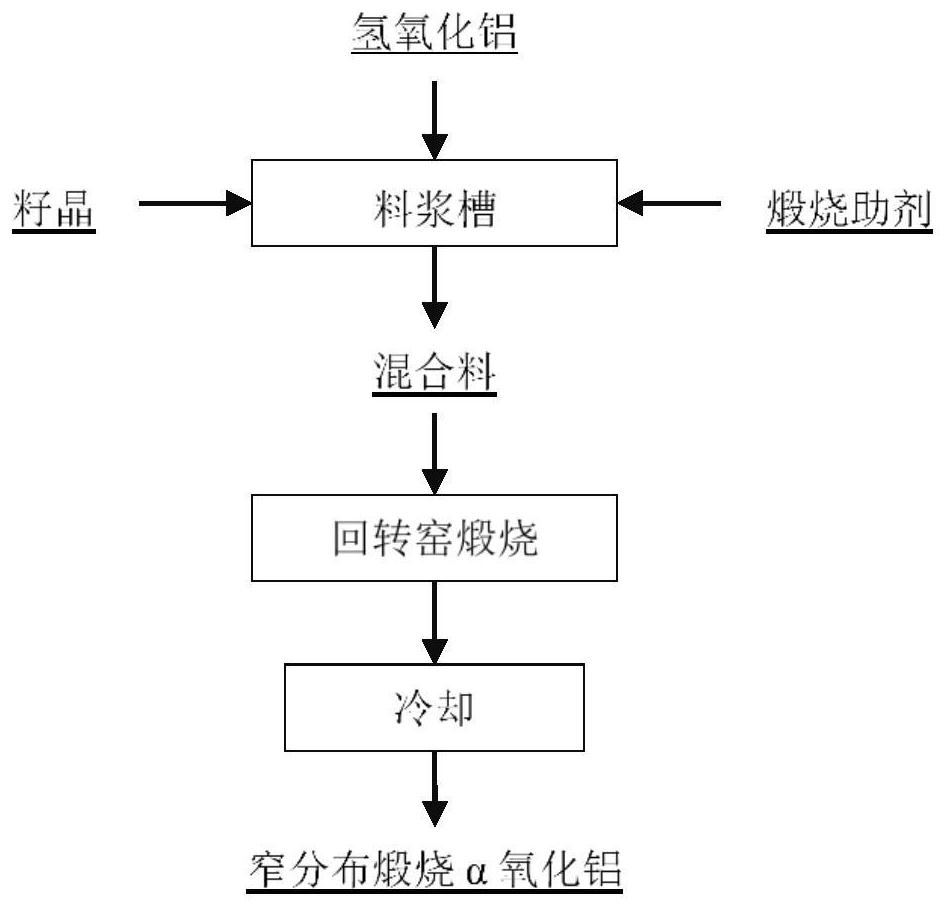

[0030] According to a typical embodiment of the present invention, a method for preparing α-alumina with a narrow primary grain size distribution is provided, the method comprising:

[0031] S1. Mixing the seed crystal and the calcining aid in the raw material aluminum hydroxide to obtain a calcined mixture; the seed crystal is a new crystal phase of α-alumina grown in situ.

[0032] As an optional embodiment, the seed crystal and the calcination aid are mixed in the raw material aluminum hydroxide to obtain the calcined mixture. In terms of weight fraction, the amount of the seed crystal added is 0.1% of the aluminum hydroxide. %-20%.

[0033] The reason for controlling the addition of seed crystals to 0.1%-20% of the aluminum hydroxide is to induce seed crystals, reduce the phase transition temperature of α-alumina, reduce powder agglomeration, control grain size, and enhance powder regeneration. Sintering activity, increase specific surface area, reduce internal defects of...

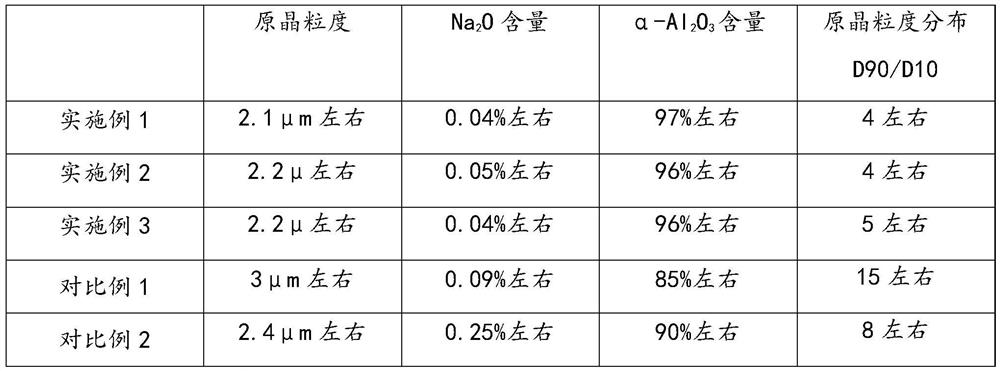

Embodiment 1

[0047] A method for preparing α-alumina with a narrow primary grain size distribution, the method comprising:

[0048] S1. Using aluminum hydroxide A as raw material, Na 2 O content is 0.35-0.5%;

[0049] S2. Add 0.05% aluminum fluoride (addition accounted for alumina weight %), add in solid form; Add 5% seed crystal α-Al 2 o 3 (the amount added accounts for the weight percent of alumina) S3. uniformly mix the seed crystal with aluminum hydroxide and aluminum fluoride to obtain a mixture, and calcinate it at a temperature of 1450° C. for 30 minutes in a rotary kiln;

[0050] S4. Calcining, cooling and lowering the temperature, and ball milling to a certain particle size, the calcined α-alumina with a narrow particle size distribution of the primary crystal can be obtained.

Embodiment 2

[0052] A method for preparing α-alumina with a narrow primary grain size distribution, the method comprising:

[0053] S1. Using aluminum hydroxide A as raw material, Na 2 O content is 0.35-0.5%;

[0054] S2. Add 0.05% aluminum fluoride (addition accounts for alumina weight %), add in solid form; Add 8% seed crystal α-Al 2 o 3 (addition accounts for alumina weight %)

[0055] S3. uniformly mixing the seed crystal with aluminum hydroxide and aluminum fluoride to obtain a mixture, and calcining at a temperature of 1450° C. for 30 minutes in a rotary kiln;

[0056] S4. Calcining, cooling and lowering the temperature, and ball milling to a certain particle size, the calcined α-alumina with a narrow particle size distribution of the primary crystal can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com