Barium titanate-based PTC thermal sensitive ceramic powder and preparation method and application thereof

A heat-sensitive ceramic and barium titanate-based technology, which is applied to subcutaneous injection devices and other directions, can solve the problems of large particle size of barium titanate-based PTC thermistor ceramic powder, uneven mixing of components, and high sintering temperature. Improved safety and temperature stability, narrow grain size distribution, and high sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

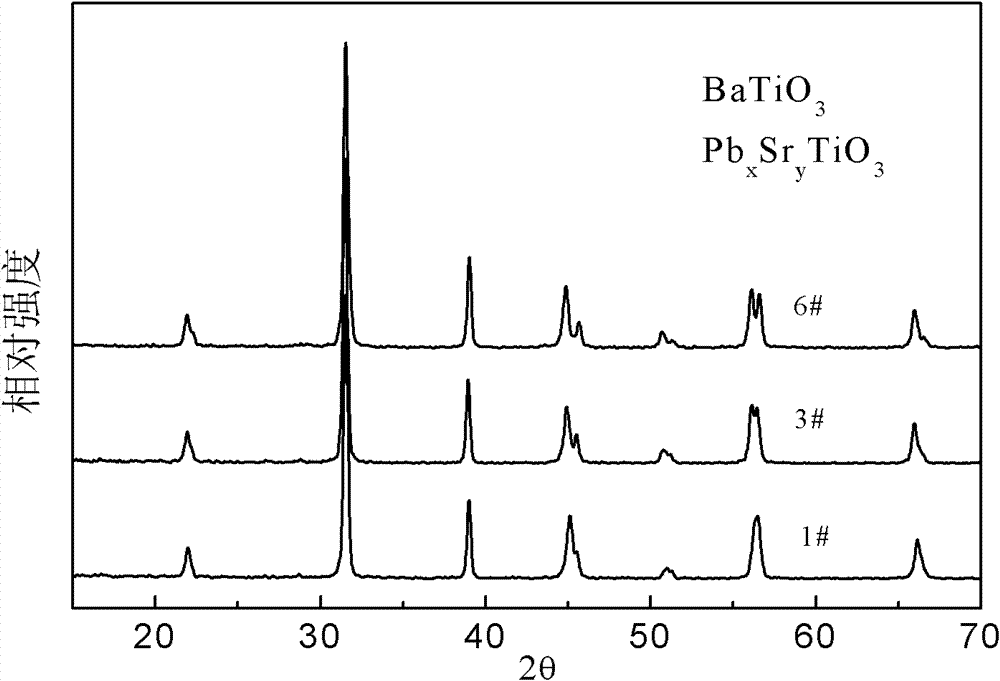

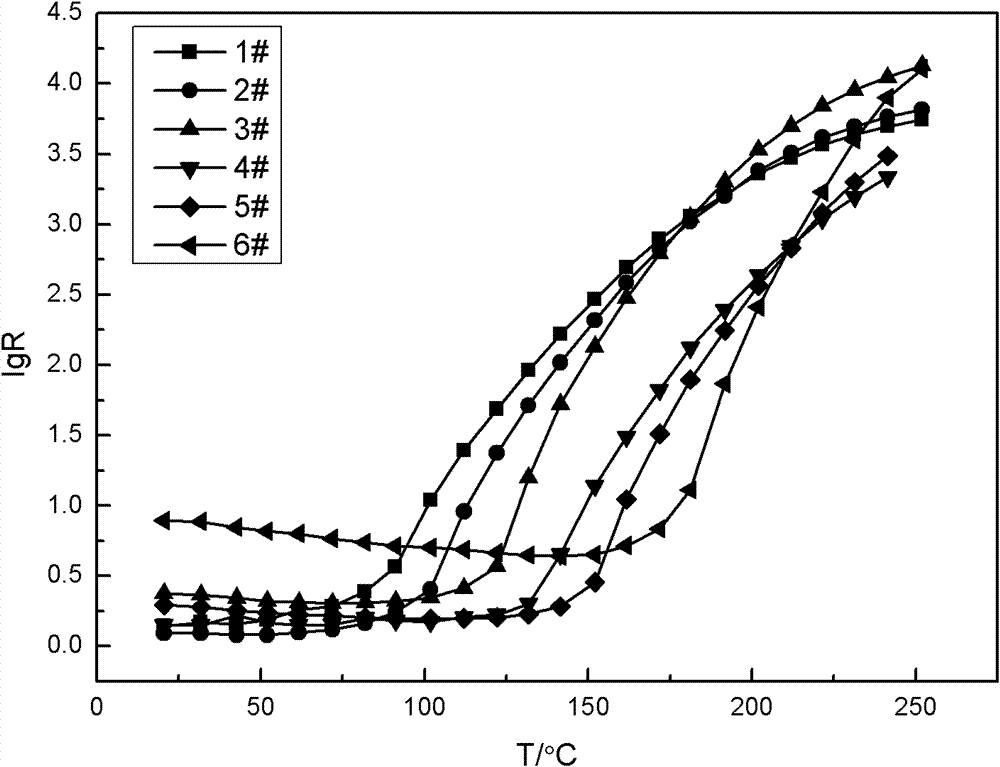

[0031] The chemical composition of the preparation is: Ba 1-x-y-0.12 Pb x Sr y Ca 0.12 TiO 3 0.001YO 3 / 2 0.00015MnO 2 0.15SiO2 2 Ceramic powder, fixed content of Ca, Mn, Y, Ti, Si, x and y are 0, 0.13 (1 # sample); 0, 0.08 (2 # sample); 0, 0.03 (3 # samples); 0.03, 0(4 # sample); 0.08, 0(5 # sample); 0.13, 0(6 # Sample).

[0032] The following assumes that x is 0 and y is 0.13 (1 # sample) as an example, using the sol-gel method to synthesize barium titanate-based PTC ceramic nanopowder, the specific steps are as follows:

[0033] (1) Weigh 69.2234 g of tetrabutyl titanate according to the stoichiometric ratio, add 60 ml of glacial acetic acid and 20 mL of ethanol solution of 0.1499 mol / L ethyl silicate, and stir thoroughly;

[0034] (2) Weigh 5.5024g of strontium nitrate and 38.3607g of barium acetate according to the stoichiometric ratio, add 24mL of 1.001mol / L calcium acetate solution, 2.4mL of 0.01305mol / L manganese nitrate solution, 4mL of 0.0500mol / L yttriu...

Embodiment 2

[0042] According to the method described in Example 1, a ceramic powder with the following composition was prepared:

[0043] Ba 0.64 Pb 0.12 Sr 0.12 Ca 0.12 TiO 3 0.005YO 3 / 2 0.00035MnO 2 0.15SiO2 2

[0044] Ba 0.57 Pb 0.18 Sr 0.10 Ca 0.15 TiO 3 0.006YO 3 / 2 0.00025MnO 2 0.13SiO 2

Embodiment 3

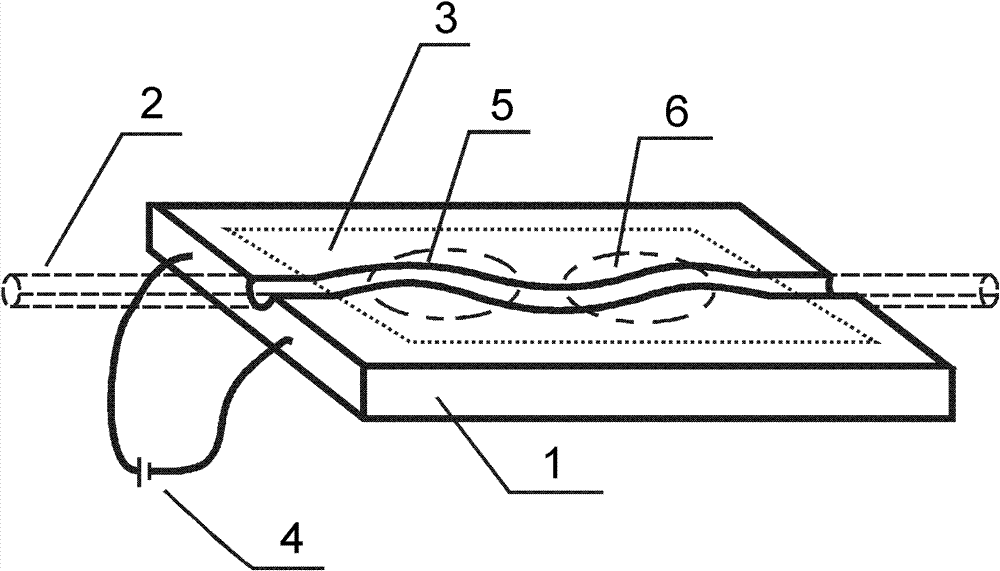

[0045] Embodiment 3 Utilize the PTC thermistor prepared in Embodiment 1 as the infusion thermostat designed for the heating plate

[0046] image 3 It is a schematic diagram of the infusion thermostat. In the figure, it includes (1) thermostat substrate, (2) infusion tube, (3) insulation material coated on the substrate, (4) DC regulated power supply, (5) low Curie temperature heating sheet, (6) High Curie temperature heating element.

[0047] Using the resistance-temperature characteristics of barium titanate-based PTC ceramics, that is, the resistivity is low below the Curie temperature, and the resistivity rises sharply near the Curie temperature, the high Curie temperature (such as 180 ° C) and the low Curie temperature (such as 80°C) the heating plates are connected in parallel, the heating plate with higher Curie temperature is in front, and the heating plate with low Curie temperature is behind. When heating, the infusion tube first flows through the heating plate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com