Nano barium titanate microcrystal and preparation method thereof, and barium titanate powder and preparation method thereof

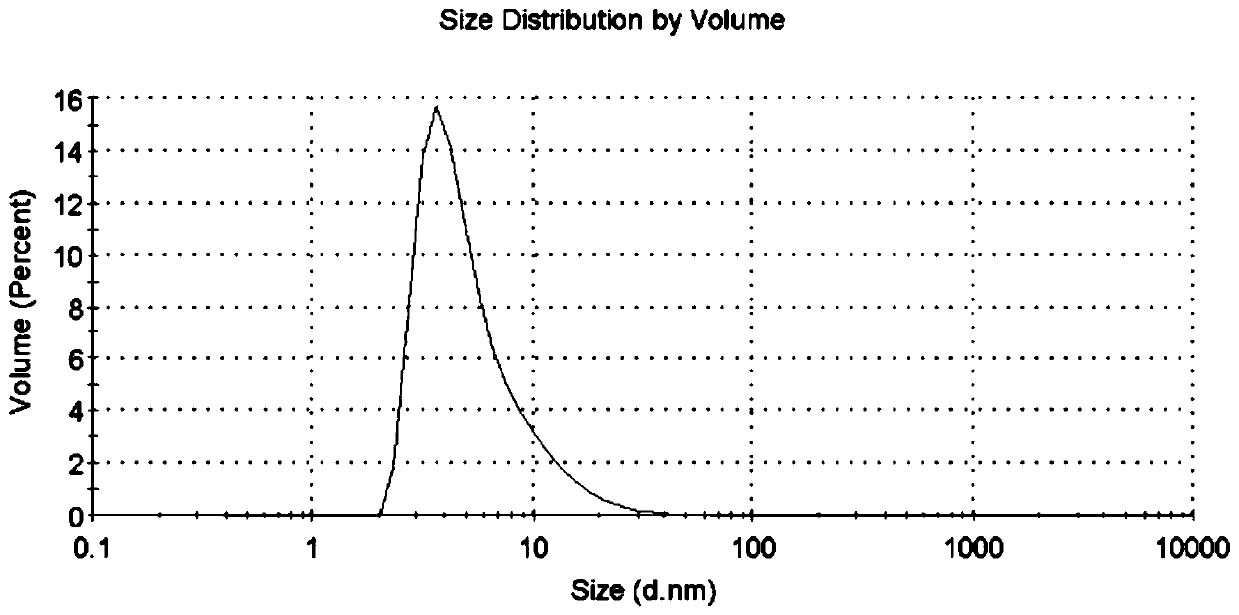

A technology of barium titanate and nano-titanium dioxide, applied in the direction of titanate, alkaline earth metal titanate, etc., can solve the problem that it is difficult to meet the high-quality requirements of barium titanate, the particle size of barium titanate is large, and the particle size distribution is not concentrated, etc. problem, to achieve the effect of reducing production energy consumption and equipment cost, high purity and crystallinity, and narrow distribution interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] At room temperature, uniformly disperse the nano-titanium dioxide powder in deionized water, stir slowly until the mixture is uniform, and obtain 100 g of a nano-titanium dioxide aqueous dispersion with a mass concentration of 48%, which is set aside.

[0073] Under the protection of atmospheric nitrogen atmosphere, 355g of barium hydroxide octahydrate and 150mL of deionized water were added into a three-necked round-bottomed flask, and heated and stirred at 100°C until the barium hydroxide was completely dissolved.

[0074] Quickly add the nano-titanium dioxide aqueous dispersion into the above-mentioned three-necked flask, and maintain the original heating power of the three-necked round-bottomed flask during the addition process, measure the temperature of the obtained mixed system at 97±2°C, continue stirring and raise the temperature to 100°C Reflux reaction for 5h. After the reaction is completed, the reaction product is taken out, filtered, washed and dried to ob...

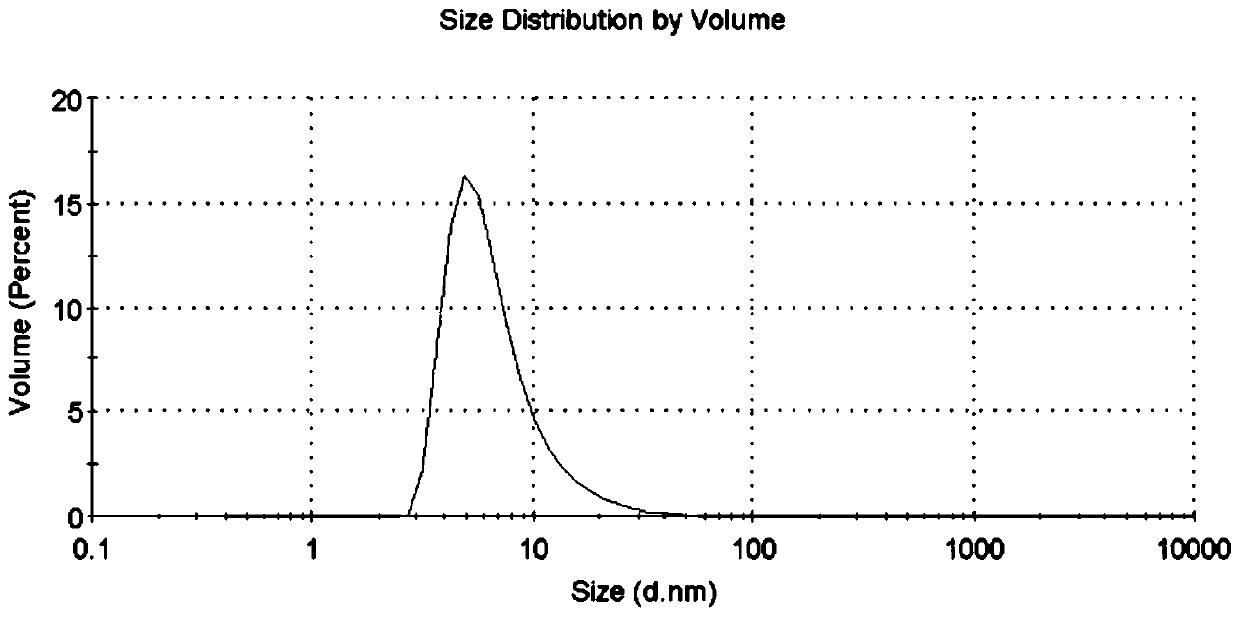

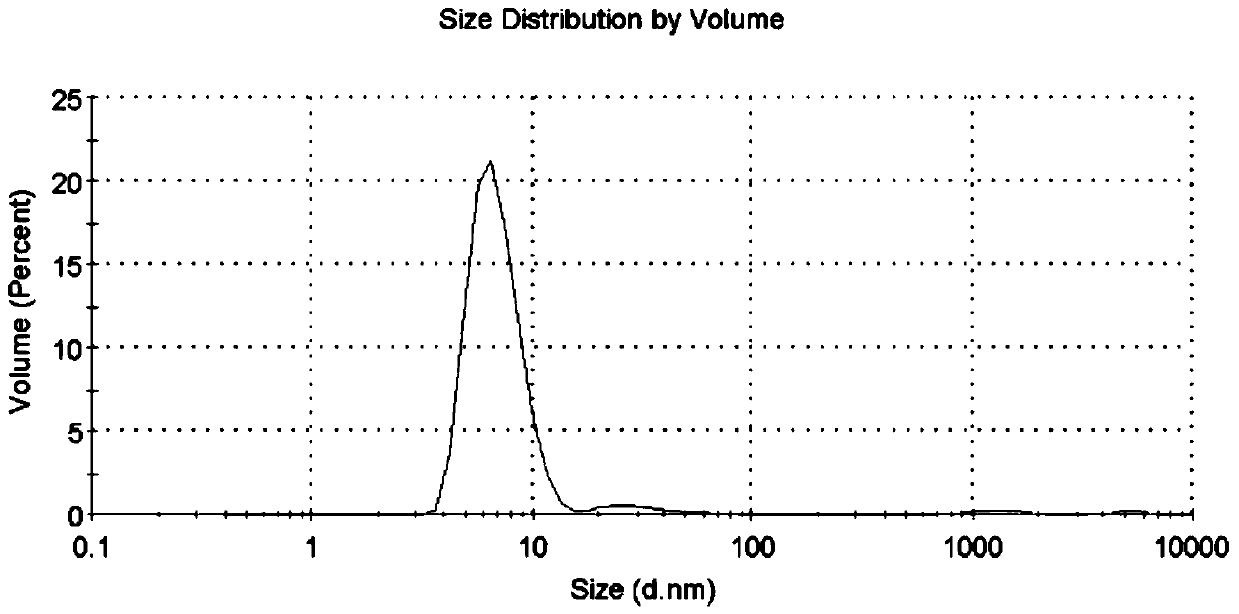

Embodiment 2-3

[0077] The other operating steps in Examples 2-3 were the same as in Example 1, except that the reflux reaction time was changed to 10 h and 20 h respectively, to obtain nano barium titanate crystallites.

Embodiment 4

[0079] Keep the volume of deionized water constant, reduce the mass of titanium dioxide and barium hydroxide to half of the original respectively, then add 51g of sodium hydroxide, and keep the other operating steps consistent with Example 2 to obtain nano-barium titanate microcrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com