Glass fiber reinforced polyethylene glycol terephthalate composite material and preparation thereof

A polyethylene terephthalate and glass fiber technology, which is applied in the field of glass fiber reinforced polyethylene terephthalate composite material and its preparation, can solve the problem of loss of material rigidity, insufficient notched impact strength, material Tensile strength and tensile modulus drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with embodiment.

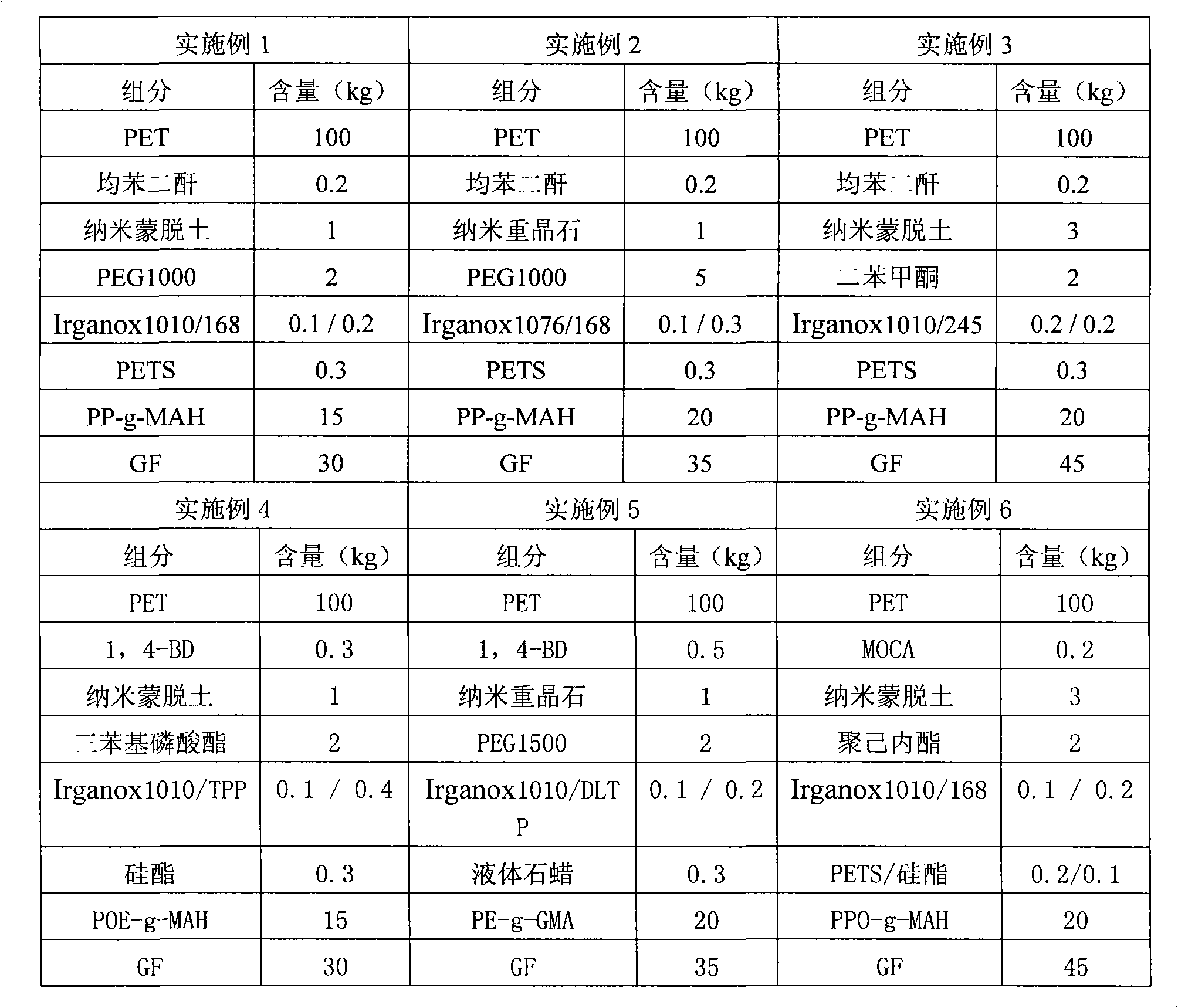

[0025] Embodiments 1 to 6 are prepared according to the formula in Table 1; dry polyethylene terephthalate and toughening agent, chain extender, nucleating agent, crystallization accelerator, antioxidant, lubricant at high speed After stirring evenly in the mixer, put it into the twin-screw extruder from the feeding port. The melt extrusion temperature of the extruder is set in the range of 220-290°C, the vacuum degree is 0.08Pa, and the speed of the main engine is 80-280r / min; glass fiber After surface treatment with silane coupling agent in advance, it needs to be added at the downstream feeding port; the extruded material is cooled, air-dried, pelletized, and after drying, the glass fiber reinforced polyethylene terephthalate composite material is obtained.

[0026] The formula of embodiment is as follows:

[0027] Table 1 embodiment formula

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com