Foaming thermoplastic polyurethane bead and preparation method thereof

A technology of thermoplastic polyurethane and plastic polyurethane, applied in the field of foamed thermoplastic polyurethane beads and its preparation, can solve the problems of coarse size, environmental pollution, etc., achieve the effects of small deformation, high product yield, and avoid size shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

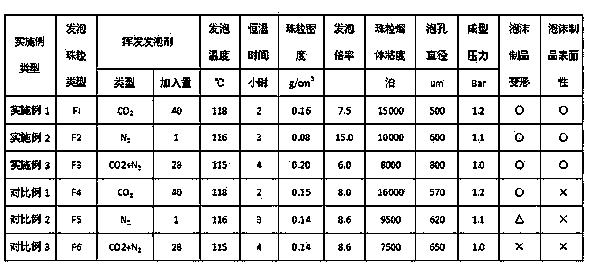

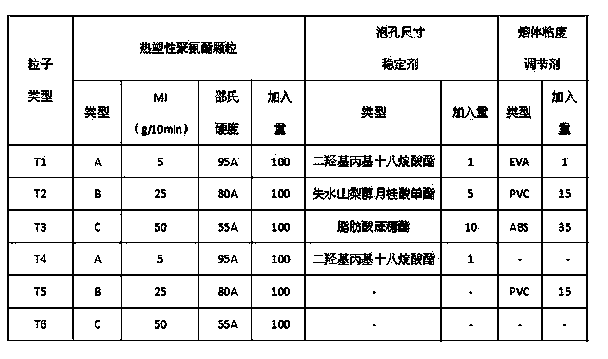

[0042] Embodiment 1, with 100Kg TPU particle A shown in table 1, 1Kg dihydroxypropyl octadecanoate, 1Kg EVA drops into twin-screw extruder after mixing homogeneously by high-speed mixer and carries out melt kneading; Melt kneading The material is extruded into strips from a die head with a diameter of 2 mm in the extruder, then cooled and shaped in a water tank, and cut with a pelletizer to obtain thermoplastic polyurethane particles T1;

[0043] Add 100Kg of thermoplastic polyurethane particles T1 obtained above and 400Kg of water into the autoclave, add 40Kg of carbon dioxide foaming agent while stirring, raise the temperature of the autoclave to 118°C, then keep the temperature at this temperature for 2 hours, and finally Open the discharge valve at the bottom of the autoclave to discharge the mixed solution in the autoclave into the atmosphere, thereby obtaining foamed thermoplastic polyurethane beads F1; the obtained foamed thermoplastic polyurethane beads have a density o...

Embodiment 2

[0045] Embodiment 2, 100Kg TPU particle B shown in table 1, 5Kg sorbitan laurate monoester, 15Kg PVC drop into twin-screw extruder after mixing homogeneously by high-speed mixer and carry out melt kneading; Extrude into strips from a die with a diameter of 2 mm in the extruder, then cool and shape in a water tank, and cut with a pelletizer to obtain thermoplastic polyurethane particles T2;

[0046] Except adopting thermoplastic polyurethane particle T2, foaming temperature is set to 116 ℃, constant temperature is 3 hours, 1Kg nitrogen is used as foaming agent, 1.1 bar of water vapor, obtain foamed thermoplastic polyurethane beads F2 according to the same method as Example 1 Compared with foamed thermoplastic polyurethane molded foam products, performance evaluation is shown in Table 2.

Embodiment 3

[0047] Embodiment 3, 100Kg TPU particle C shown in table 1, 10Kg fatty acid sucrose ester, 35Kg ABS are put into twin-screw extruder after mixing homogeneously by high-speed mixer and melt kneading; Extrude into strips from a die head of 2 mm, then cool and shape in a water tank, and cut with a pelletizer to obtain thermoplastic polyurethane particles T3;

[0048] In addition to using thermoplastic polyurethane particles T3, the foaming temperature is set to 115 ° C, constant temperature for 4 hours, 28Kg of carbon dioxide and nitrogen mixed gas as a foaming agent, 1.0 bar of water vapor; according to the same method as in Example 1 to obtain foaming The performance evaluation of thermoplastic polyurethane beads F3 and foamed thermoplastic polyurethane molded foam products is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com