Method for preparing monodisperse silver-coated microspheres for anisotropic conductive adhesive

An anisotropic, monodisperse technology, applied in the field of preparation of monodisperse silver-plated microspheres, can solve the problems of living environment and safety hazards, high operating temperature, high glass transition temperature, etc. The effect of simplicity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present invention relates to a kind of preparation method of silver-plated melamine formaldehyde resin microsphere, and concrete implementation steps are as follows:

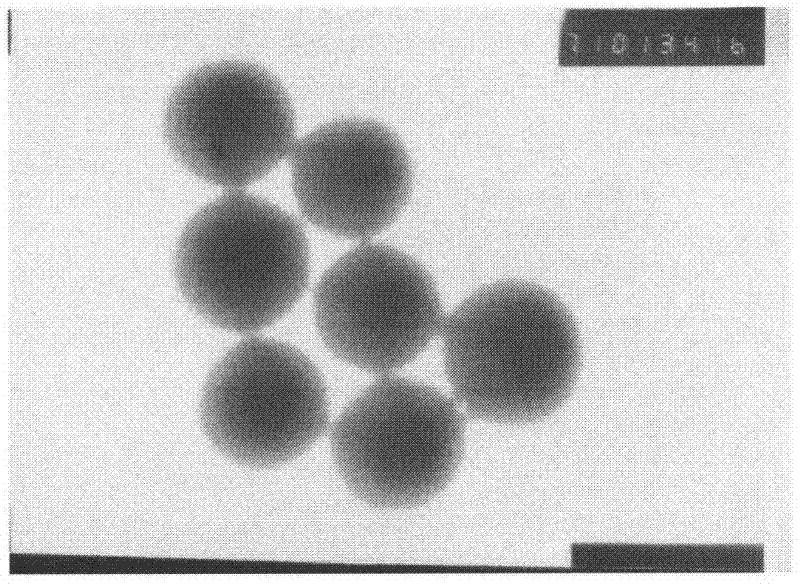

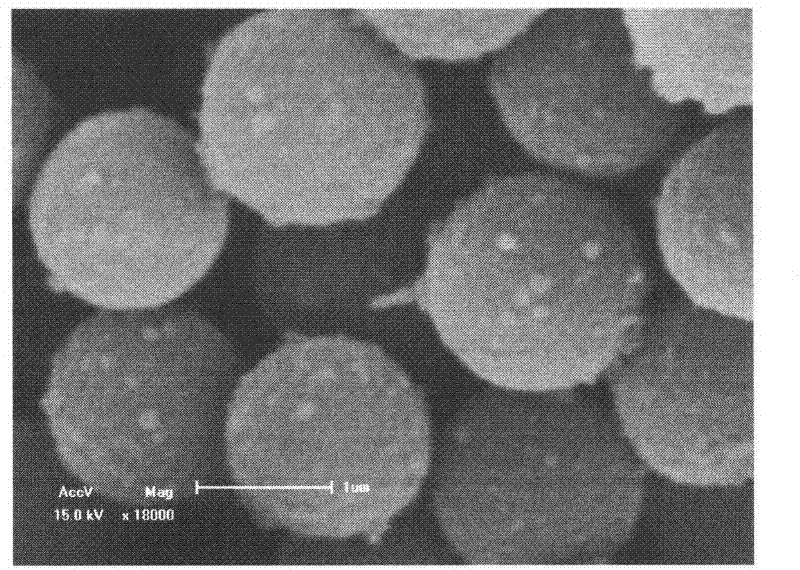

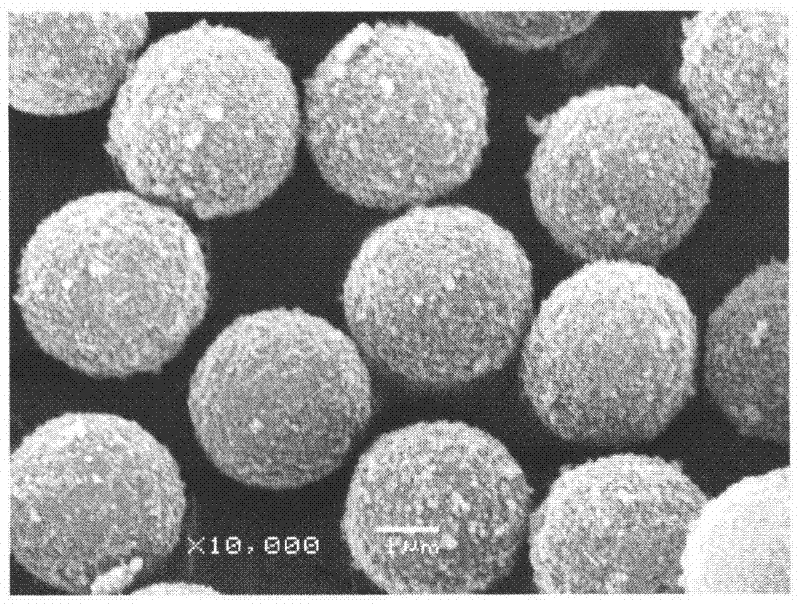

[0041] (1) Preparation of monodisperse melamine-formaldehyde resin microspheres: measure 2.8 g of melamine, 2 mL of formaldehyde solution (37%, at this time the molar ratio of melamine to formaldehyde is about 1:1), and 9 mL of deionized water in a reaction vessel, add Adjust the pH to 9 with an appropriate amount of anhydrous sodium carbonate, heat to 50°C, stir until the reaction becomes clear, and record it as A; the prepared concentration is 4.6×10 -3 g / mL PVA solution, take 90mL and add it to solution A, adjust the pH of the solution to 3 with dilute hydrochloric acid, heat to 60°C, stir and react until the particle size of the microspheres no longer changes (observed with an optical microscope, about 1.5µm, see figure 1 ), centrifuged, washed three times with deionized water, and dried at 60°C ...

Embodiment 2

[0047] The present invention relates to a kind of preparation method of silver-plated melamine formaldehyde resin microsphere, and concrete implementation steps are as follows:

[0048] (1) Preparation of monodisperse melamine-formaldehyde resin microspheres: measure 2.8 g of melamine, 13 mL of formaldehyde solution (37%, at this time the molar ratio of melamine to formaldehyde is about 1:7), and 13 mL of deionized water in a reaction vessel, add Adjust the pH to 9 with an appropriate amount of anhydrous sodium carbonate, heat to 50°C, stir until the reaction becomes clear, and record it as A; the prepared concentration is 4.6×10 -3 g / mL PVA solution, take 95mL and add it to solution A, adjust the pH of the solution to 6 with dilute hydrochloric acid, heat to 60°C, stir and react until the particle size of the microspheres no longer changes (observed with an optical microscope, about 2.5 μm), centrifuged, washed three times with deionized water, and dried at 60°C to obtain the...

Embodiment 3

[0054] The present invention relates to a kind of preparation method of silver-plated melamine formaldehyde resin microsphere, and concrete implementation steps are as follows:

[0055] (1) Preparation of monodisperse melamine-formaldehyde resin microspheres: Measure 2.8 g of melamine, 6 mL of formaldehyde solution (37%, at this time the molar ratio of melamine to formaldehyde is about 1:3.3), 90 mL of deionized water in a reaction vessel, add Adjust the pH to 9 with an appropriate amount of anhydrous sodium carbonate, heat to 50°C, stir until the reaction becomes clear, and record it as A; the prepared concentration is 4.6×10 -3 g / mL PVA solution, take 150mL and add it to solution A, adjust the pH of the solution to 4.5 with dilute hydrochloric acid, heat to 60°C, stir and react until the particle size of the microspheres no longer changes (observed with an optical microscope, about 0.6 μm), centrifuged, washed three times with deionized water, and dried at 60°C to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com