Method of two shot mold metallizing of polymer components

a polymer component and metallizing technology, applied in the field of polymer components, can solve the problems of other steps, dramatically increase the cost of manufacturing the part, and dramatically increase the cost and time required for manufacturing the part, and achieve the effect of high durability and resistance to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

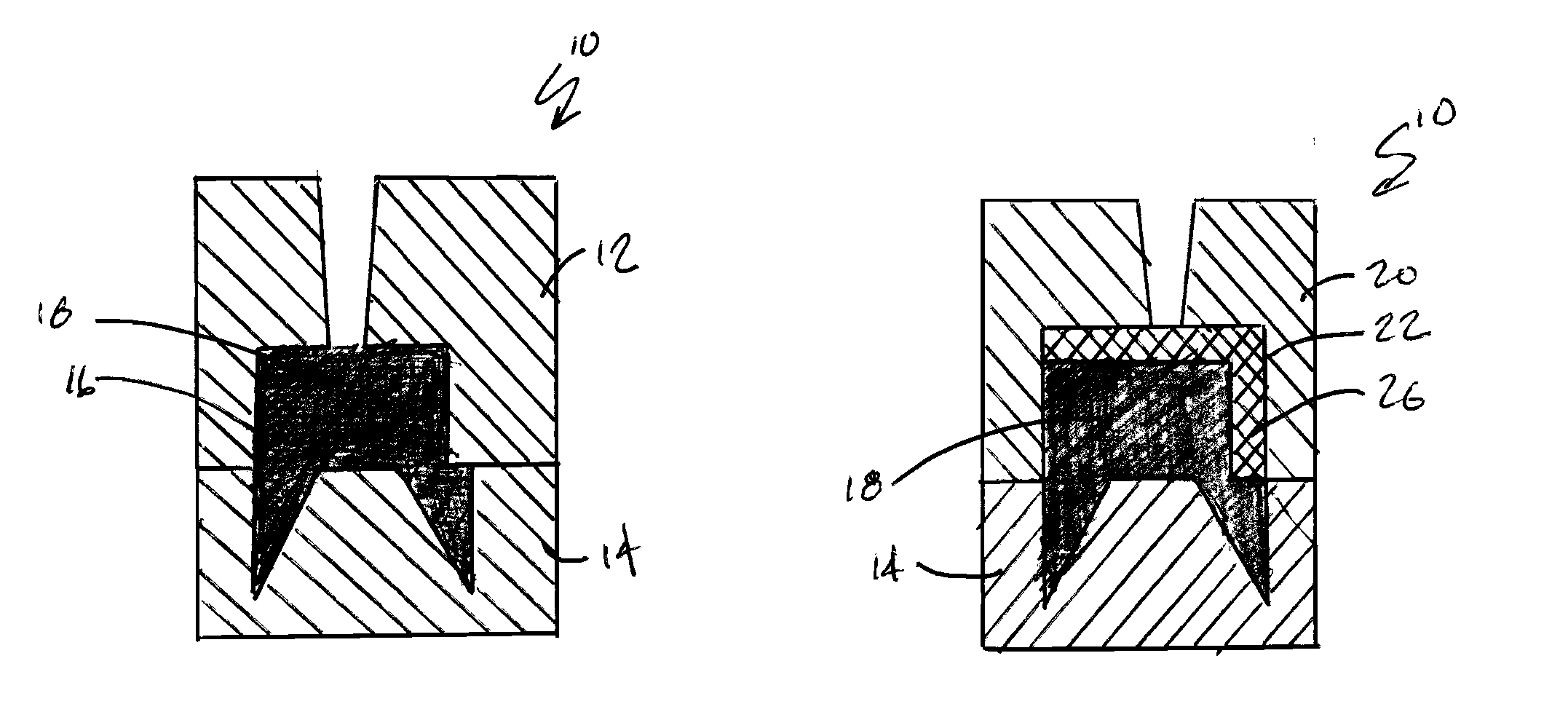

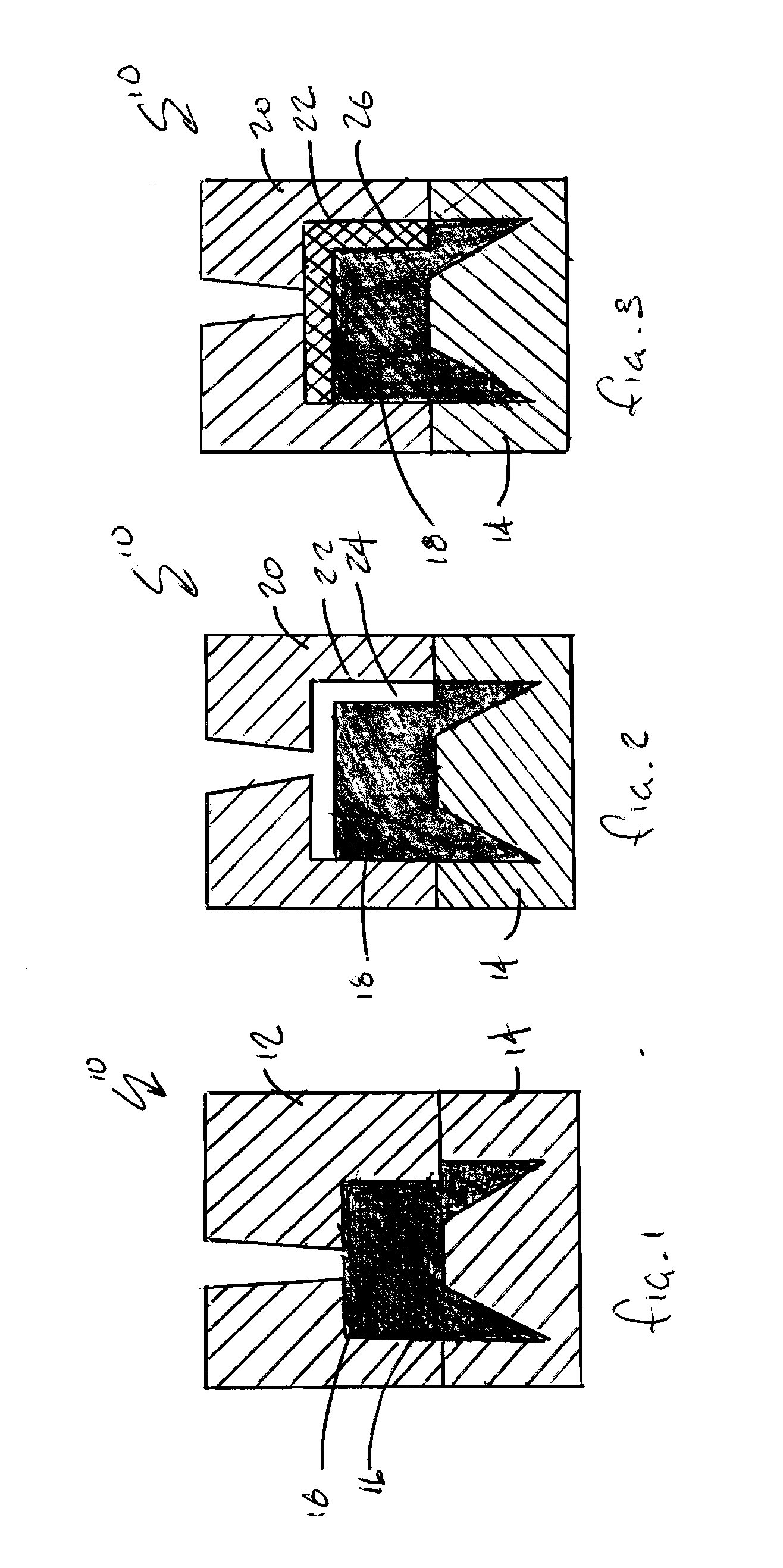

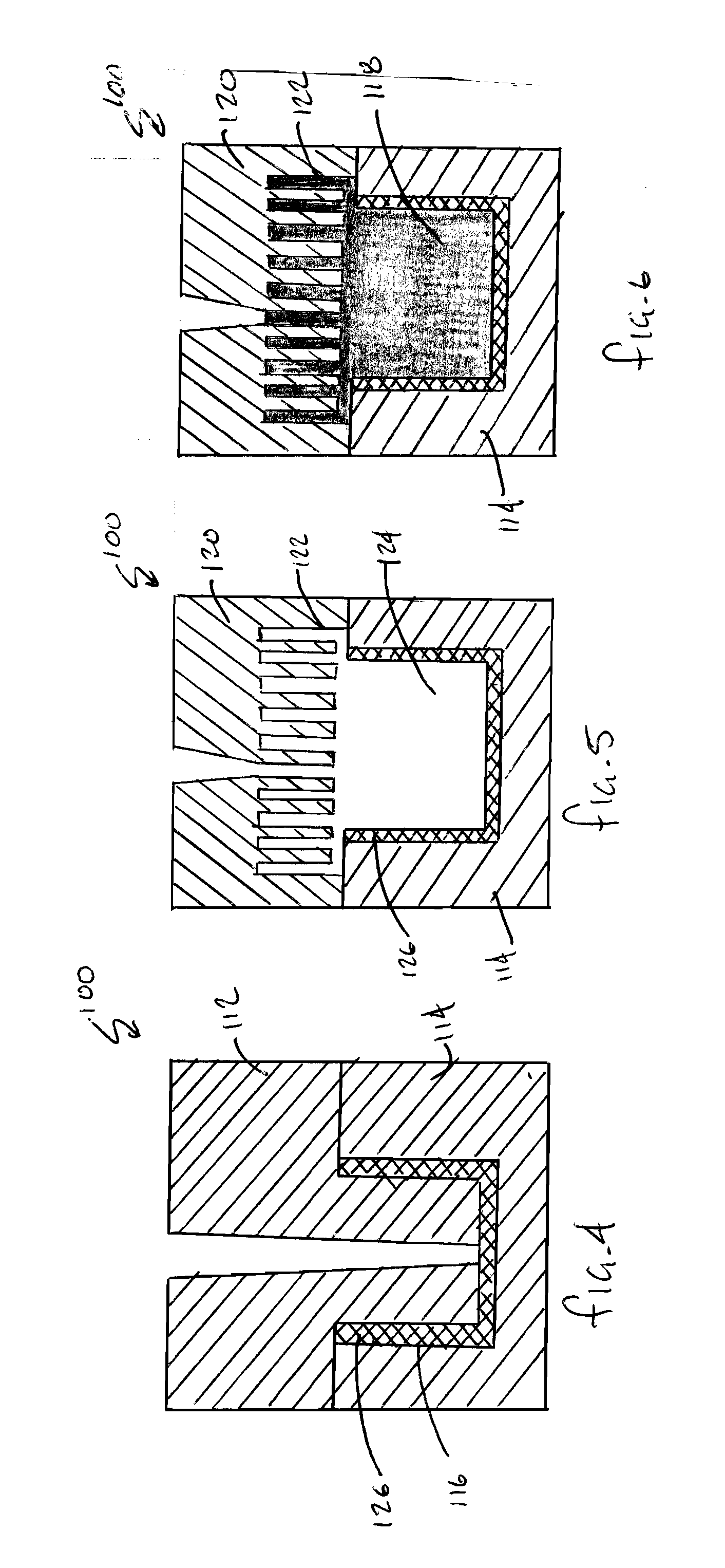

[0028] Now referring to the drawings, the implementation of a first preferred embodiment method of the present invention is shown and generally illustrated in FIGS. 1-3. As was stated above, the method of the present invention is principally directed toward in mold metallization of selected surfaces of molded polymer composite components. More particularly, the method of the present invention is directed to the formation of a net shape molded polymer composite component having a metallic layer about at least one exterior surface thereof. In the context of the present invention, the net shape molding process is a common and well-known process whereby a component part is formed on the interior of a mold cavity wherein the part is in its completed form upon removal from the mold cavity. In this regard, the method of the present invention principally employs a net shape molding process using either a two shot or insert molding technique.

[0029] Turning now to FIGS. 1-3 a method of formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com