Full-solid-waste burn-free foamed concrete based on tail gas carbonization and preparation method and application thereof

A foamed concrete and exhaust technology, which is applied in application, solid waste management, other household appliances, etc., can solve the problems of insignificant solid waste treatment, unfavorable sustainable development, low solid waste content, etc., to solve the problem of exhaust gas utilization. problems, significant economic benefits, effects of utilizing existing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

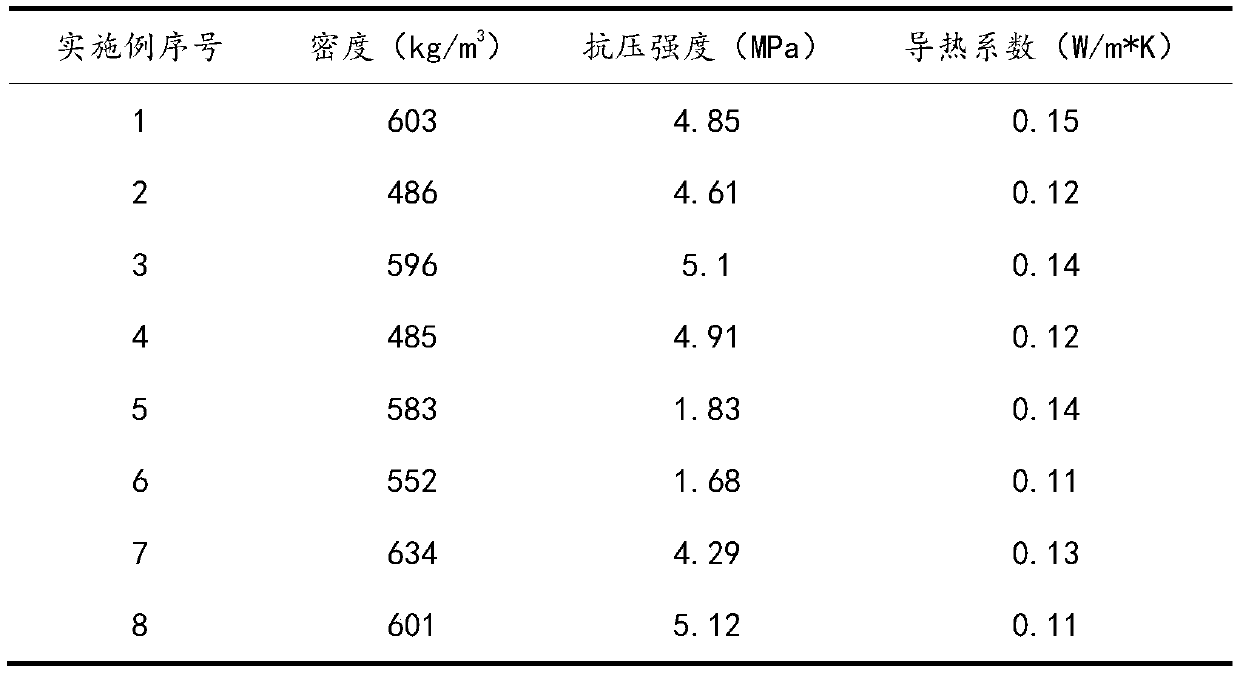

Examples

Embodiment 1

[0039] A method for preparing all-solid waste burning-free foamed concrete based on exhaust gas carbonization, comprising the following steps:

[0040] (1) Put red mud, calcium carbide slag, fly ash, and desulfurized gypsum into the carbonization device first, and pass it into the exhaust gas of the power plant (the concentration of acid gases such as carbon dioxide and sulfur dioxide is between 15-25%), at a temperature of 80 ° C, Carbonization treatment for 3 hours under the conditions of humidity 50% and gas pressure 0.1MPa;

[0041] (2) Mix red mud, calcium carbide slag, fly ash, desulfurized gypsum and chemical waste according to 45%, 35%, 8%, 2%, and 10% carbonized in step (1), and grind to obtain a solid For the mixture, add the solid mixture into the stirring tank, add warm water at 40°C according to the water-cement ratio of 0.2, and add 0.5% of the solid mass of hydrogen peroxide foaming agent and 0.5% of polycarboxylic acid system into the warm water After the water ...

Embodiment 2

[0047] A method for preparing all-solid waste burning-free foamed concrete based on exhaust gas carbonization, comprising the following steps:

[0048] (1) Put red mud, calcium carbide slag, fly ash, and phosphogypsum into the carbonization device first, and pass it into the exhaust gas of the power plant (the concentration of acid gases such as carbon dioxide and sulfur dioxide is between 15-25%), at a temperature of 75 ° C, Carbonization treatment for 2 hours under the conditions of humidity 50% and gas pressure 0.13MPa;

[0049] (2) Red mud, calcium carbide slag, fly ash, phosphogypsum and chemical waste (salt mud) after carbonization in step (1), its main component is: Mg(OH) 2 , CaCO 3 , BaSO 4 and silt, etc.) according to the ratio of 35%, 50%, 6%, 2%, 4%, mixed evenly, pulverized, and then passed through a 180-mesh square hole sieve to obtain a solid mixture, which was added to the mixing tank, according to Add 0.18 water-cement ratio to warm water at 20°C, add 1.5% ...

Embodiment 3

[0051] A method for preparing all-solid waste burning-free foamed concrete based on exhaust gas carbonization, comprising the following steps:

[0052] (1) Put red mud, calcium carbide slag, fly ash, and fluorogypsum into the carbonization device first, and then pass it into the exhaust gas of the power plant (the concentration of acid gases such as carbon dioxide and sulfur dioxide is between 15-25%), at a temperature of 95 ° C, Carbonization treatment for 3.5 hours under the conditions of humidity 55% and gas pressure 0.18MPa;

[0053] (2) Red mud, calcium carbide slag, fly ash, fluorogypsum and chemical waste (salt mud) after carbonization in step (1), its main component is: Mg(OH) 2 , CaCO 3 , BaSO 4 and silt, etc.) according to the ratio of 62%, 25%, 2%, 11%, 10%, mixed uniformly, ground, and then passed through a 150-mesh square hole sieve to obtain a solid mixture, and the solid mixture was added to the mixing tank, according to Add warm water at 50°C to a water-ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com