A kind of magnetic levitation train brake pad material and its preparation method

A technology for maglev trains and brake pads, applied in the field of brake pads, can solve problems such as low dynamic and static friction coefficients, large fluctuations in friction coefficients, and high train operating costs, achieving good weldability, improving friction coefficients, and reducing operating and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

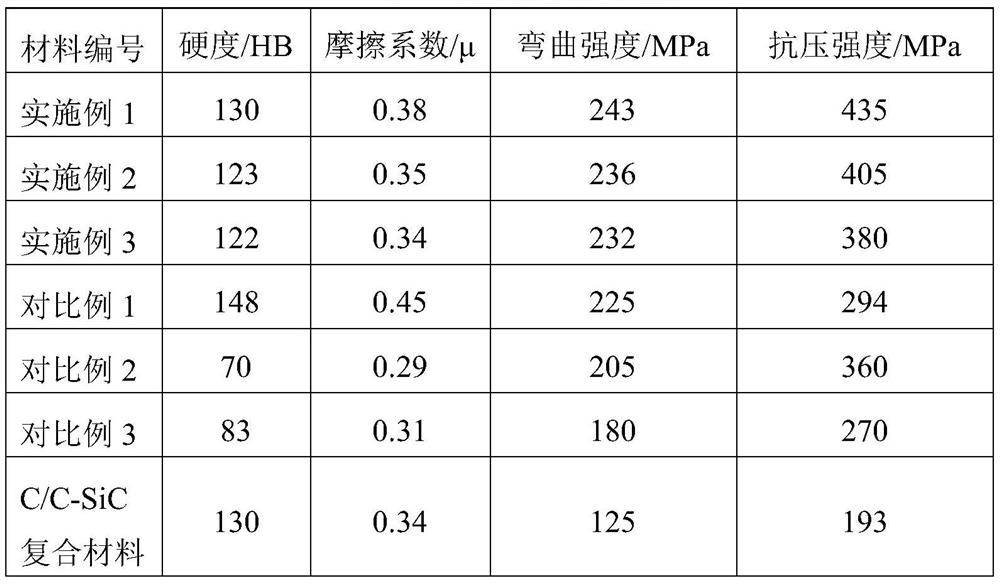

Examples

Embodiment 1

[0060] A brake pad material for a magnetic levitation train, the raw material comprises the following components in parts by weight:

[0061] Pre-alloyed powder 100 parts, MoS 2 Powder 5 parts, Mo 2 o 3 2 parts of Cr powder, 3 parts of Cr powder, SiO 2 5 parts of graphite powder and 12 parts of scaly graphite. The pre-alloyed powder is a combination of Fe-Al powder and Fe-Cu powder.

[0062] Wherein, the particle size of the pre-alloyed powder is <75 μm.

[0063] In Fe-Al powder, the mass ratio of Fe powder to Al powder is 4.5:1.

[0064] In Fe-Cu powder, the mass ratio of Fe powder to Cu powder is 4.5:1.

Embodiment 2

[0066] A brake pad material for a magnetic levitation train, the raw material comprises the following components in parts by weight:

[0067] Pre-alloyed powder 100 parts, MoS 2 Powder 5 parts, Mo 2 o 3 2 parts of Cr powder, 3 parts of Cr powder, SiO 2 5 parts of graphite powder and 12 parts of scaly graphite. The pre-alloyed powder is a combination of Fe-Al powder and Cu-Al powder.

[0068] Wherein, the particle size of the pre-alloyed powder is <75 μm.

[0069] In Fe-Al powder, the mass ratio of Fe powder to Al powder is 4.5:1.

[0070] In Cu-Al powder, the mass ratio of Cu powder to Al powder is 10:1.

Embodiment 3

[0072] A brake pad material for a magnetic levitation train, the raw material comprises the following components in parts by weight:

[0073] Pre-alloyed powder 100 parts, MoS 2 Powder 5 parts, Mo 2 o 3 2 parts of Cr powder, 3 parts of Cr powder, SiO 2 5 parts of graphite powder and 12 parts of scaly graphite. The pre-alloyed powder is a combination of Fe-Cu powder and Cu-Al powder.

[0074] Wherein, the particle size of the pre-alloyed powder is <75 μm.

[0075] In Fe-Cu powder, the mass ratio of Fe powder to Cu powder is 4.5:1.

[0076] In Cu-Al powder, the mass ratio of Cu powder to Al powder is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com