A kind of antistatic pressure-sensitive adhesive and its preparation method and antistatic pressure-sensitive adhesive tape

A voltage-sensitive adhesive technology, applied in pressure-sensitive films/sheets, adhesives, conductive adhesives, etc., to achieve strong weather resistance, energy saving and environmental protection in production, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

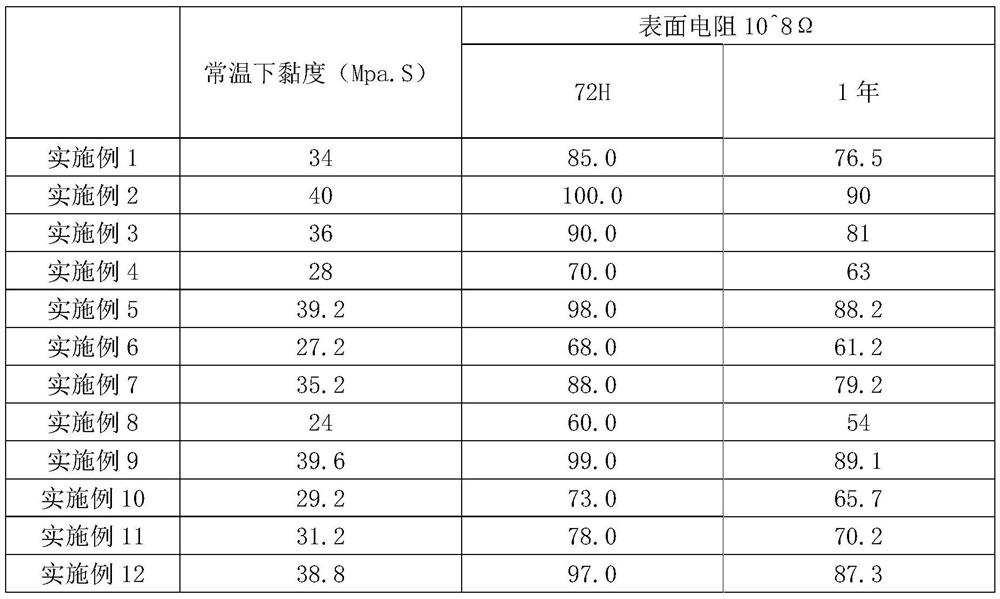

Examples

Embodiment 1

[0026] This embodiment provides an antistatic pressure-sensitive adhesive, comprising the following components by weight: 20 parts by weight of 1,6-hexanediol diacrylate gel, 30 parts by weight of isooctyl acrylate, 3 parts by weight of AA refined acrylic acid, 12 parts by weight of 1-hydroxycyclohexyl phenyl ketone, 18 parts by weight of dodecanethiol and 5 parts by weight of poly(3,4-ethylenedioxythiophene).

[0027] The preparation method of the antistatic pressure-sensitive adhesive is as follows: firstly mix 1,6-hexanediol diacrylate gel and poly(3,4-ethylenedioxythiophene) to form a complex, and then add isooctyl acrylate Ester, 1-hydroxycyclohexyl phenyl ketone, dodecyl mercaptan, add into the container and stir evenly, finally add AA refined acrylic acid under the light of intensity 2200lex and wavelength 500nm; glue.

[0028] How to use: put the prepared antistatic pressure sensitive adhesive into a foaming machine and spread it on the front and back sides of the sub...

Embodiment 2、3、4、5、6、7、8、9、10、11、12

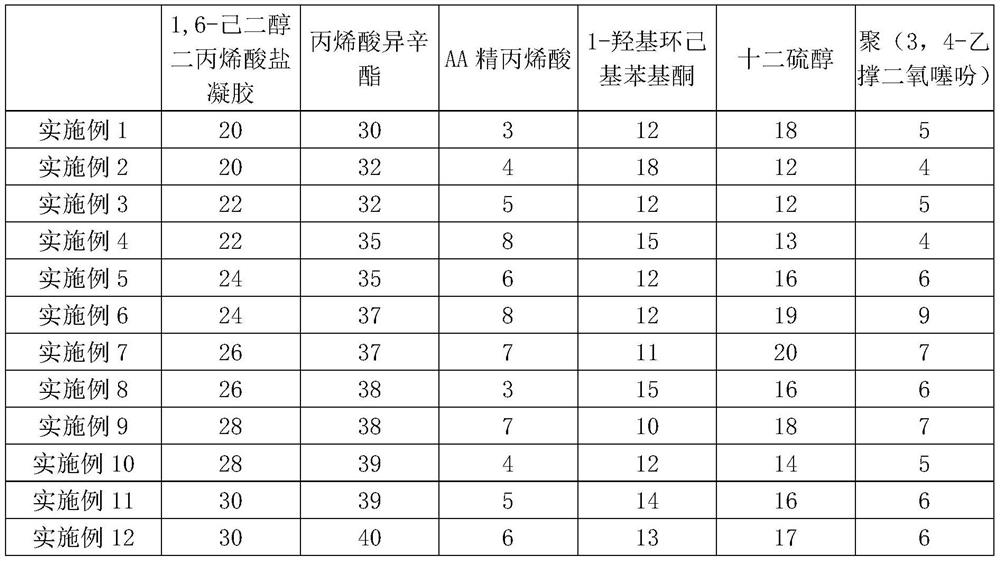

[0029] Embodiment 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 The preparation method is as embodiment 1, and the formula is as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com