Magnetic conductive pressure-sensitive adhesive, preparation method thereof and magnetic conductive adhesive tape

A technology of pressure-sensitive adhesive and magnetic conduction, which is applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive additive, etc. It can solve the problems of complicated packaging operation of pressure-sensitive adhesive and cannot be torn off multiple times, and achieves strong weather resistance and viscosity. The effect of small changes and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a magnetically conductive pressure-sensitive adhesive, comprising the following components by weight: 15 parts by weight of 1,6-hexanediol diacrylate gel, 30 parts by weight of isooctyl acrylate, 30 parts by weight of AA refined acrylic acid, 12 parts by weight of 1-hydroxycyclohexyl phenyl ketone, 15 parts by weight of dodecanethiol and 3 parts by weight of magnetic powder.

[0025] The preparation method of the magnetically conductive pressure-sensitive adhesive is as follows: firstly mix 1,6-hexanediol diacrylate gel and magnetic powder uniformly, then add isooctyl acrylate, 1-hydroxycyclohexyl phenyl ketone, dodecyl Mercaptan was added to the container and stirred evenly, and finally AA refined acrylic acid was added under the light of intensity 2200lex and wavelength of 500nm; the light was stirred for 20-50min to prepare the magnetically conductive pressure-sensitive adhesive of Example 1.

[0026] Use and measurement method: Coat the prep...

Embodiment 2、3、4、5、6、7、8、9、10、11、12

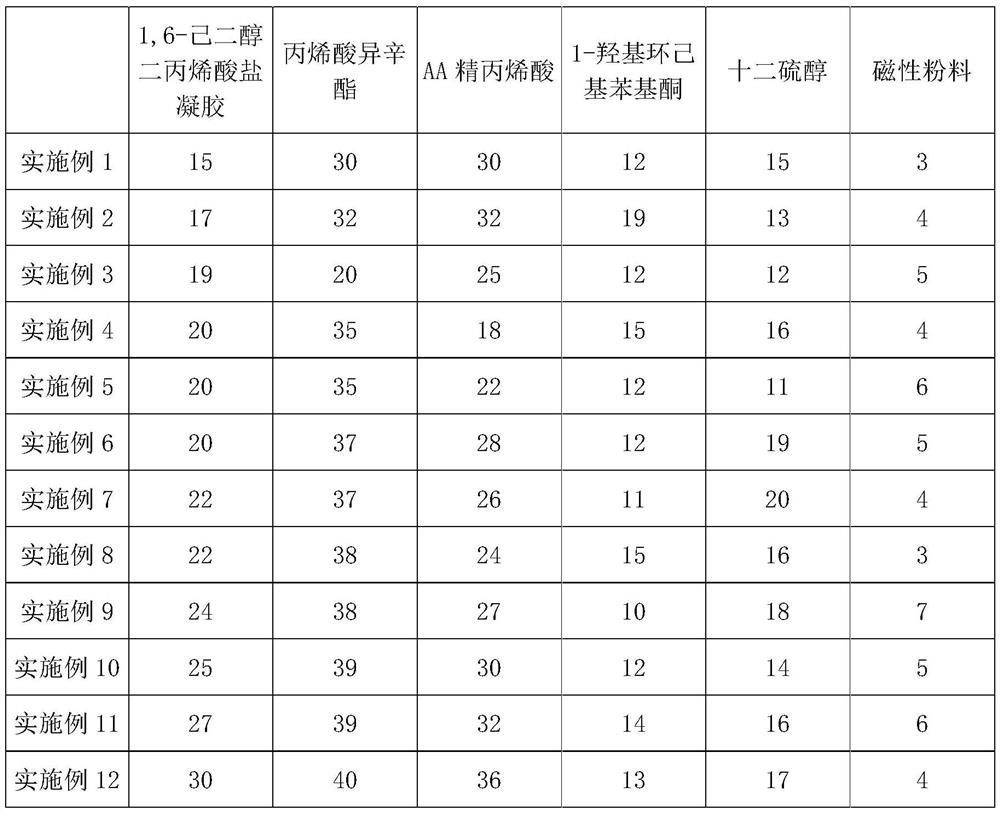

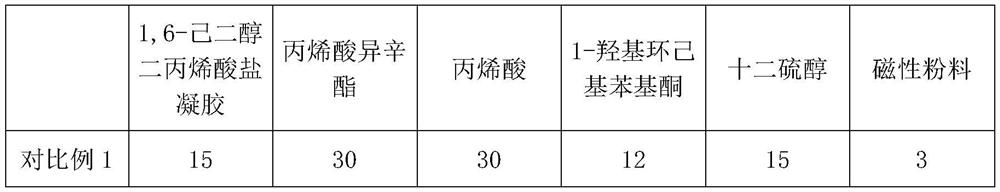

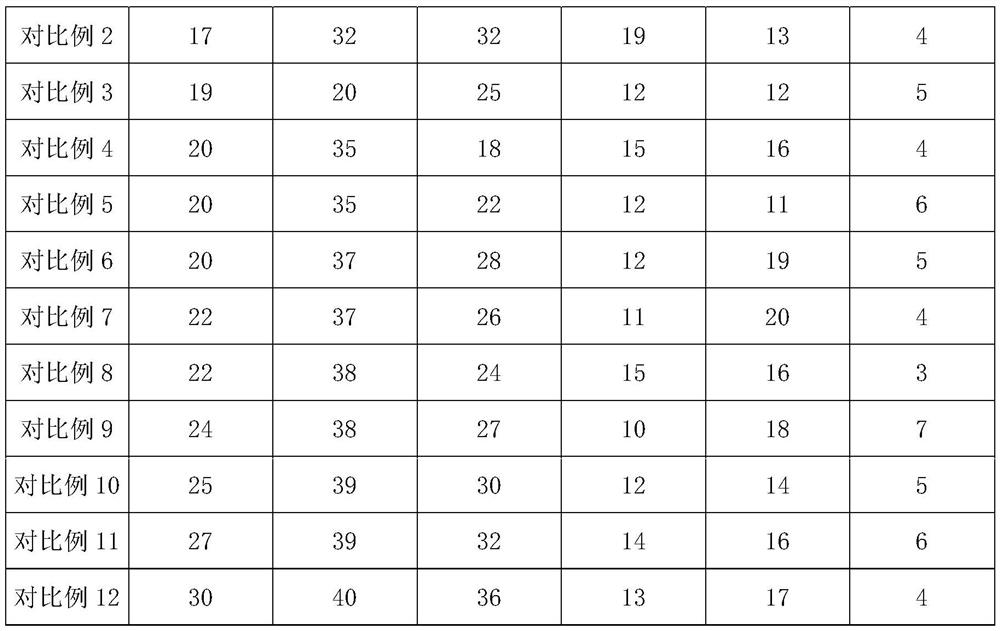

[0027] Embodiment 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 The preparation method is as embodiment 1, and the formula is as follows:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com