Electrochemical catalysis synthesis method of 3-sulfonyl substituted oxo indoles compound

A compound, sulfonic acid group technology, applied in the field of electrochemical catalysis synthesis, can solve problems such as synthetic methods that have not been reported in domestic and foreign literature, chemical waste heavy metal pollution, environmental and human harm, etc. The effect of low equipment cost and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

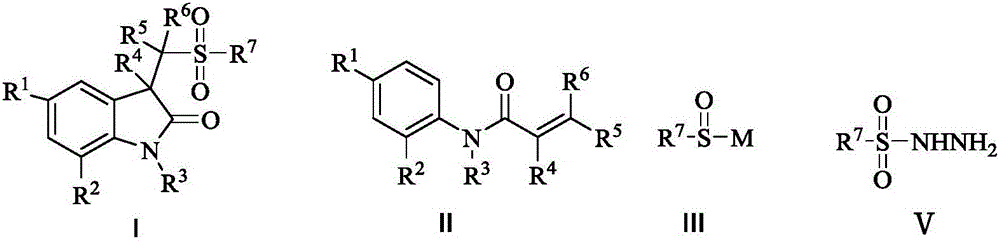

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

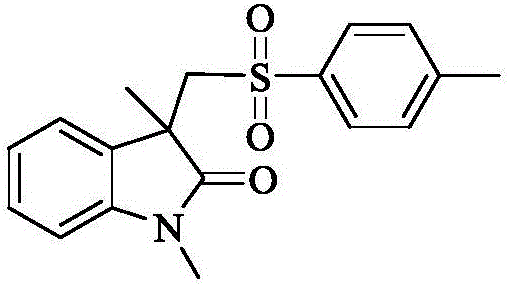

[0035] Embodiment 1: The electrochemical synthesis of 1,3-dimethyl-3-((4-methylbenzenesulfonic acid group) methyl) indolone

[0036] In a 50 mL single-chamber electrolytic cell, N-methyl-N-phenylmethacrylamide (1.0 mmol), sodium p-toluenesulfinate (3 mmol) and ammonium bromide (0.1 mmol) were added to 1 , 4-dioxane: water = 1:1, in a total of 12mL solution, with 2.5×1cm 2 Graphite sheets for the anode and cathode, at 2mA / cm 2 Electrolyze at a constant current, stir at 80°C, stop electrolysis when energized for 8 hours, remove the solvent by rotary evaporation, extract three times with dichloromethane, and separate by column chromatography to obtain 1,3-dimethyl-3-((4 -tosylate)methyl)indolinone. Yield: 73%.

[0037]

[0038] White solid; mp:131-133℃; 1 H NMR (400MHz, CDCl 3 )δ1.40(s,3H),2.41(s,3H),3.18(s,3H),3.68(d,J=14.4Hz,1H),3.87(d,J=14.4Hz,1H),6.86( d, J=7.6Hz, 1H), 6.94(t, J=7.6Hz, 1H), 7.10(d, J=7.2Hz, 1H), 7.18(d, J=8.0Hz, 2H), 7.31(t, J=10.8Hz, 1H), 7.40(d, J...

Embodiment 2

[0039] Embodiment 2: The electrochemical synthesis of 1,3-dimethyl-3-((4-methylbenzenesulfonic acid group) methyl) indolinone

[0040] In a 50 mL single-chamber electrolytic cell, N-methyl-N-phenylmethacrylamide (1.0 mmol), sodium p-toluenesulfinate (3 mmol) and ammonium bromide (0.5 mmol) were added to 1 , 4-dioxane: water = 1:1, in a total of 12mL solution, with 2.5×1cm 2 Graphite sheets for the anode and cathode, at 2mA / cm 2 Electrolyze at a constant current, stir at 80°C, stop electrolysis when energized for 8 hours, remove the solvent by rotary evaporation, extract three times with dichloromethane, and separate by column chromatography to obtain 1,3-dimethyl-3-((4 -tosylate)methyl)indolinone. Yield: 71%.

Embodiment 3

[0041] Embodiment 3: The electrochemical synthesis of 1,3-dimethyl-3-((4-methylbenzenesulfonic acid group) methyl) indolinone

[0042] In a 50 mL single-chamber electrolytic cell, N-methyl-N-phenylmethacrylamide (1.0 mmol), sodium p-toluenesulfinate (3 mmol) and ammonium bromide (0.5 mmol) were added to acetonitrile : Water=1:1, in a total of 12mL solution, with 2.5×1cm 2 Graphite sheets for the anode and cathode, at 2mA / cm 2 Electrolyze at a constant current, stir at 80°C, stop electrolysis when energized for 8 hours, remove the solvent by rotary evaporation, extract three times with dichloromethane, and separate by column chromatography to obtain 1,3-dimethyl-3-((4 -tosylate)methyl)indolinone. Yield: 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com