Method and equipment for processing chemicals waste water by catalytic oxidation of activated carbon induced by microwaves

A technology of catalytic oxidation and activated carbon, which is applied in the field of water treatment, can solve the problems of large biochemical differences and damage to the stable operation of the biochemical treatment system, and achieve the effect of simple operation, low one-time input cost of the system, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

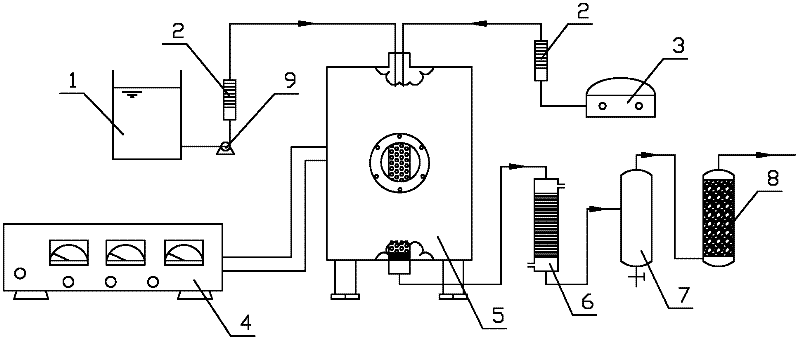

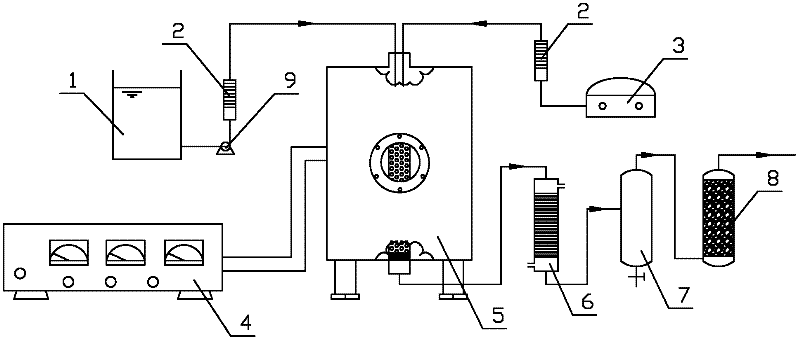

[0026] See figure 1 , a device for realizing microwave-induced activated carbon catalytic oxidation treatment of chemical wastewater, including activated carbon reaction bed 5, microwave generator 4, water inlet pool 1, water inlet lift pump 9, air pump 3, condenser 6, gas-liquid separator 7 and tail gas absorption device, the top of the activated carbon reaction bed 5 is provided with waste water and air inlets, the side is provided with microwave inlets, and the bottom is provided with treated waste water outlets, the waste water and air inlets are connected to the air pump 3, And it is connected with the water inlet pool 1 through the water inlet lift pump 9, the microwave inlet is connected with the microwave generator 4, the waste water outlet after the treatment is connected with the inlet of the condenser 6, and the outlet of the condenser 6 Outlet is connected with the inlet of described gas-liquid separator 7, and described gas-liquid separator 7 is provided with the ...

Embodiment 2

[0030] See figure 1 , a device for microwave-induced activated carbon catalytic oxidation treatment of chemical wastewater, the difference from Example 1 is that the activated carbon in the activated carbon reaction bed 5 is coconut shell carbon, and the particle size of coconut shell carbon is 0.5-2.8mm ; Tail gas absorption device is: activated carbon fiber absorption tower. Use the above-mentioned equipment to take the actual chemical tank washing wastewater as the treatment object, and the influent COD is 8500mg / L. The operation steps of the equipment are the same as in Example 1, and the operating parameters are as follows: the hydraulic retention time of the control wastewater in the activated carbon reaction bed 5 is 90min , the air intake volume is 2000L / min, and the microwave power is 150KW.

[0031] After testing, the COD of the purified waste liquid was reduced to 75mg / L.

Embodiment 3

[0033] See figure 1 , a device for microwave-induced activated carbon catalytic oxidation treatment of chemical wastewater, the difference from Example 1 is that the activated carbon in the activated carbon reaction bed 5 is fruit shell carbon, and the particle size of the shell carbon is 18-20 mm. The tail gas absorption device is: epoxy resin absorption tower. Use the above-mentioned equipment to take the actual chemical tank washing wastewater as the treatment object, and the influent COD is 4995mg / L. The operation steps of the equipment are the same as in Example 1, and the operating parameters are as follows: the hydraulic retention time of the control wastewater in the activated carbon reaction bed 5 is 150min , the air intake volume is 5000L / min, and the microwave power is 150W.

[0034] After testing, the COD of the purified waste liquid was reduced to 53mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com