High-calcium edible salt produced by calcium-containing mirabilite-type mineral halide and producing method thereof

A technology of glauberite and edible salt, which is applied in the field of high-calcium edible salt and the production of the high-calcium edible salt, which can solve the problems that rock salt-associated glauberite has no mineral resource exploitation and utilization, and rock salt-associated glauberite resources cannot be exploited, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

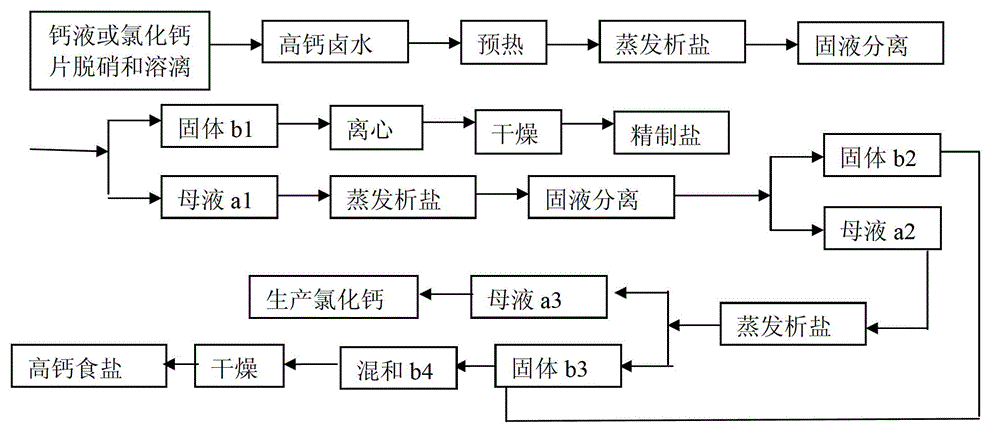

Image

Examples

Embodiment 1

[0077] First, according to the method described in the patent 201110006672.X, the distillation waste liquid containing 90g / L calcium chloride and 40g / L sodium chloride (that is, ammonia alkali waste liquid) produced by soda ash production is used instead of 50% fresh water to inject Glauber’s salt type Mining brine in the mine to produce CaCl 2 High-calcium brine with a content of 20g / L and a NaCl content of 290g / L; secondly, use a multi-effect evaporator (Shanghai Dingtai Evaporator Co., Ltd., evaporator + Austrian Reichenhall company, MVR) to evaporate and concentrate the above-mentioned calcium-containing brine (work The parameters are: temperature 60°C, pressure 0.05Mpa, evaporation, concentration and crystallization until the calcium chloride in the solution reaches 150g / L), the feed liquid passes through the liquid cyclone separator, and the mother liquid a1 and sodium chloride crystal solid b1 are separated. Sodium chloride crystal b1 is separated as a product, washed w...

Embodiment 2

[0080] First, according to the method described in the patent 201110006672.X, the distillation waste liquid containing 100g / L calcium chloride and 50g / L sodium chloride produced by soda ash production is used instead of all fresh water to inject mirabilite-type mines for brine mining to produce CaCl 2 High-calcium brine with a content of 70g / L and a NaCl content of 250g / L; secondly, a multi-effect evaporator (Shanghai Dingtai Evaporator Co., Ltd., evaporator + Austrian Reichenhall company, MVR) evaporates and concentrates the above-mentioned calcium-containing brine (working parameters It is: temperature 90°C, pressure 0.09Mpa, evaporating, concentrating and crystallizing until the calcium chloride in the solution reaches 200g / L), the feed liquid passes through the liquid cyclone separator, and the mother liquid a1 and sodium chloride crystal solid b1 are separated. The sodium chloride crystal b1 is separated as a product, then washed with saturated brine, dehydrated by a centr...

Embodiment 3

[0082] First, according to the method described in the patent 201110006672.X, the distillation waste liquid containing 130g / L calcium chloride and 60g / L sodium chloride produced by soda ash production is used instead of 50% fresh water to inject mirabilite-type mines for brine mining to produce CaCl 2 High-calcium brine with a content of 50g / L and a NaCl content of 280g / L; secondly, a multi-effect evaporator (Shanghai Dingtai Evaporator Co., Ltd., evaporator + Austrian Reichenhall company, MVR) evaporates and concentrates the above-mentioned calcium-containing brine (working parameters It is: temperature 120°C, pressure 0.10Mpa, evaporating, concentrating and crystallizing until the calcium chloride in the solution reaches 180g / L), the feed liquid is passed through a hydrocyclone, and the mother liquid a1 and sodium chloride crystal solid b1 are separated. The sodium chloride crystal b1 is separated as a product, then washed with saturated brine, dehydrated by a centrifuge, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com