A kind of nano-calcium carbonate used for intestinal lead removal

A nano-calcium carbonate and lead removal technology, applied in the field of nano-materials, can solve the problems of uneven particle size distribution of nano-calcium carbonate, lack of lead removal effect in the intestinal tract, and unstable crystal form control, so as to speed up the precipitation replacement reaction, The effect of increasing the burden on the kidneys and enhancing the lead removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

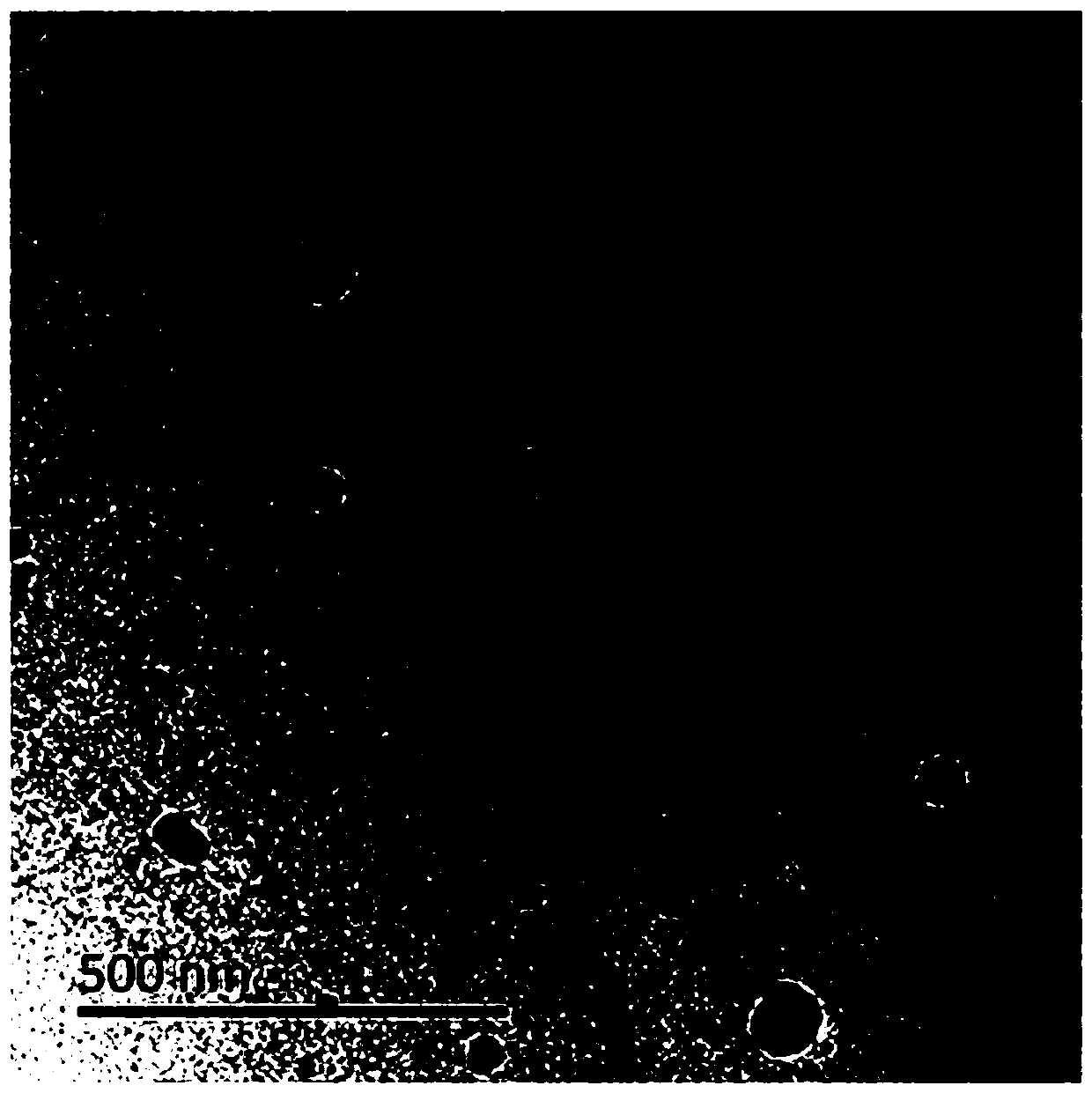

[0022] Weigh 5.3 g Na 2 CO 3 The powder was dissolved in 25mL double distilled water, in Na 2 CO 3 EDTA (2%, w / w-Na 2 CO 3 ) and Na 2 HPO 4 (2%, w / w-Na 2 CO 3 ), reacted for 10 minutes; then stirred with PEG 1000 (10%, w / w-CaCl 2 ) of 5.55g CaCl 2 Solution 25mL was slowly added dropwise to the above Na 2 CO 3 In the mixed solution, the rate of addition is 1 drop / second, and the concentration of the slurry is 10%. After fully reacting for 30 minutes, add sodium polyacrylate solution (1%, w / w-CaCl 2 )50mL, intermittently sonicate for 20 minutes, that is, every 5 seconds of ultrasonication, intermittently for 5 seconds; let stand at room temperature for 24 hours, collect the precipitate by centrifugation, wash three times with double distilled water, and wash three times with absolute ethanol; dry the precipitate in an oven, then Obtain nanometer calcium carbonate powder. Among them, "EDTA (2%, w / w-Na 2 CO 3 )” means that the mass of EDTA accounts for Na 2 CO 3 2...

Embodiment 2

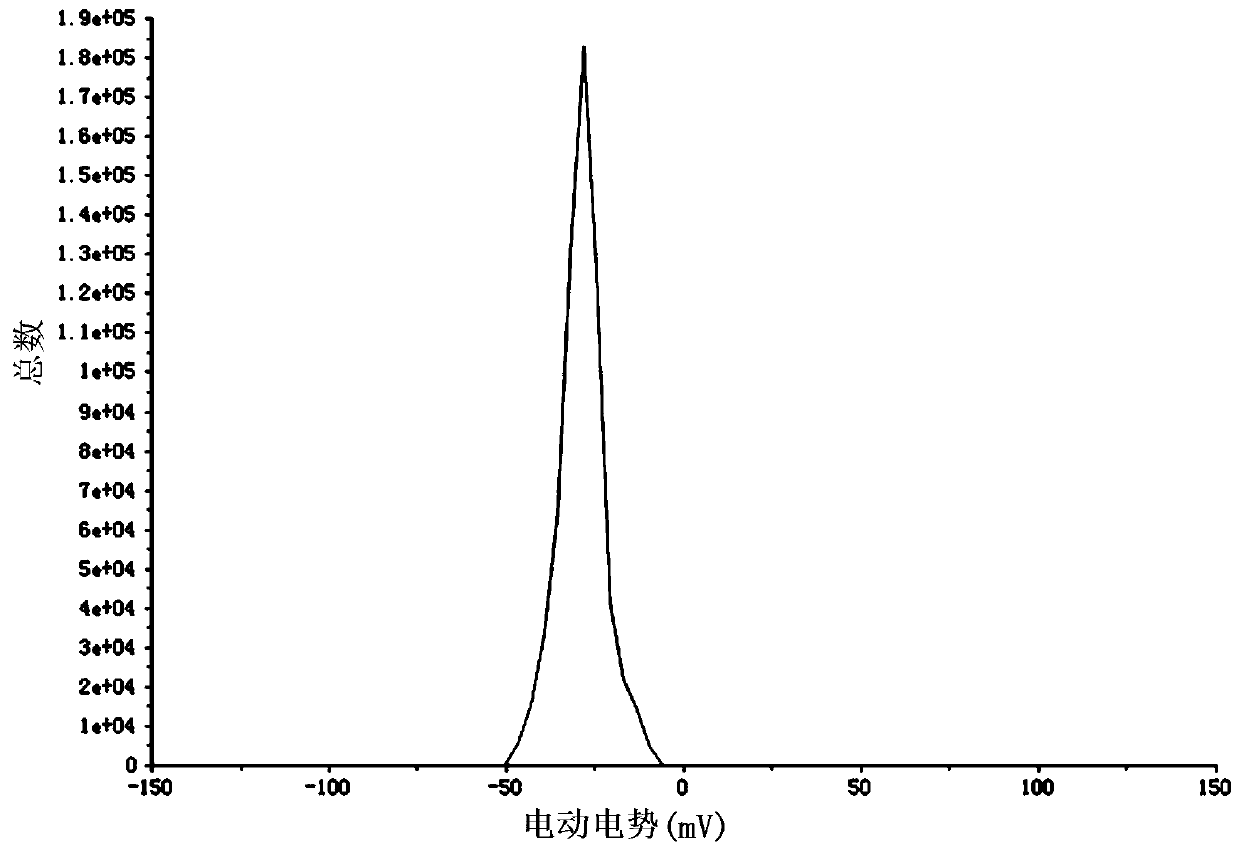

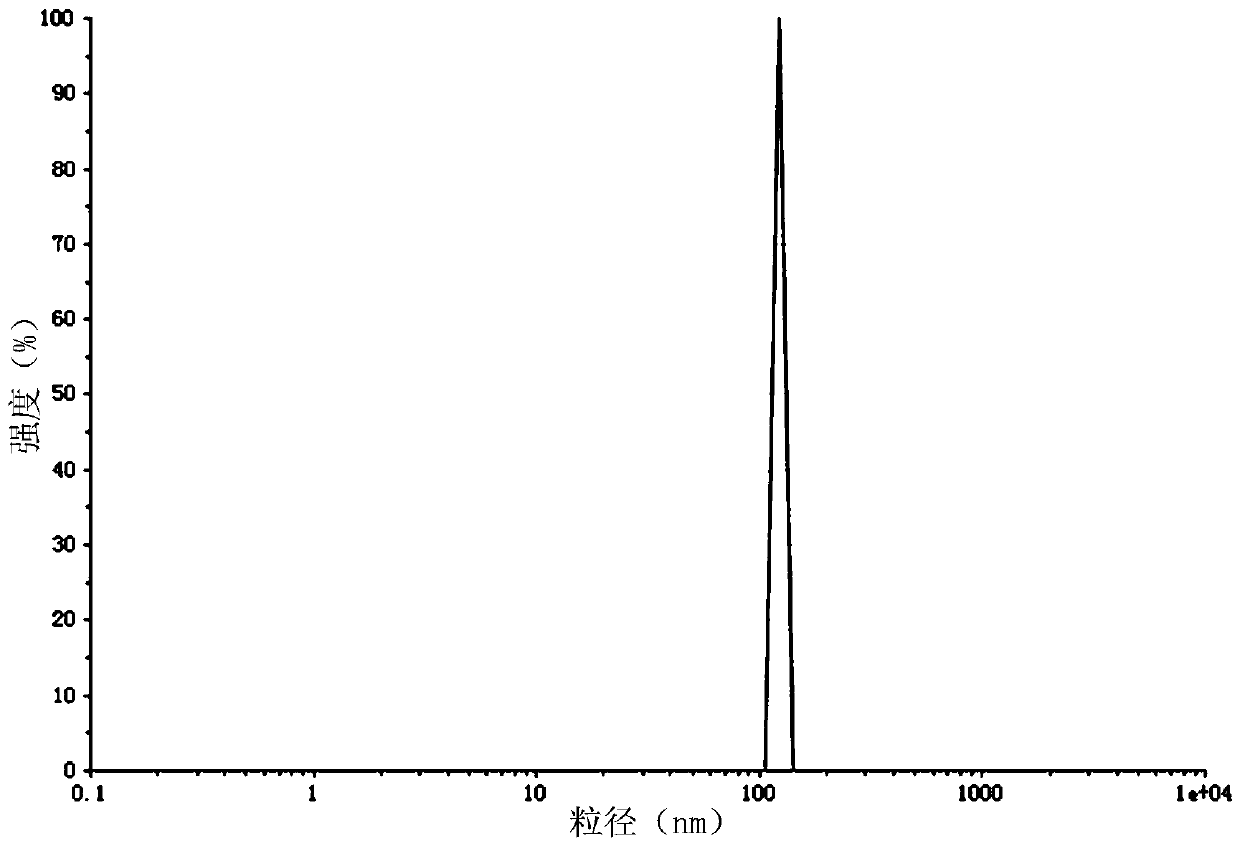

[0025] Weigh 5.3 g Na 2 CO 3 The powder was dissolved in 25mL double distilled water, in Na 2 CO 3 EDTA (1%, w / w-Na 2 CO 3 ) and Na 2 HPO 4 (1%, w / w-Na 2 CO 3 ), reacted for 10 minutes; then stirred with PEG 4000 (1%, w / w-CaCl 2 ) of 5.55g CaCl 2 Solution 25mL was slowly added dropwise to the above Na 2 CO 3 In the mixed solution, the rate of addition is 1 drop / second. After fully reacting for 30 minutes, add sodium polyacrylate solution (1%, w / w-CaCl 2 ) 50mL, intermittent ultrasonication for 10 minutes, that is, every ultrasonic 5 seconds, intermittent 5 seconds; stand at room temperature for 72 hours, centrifuge to collect the precipitate, wash three times with double distilled water, wash three times with absolute ethanol; dry the precipitate in an oven, then Obtain nanometer calcium carbonate powder. The obtained sample is detected with a particle size analyzer for particle size distribution and Zeta potential, and the average potential is -28.8mV, such as ...

Embodiment 3

[0031] Get the nano-calcium carbonate prepared by embodiment 2 and the common calcium carbonate prepared by comparative example 2 to carry out the in vitro lead removal experiment, and the specific implementation process is as follows:

[0032] Prepare simulated duodenal fluid: take 6.8g of potassium dihydrogen phosphate, add 500ml of water to dissolve, adjust the pH value to 6.8 with 0.4% sodium hydroxide solution; take another 10g of pancreatin, add appropriate amount of water to dissolve; mix the two liquids, Add water to dilute to 1000ml.

[0033] Precisely weigh and quantify lead acetate solids and add them to 100ml simulated intestinal fluid respectively, so that the final concentrations of lead ions are 0, 150, 250, 500 μg / L respectively.

[0034] Accurately weigh 40 mg of the nano-calcium carbonate powder prepared in Example 2 and the common calcium carbonate powder prepared in Comparative Example 2 and add respectively to the above-mentioned simulated intestinal fluid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com