Lithium ion battery waste cathode piece recycling method

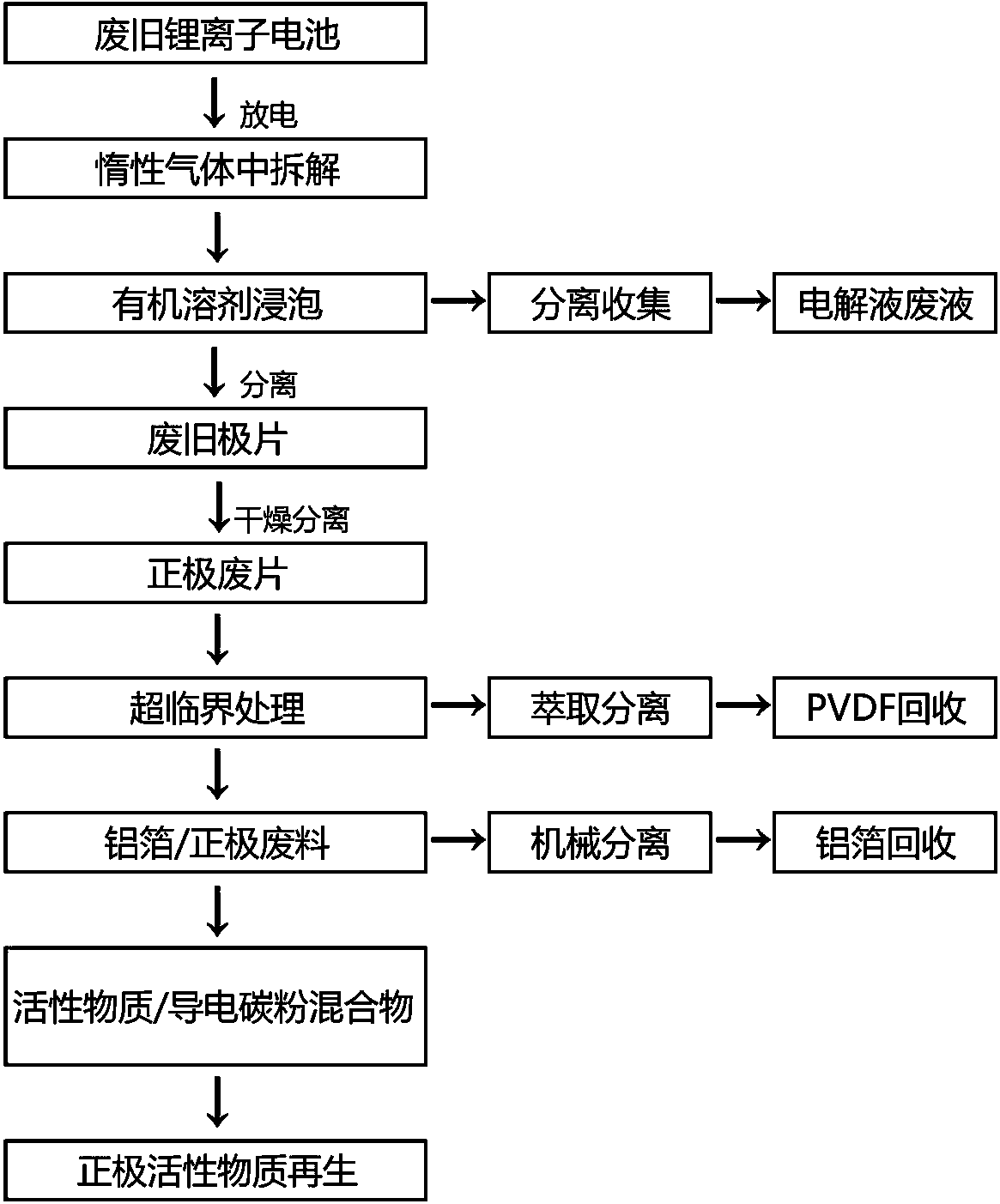

A technology for a lithium ion battery and a recycling method, which is applied in the field of supercritical fluid extraction method for recycling waste cathodes of waste lithium ion batteries, can solve the problems of consuming large chemicals, high processing equipment, and difficulty in realizing large-scale processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Deep discharge the 18650 lithium cobalt oxide battery to below 2.4 V, then disassemble the battery case in a nitrogen glove box, take out the pole piece and soak it in propylene carbonate solvent for 12 hours, so that the electrolyte and lithium salt in the pole piece can be fully diffused into the solvent; then take out the pole piece and dry it under vacuum at 100°C for 12 hours, disassemble the positive electrode waste piece without electrolyte, transfer it to a supercritical extraction device, use DME as the supercritical solvent, and set the temperature to 100°C, the pressure was set at 5 MPa, and after 4 hours of supercritical extraction, the PVDF in the positive electrode waste was completely extracted, and then the PVDF was collected in the separator of the supercritical equipment, and the remaining positive electrode waste and aluminum foil were peeled off each other; The separator separates aluminum foil and positive electrode waste (mixture of lithium cobalt o...

Embodiment 2

[0021] Deeply discharge the ternary polymer lithium battery to below 2.4 V, then disassemble the battery case in an argon glove box, take out the pole piece and soak it in diethyl carbonate solvent for 24 hours to make the electrolyte and lithium salt in the pole piece Fully diffuse into the solvent; then take out the pole piece and dry it in vacuum at 150°C for 12 hours, disassemble the positive electrode waste piece without electrolyte, transfer it to a supercritical extraction equipment, use acetone as the supercritical solvent, and set the temperature to Set at 230°C, set the pressure at 7 MPa, and after supercritical treatment for 6 hours, the PVDF in the positive electrode waste was completely extracted, and then PVDF was collected in the separator, and the remaining positive electrode waste and aluminum foil were peeled off each other; Separate the aluminum foil and positive electrode waste (ternary material and conductive carbon powder mixture).

Embodiment 3

[0023] Deep discharge the soft-pack lithium iron phosphate battery to below 2.0 V, then disassemble the battery case in an argon glove box, take out the pole piece and soak it in dimethyl carbonate solvent for 24 hours, so that the electrolyte and lithium salt in the pole piece Fully diffuse into the solvent; then take out the pole piece and dry it in vacuum at 80°C for 12 hours, disassemble the positive electrode waste piece without electrolyte, transfer it to a supercritical extraction equipment, use ethanol as the supercritical solvent, and set the temperature to Set the temperature at 210°C and the pressure at 20 MPa. After 6 hours of supercritical treatment, the PVDF in the positive electrode waste is completely extracted, and then the PVDF is collected in the separator, and the remaining positive electrode waste and aluminum foil are peeled off each other; Separate aluminum foil and positive electrode waste (lithium iron phosphate material and conductive carbon powder mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com