Persulfate enhanced ball-milling treatment method of chemical waste

A persulfate and chemical technology, which is applied in the field of persulfate enhanced ball milling to treat chemical waste, can solve the problems of large material volume and long reaction time, and achieve the effect of short reaction time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

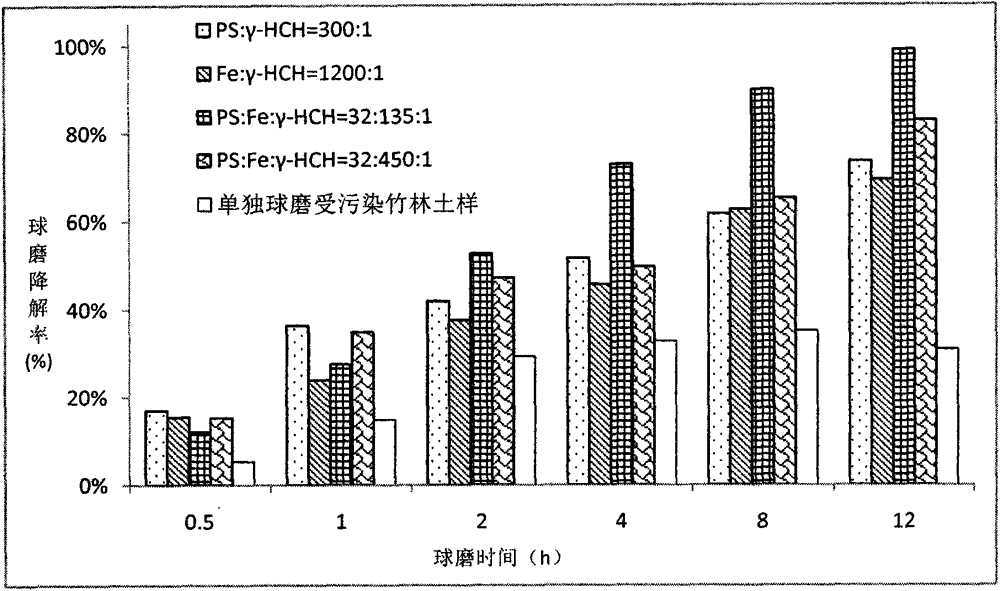

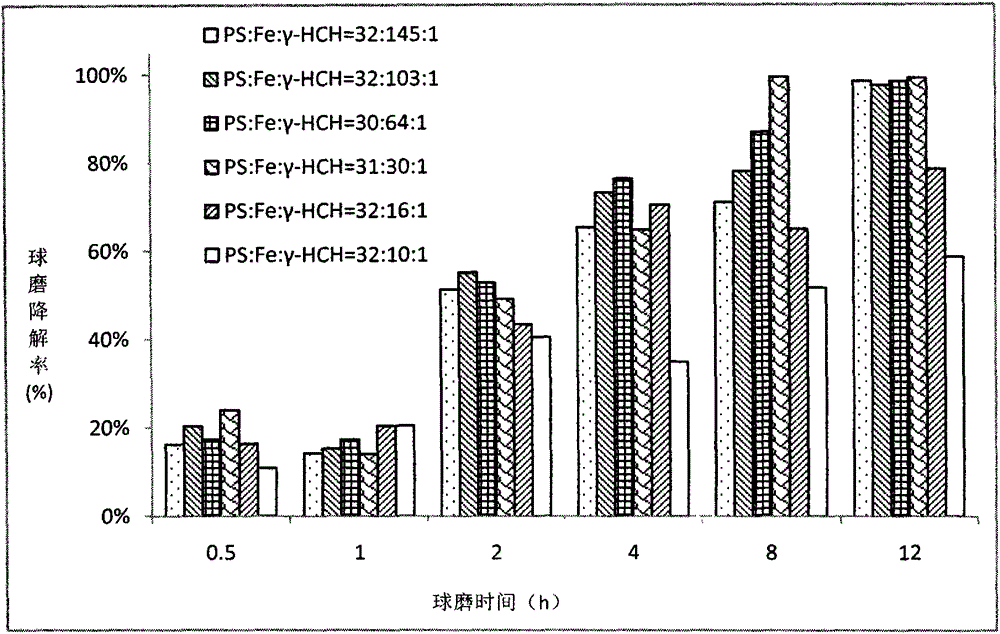

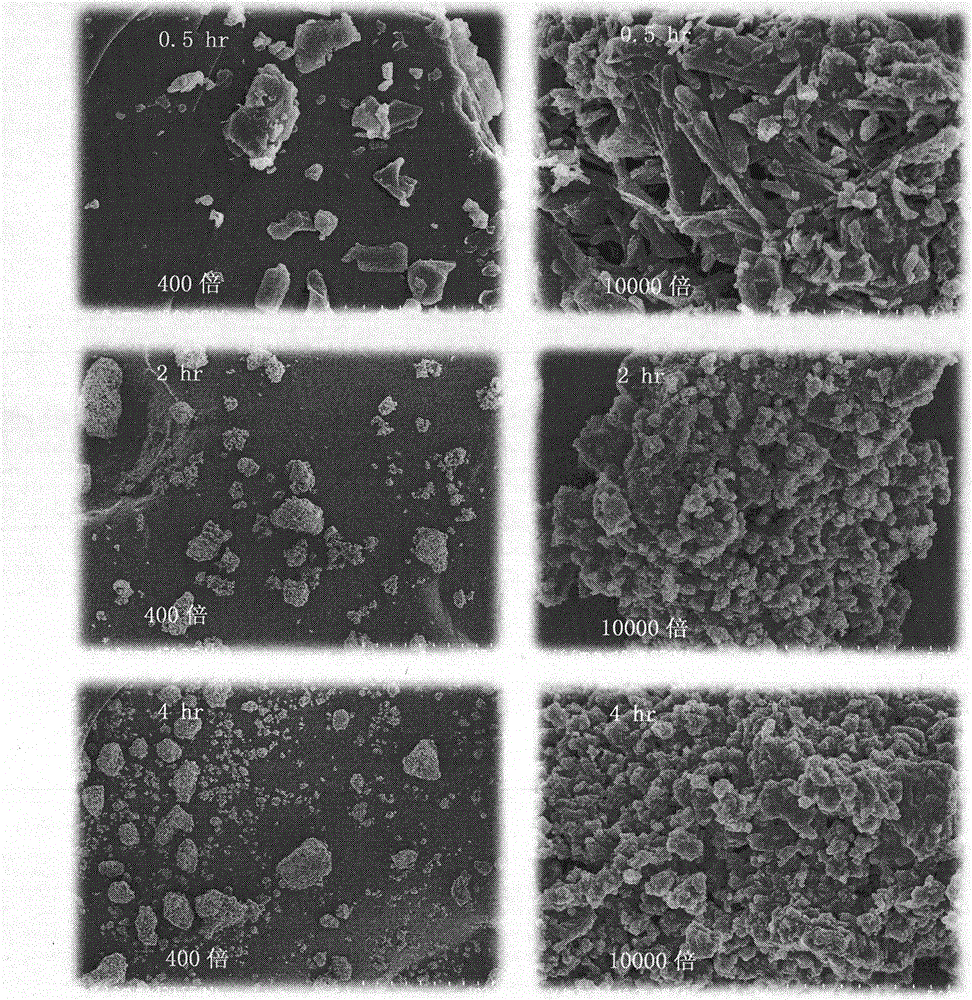

[0032] Sodium persulfate enhanced ball milling method for treating soil contaminated by lindane

[0033] 1. Preparation of contaminated soil

[0034] Soil: Take 1kg of soil 10-30cm below the surface of a bamboo forest in a certain campus, the soil is brown, loamy sandy soil structure (sand 82%; silt 10%; clay 8%), pH=7.3, organic matter content 0.6%

[0035] Soil standard addition (79.97mg / kg): After adding γ-HCH standard solution (solvent is acetone and dichloromethane mixed solution, volume ratio is 1:1) to the ground and sieved (70 mesh) soil, put it in the fume hood Volatile solvent inside, stir evenly with a glass rod for 5 minutes every morning and evening, for seven days.

[0036] 2. Ball milling conditions

[0037] The ball mill used was produced by the Instrument Factory of Nanjing University, the model is QM-QX2, and the ball mill jar and balls are made of stainless steel.

[0038] Ball loading: add 15 Φ8mm balls and 45 Φ5mm balls to four 100mL ball milling jars r...

specific Embodiment example 2

[0047] Sodium persulfate intensified ball milling method for drug compound sulfamethoxazole

[0048] 1. Ball milling conditions

[0049] The ball mill used was produced by the Instrument Factory of Nanjing University, the model is QM-QX2, and the ball mill jar and balls are made of zirconia.

[0050] Ball loading: Add 30 Φ8mm balls to four 100mL ball milling jars, and ensure that the quality difference in the symmetrical sampling jars is not higher than 0.01g.

[0051] Feeding: compound sulfamethoxazole tablet 0.5g (wherein containing sulfamethoxazole 0.4g, trimethoprim 0.08g), total mass is 5g of sodium persulfate and co-grinding reagent (reducing iron oxide powder, calcium oxide, hydrogen sodium oxide)

[0052] Nitrogen blowing: After blowing the ball mill tank with the materials under the slow nitrogen flow for about 1min, seal the ball mill.

[0053] Speed: The rotation speed is set to 500rpm, the revolution speed is set to 250rpm, and the revolution direction is revers...

specific Embodiment example 3

[0071] Sodium persulfate intensified ball milling method for treating tetrabromobisphenol A

[0072] 1. Ball milling conditions

[0073] The ball mill used was produced by the Instrument Factory of Nanjing University, the model is QM-QX2, and the ball mill jar and balls are made of zirconia.

[0074] Ball loading: Add 30 Φ8mm balls to four 100mL ball milling jars, and ensure that the quality difference in the symmetrical sampling jars is not higher than 0.01g.

[0075] Feed: Tetrabromobisphenol A 0.5g, sodium persulfate and co-grinding reagent (reduced iron oxide powder, calcium oxide, sodium hydroxide) with a total mass of 5g

[0076] Nitrogen blowing: After blowing the ball mill tank with the materials under the slow nitrogen flow for about 1min, seal the ball mill.

[0077] Speed: The rotation speed is set to 500rpm, the revolution speed is set to 250rpm, and the revolution direction is reversed alternately every 30min. Grind until the specified time and sample for testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com