Resource treatment method for fine terephthalic acid waste residue

A technology of purified terephthalic acid and its treatment method, which is applied in the field of resourceful treatment of purified terephthalic acid waste residue, can solve problems such as environmental pollution, waste of valuable resources, waste of resources, and energy, and meet the requirements of circular economy and environmental protection required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

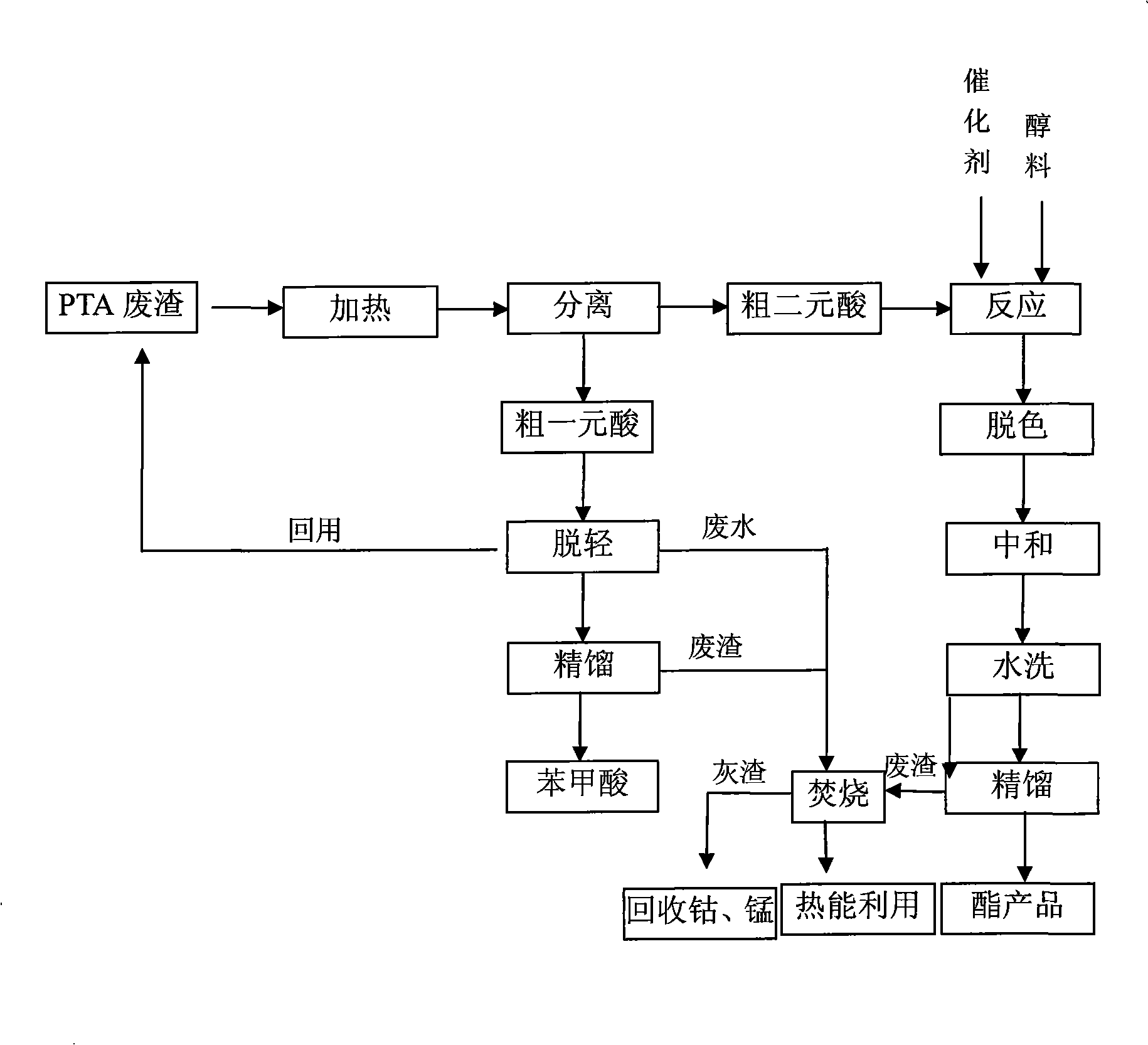

[0019] Put the PTA waste residue into the kettle, heat to 80°C, and stir at the same time to dissolve the benzoic acid, and use a centrifuge to centrifuge while it is hot. The obtained filtrate is crude monobasic acid (the quality is 43% of the original residue), and the filter residue is crude dibasic acid (the quality is 56% of the original residue).

[0020] Put the crude monobasic acid into the kettle, adjust the temperature to 60-70°C, evaporate and condense the light components into waste water; raise the temperature of the remaining liquid after removing the light components to 200-220°C, control the pressure at about 0.8Mpa, and carry out Rectification, worth benzoic acid with a purity of 98.5%.

[0021] The thick dibasic acid (acid value 568.46gKOH / kg, content is 80%) residue is placed in the reaction kettle, add ethanol (add 920 grams of ethanol in every kilogram of crude dibasic acid) and concentrated sulfuric acid (the addition amount is crude dibasic acid 4% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com