Method for removing organic oxygenated chemicals in water

A technology of organic compounds and compounds, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as impracticality, loss of market competitiveness, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Take 75 grams of Fischer-Tropsch process wastewater, whose chemical oxygen demand (COD) is 219,793, and adopt the method of the present invention to remove organic oxygen-containing compounds therein.

[0059] In this embodiment, the method of the present invention adopts the following process conditions: reaction temperature: 220-310° C.; reaction pressure: 70-140 atmospheres; reactor: laboratory-scale batch reactor; reaction time: 120 minutes.

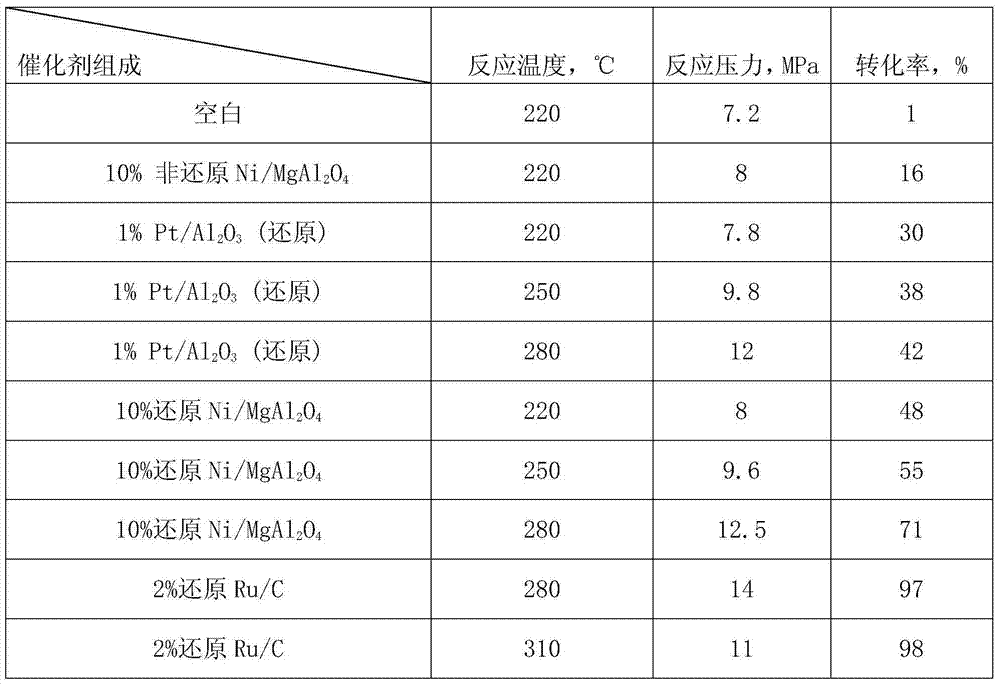

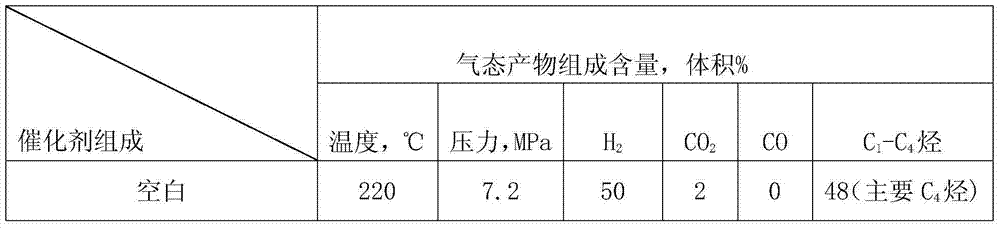

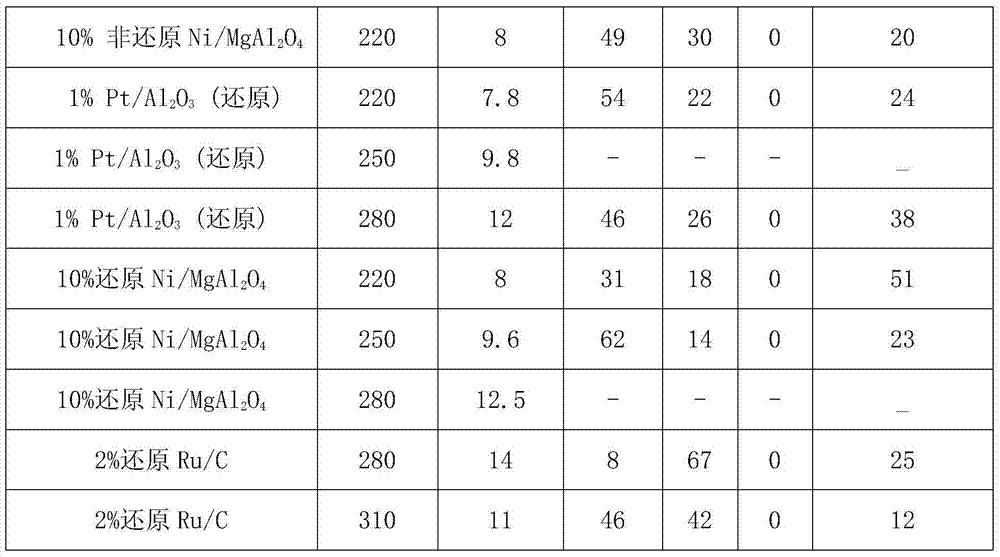

[0060] In this example, the catalysts used are shown in Table 1 and Table 2, and the catalysts were heated by H at 400°C 2 reduction.

[0061] First, place the catalyst in the Fischer-Tropsch process wastewater at room temperature, and use nitrogen to pressurize to 1-40 atmospheres, after that, heat the reactor to 220°C or 310°C, the residence time of the Fischer-Tropsch process wastewater in the reactor After cooling the reactor for 120 minutes, the gas phase product and the liquid phase product were taken out and analyzed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com