Incineration boiler for saline waste liquid

A salt-containing waste liquid and boiler technology, applied in the field of boilers, can solve the problems of abnormal system operation, corrosion of furnace lining and heat exchange surface, scaling and blockage of heating surface, etc., and achieves simple manufacturing process, safe and stable operation, and reduced waste liquid. Effects of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

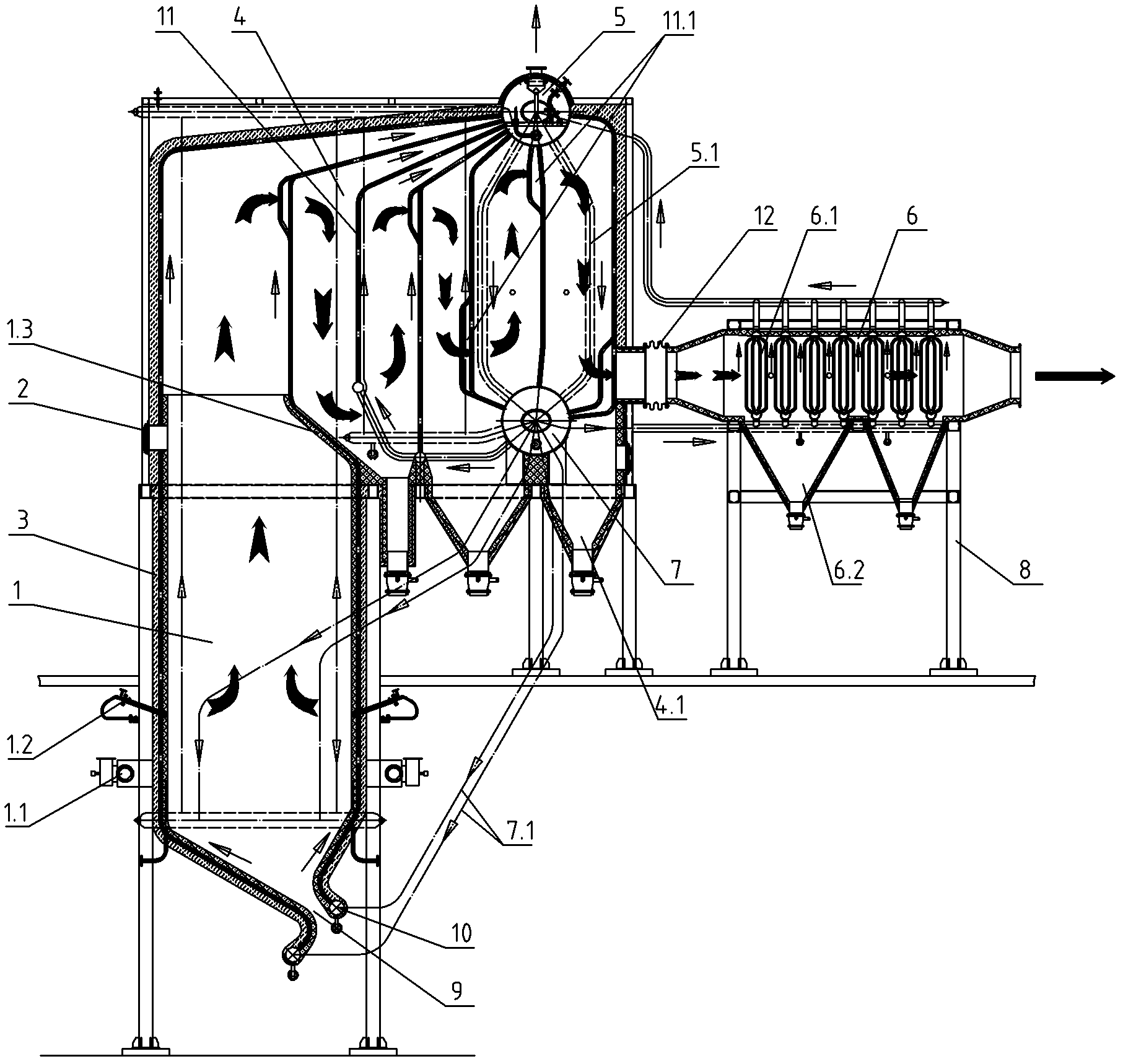

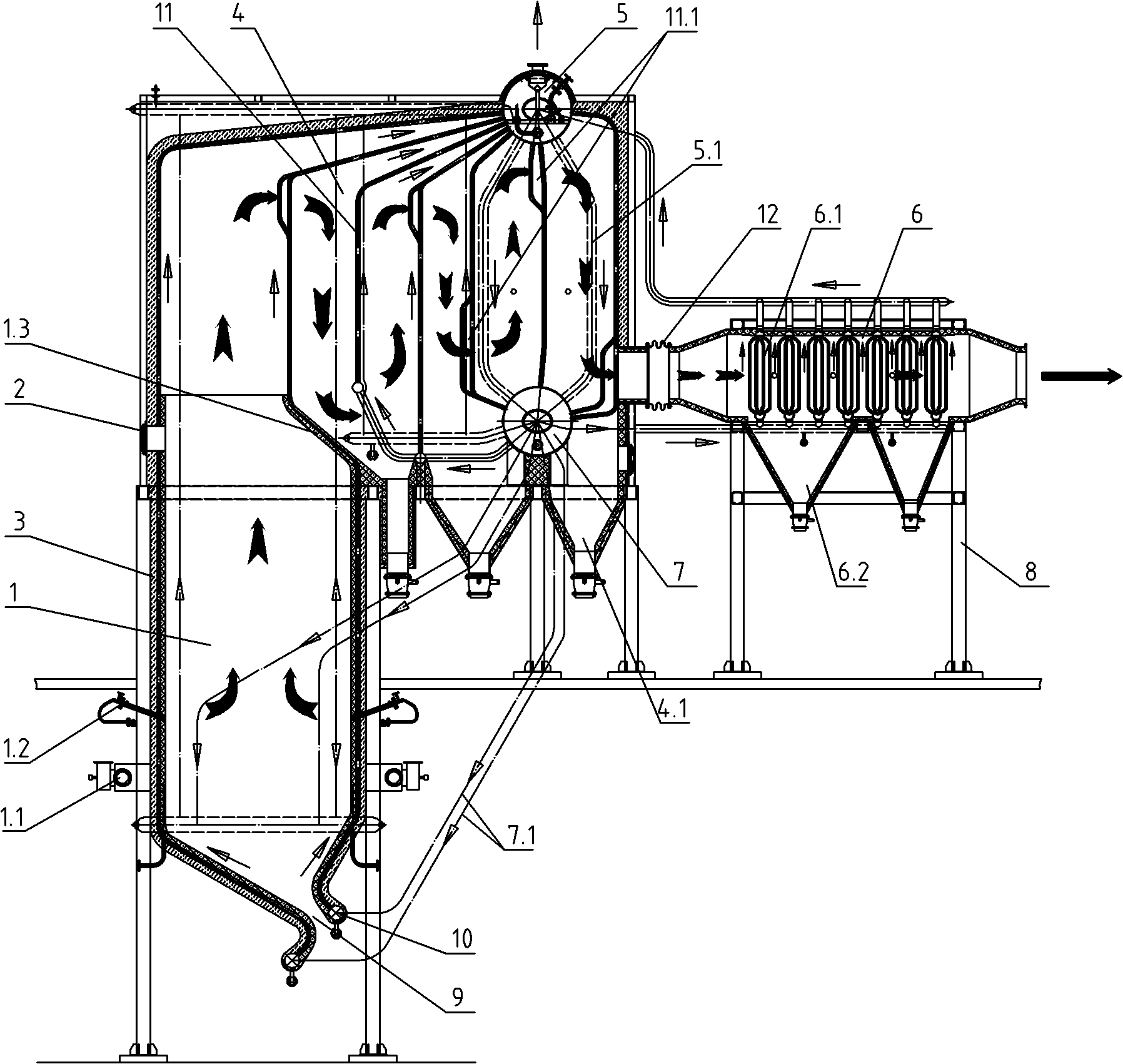

[0010] Such as figure 1 The shown a kind of saline waste liquid incineration boiler comprises a combustion chamber 1, a furnace door 2, a furnace wall 3, a cooling chamber 4, an upper drum (steam drum) 5, a flue gas outlet pipe 6, a lower drum 7, and The steel frame 8 used to support and fix each part, the lower side wall of the combustion chamber 1 is respectively provided with a burner 1.1 for injecting auxiliary gas or liquid fuel into the combustion chamber 1 for combustion and a burner 1.1 for injecting salty waste liquid into the combustion chamber The waste liquid spray gun 1.2 in 1, and the waste liquid spray gun 1.2 is located above the burner 1.1; the combustion chamber 1 is made of chromium corundum refractory concrete that is resistant to sodium salt corrosion, and the side wall of the combustion chamber 1 extends downward, and the downward extending The side wall is in the shape of a closed mouth so as to form a molten sodium salt lye that is convenient for the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com