Procyanidins oligomer and its preparing method and use

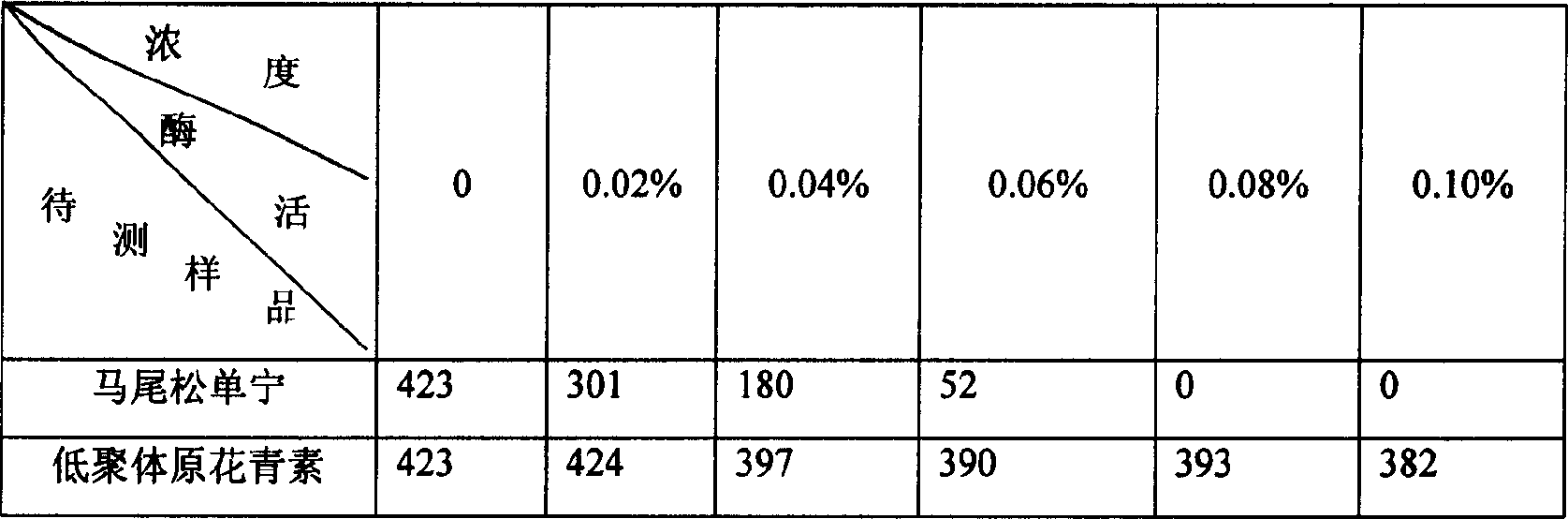

A proanthocyanidin, oligomer technology, applied in the application, animal feed, animal feed and other directions, can solve problems such as reducing enzyme activity, achieve the effect of disappearing taste astringency, reducing pollution, strong antioxidant function and antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Extraction and decomposition of fresh Pinus massoniana pine needle tannins.

[0027]Chop 10kg of fresh pine needles into small pieces, add 50kg to 60kg of water, and heat at 90-100°C for 30 minutes. Remove the residue by filtration, continue heating and concentrating the supernatant to 5 kg of the original volume, add 20 kg of 27.3% hydrogen peroxide, adjust the pH to 7 with sodium hydroxide, and heat to 50° C. for 30 minutes to degrade. After the degradation is completed, continue heating and stirring to volatilize clean hydrogen peroxide, concentrate to 3 kg, and obtain golden or brown product oligomer proanthocyanidins.

Embodiment 2

[0028] Example 2: Decomposition of larch extract

[0029] Add 1 kg of larch extract to 1 kg of water, then add 2 kg of 50% hydrogen peroxide, adjust the pH to 7 with sodium hydroxide solution, and heat to 30°C for 30 minutes to degrade. After the degradation is completed, continue heating and stirring, and add 1 to 2 kg of water to supplement, volatilize clean hydrogen peroxide, concentrate to 2 kg, and obtain golden or brown product oligomer proanthocyanidins.

Embodiment 3

[0030] Example 3: Black Wattle Bark Tannin

[0031] Add 1 kg of black wattle bark tannin to 1 kg of water, then add 2 kg of 50% hydrogen peroxide, adjust the pH to 6 with sodium hydroxide, and heat to 40°C for 30 minutes to degrade. After the degradation is completed, continue heating and stirring, and add 1-2 kg of water to supplement, volatilize clean hydrogen peroxide, concentrate to 2 kg, and obtain golden or brown product oligomer proanthocyanidins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com