Clamp assembly for testing adhesive force between tubular propellant and chemical fixing adhesive tape

A technology for testing fixtures and propellants, which is used in measuring devices, instruments, and mechanical devices, etc., can solve problems such as difficult tooling fixtures, personal casualties, and high propellant burning rates, so as to increase mechanical properties and solve safety problems. , the effect of reducing friction sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

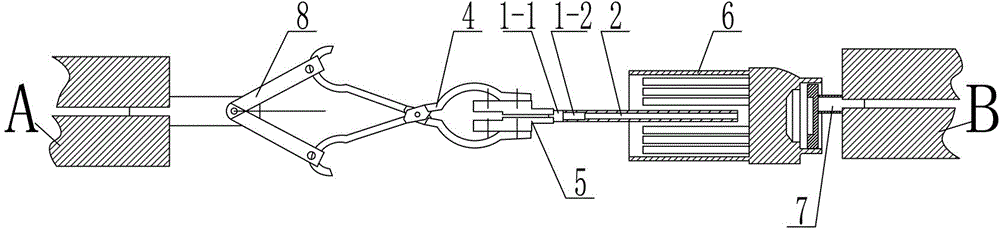

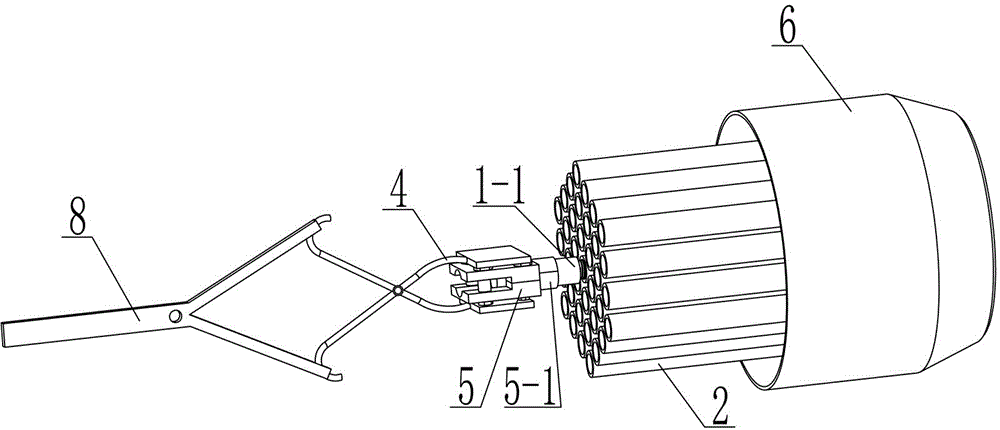

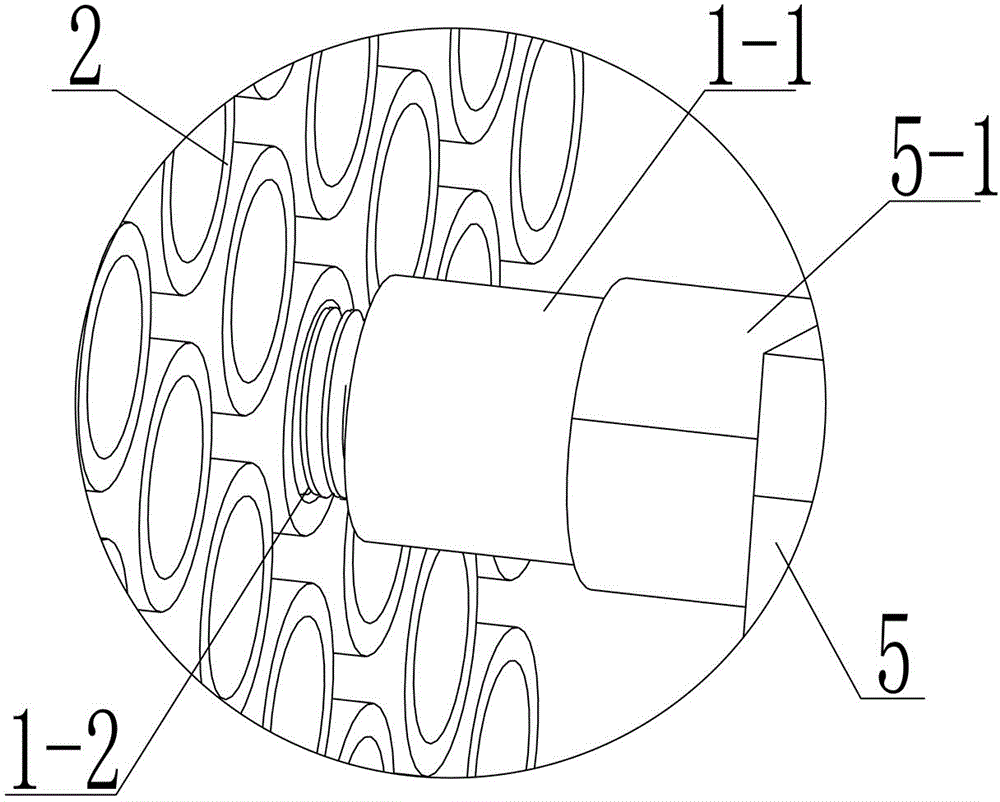

[0014] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes a copper rod, a connecting clamp 5, a tension frame 8, a clamp pliers 4 and an inner shell 6 with a medicine tube 2; the copper rod is clamped by the connecting rod 1-2 Composed of a rod 1-1, the cross section of the connecting rod 1-2 and the clamping rod 1-1 is circular, the connecting rod 1-2 is provided with threads, and the connecting rod 1-2 and the medicine tube 2 connection, the axis line of the connecting rod 1-2 and the clamping rod 1-1 coincides and the diameter of the connecting rod 1-2 is smaller than the diameter of the clamping rod 1-1, and the diameter of the clamping rod 1-1 is the same as the outer diameter of the drug tube The same; the rear end of the connecting clip 5 is provided with a semicircular pipe 5-1, the semicircular pipe 5-1 is provided with threads, the semicircular pipe 5-1 is connected with the clamping rod 1-1, and the upper end of the connecting clip 5 There are thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com