Metallurgical coke with high strength at high temperature

A high-heat, high-strength technology, used in the petroleum industry, solid fuels, fuels, etc., can solve the problems of high coke ash content, waste of heat energy and water resources, and high coke powder ash content, so as to save coal for coking. , Simplified process, the effect of high thermal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation mode of coke powder washing is: using a shaker sorter or a spiral sorter to wash coke powder, and then carry out water separation and initial drying to the washed coke powder after washing. The ash content of the washed fine coke powder is less than 12%, and the moisture content after initial drying is less than 5%. The specifications of the shaker separator or spiral separator can be designed and processed by entrusting mineral processing machinery factory or coal preparation machinery factory according to the output demand of the coke production plant.

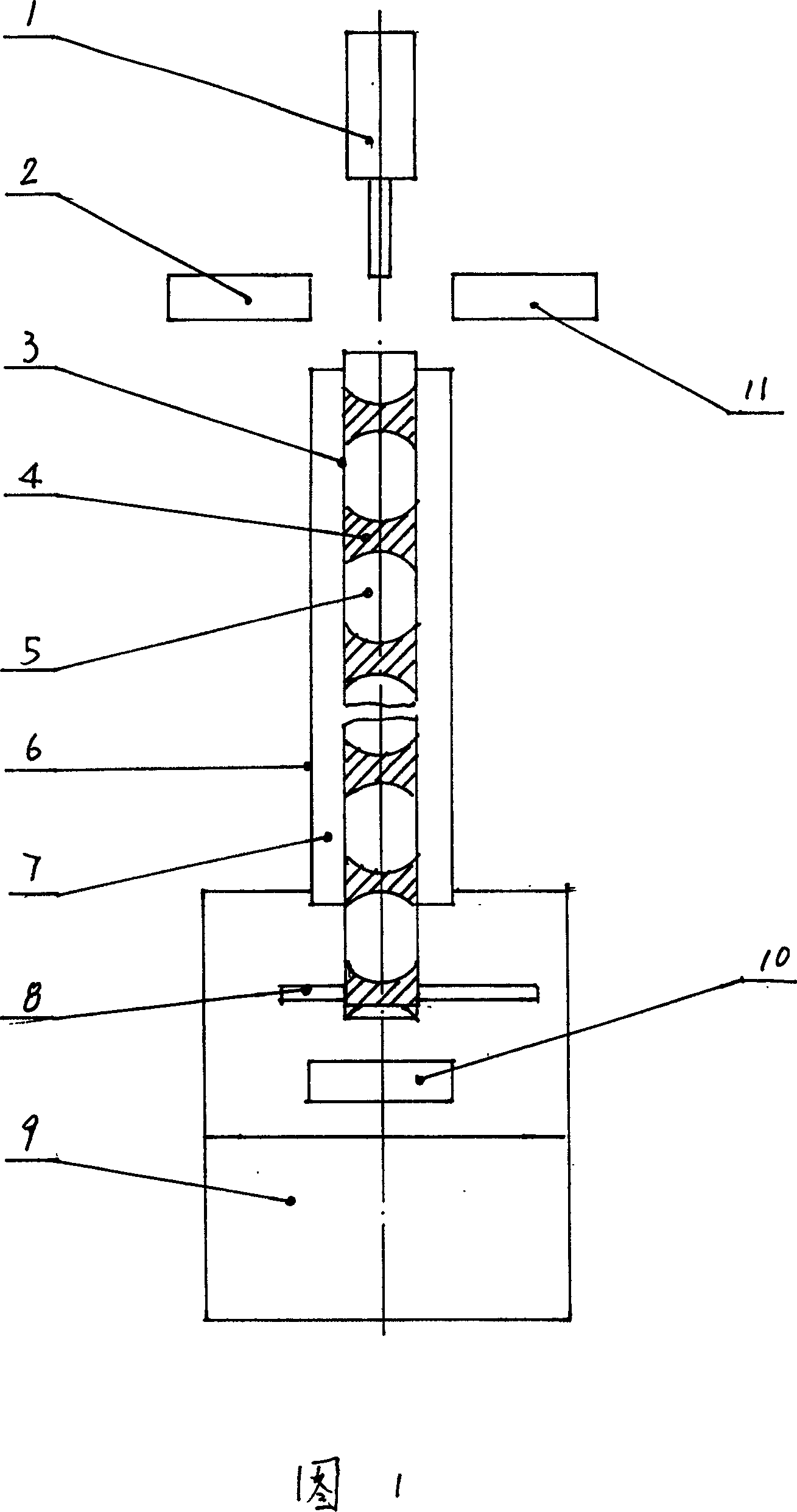

[0014] The vibratory continuous molding method of coke is: in order to improve the thermal strength of the coke and realize high-efficiency continuous vibratory molding, the present invention specially made a "multi-station tube vibration molding machine" to realize "upper feeding, Vibration continuous molding method. The production process is explained with reference to the accompanying drawings: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com