Method for coating CL-20 explosive with plasticized Estane5703

A CL-20, explosive technology, used in explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

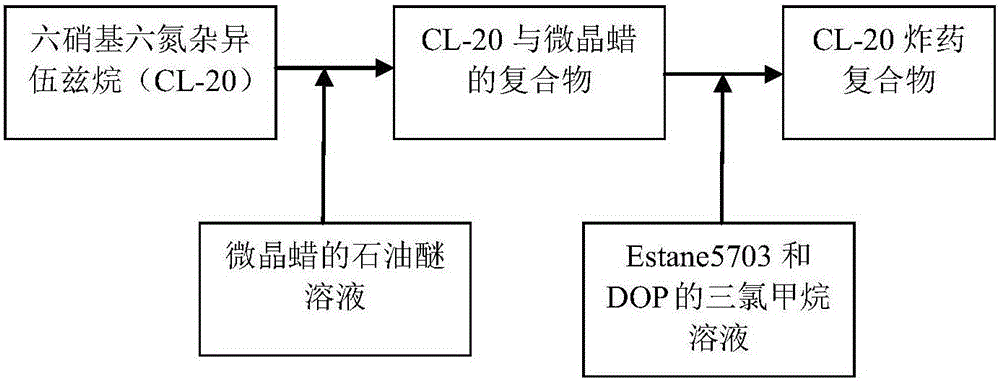

Method used

Image

Examples

Embodiment 1

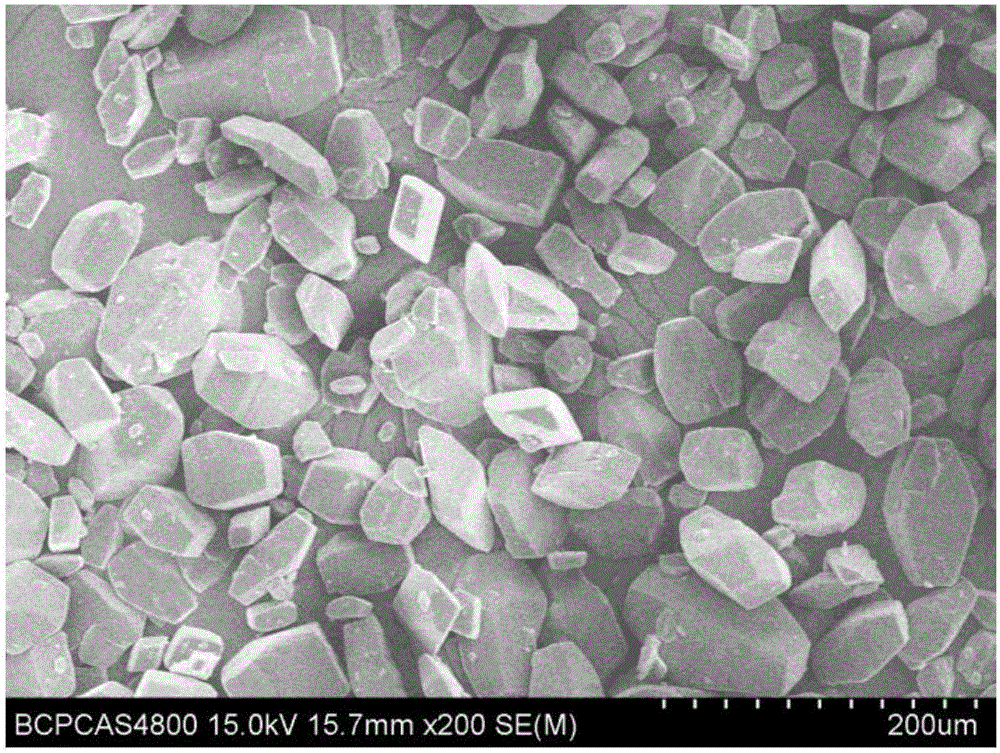

[0030] (1) Set the temperature of the constant temperature water bath to 65°C and start the water circulation. Weigh 120g of pure water into the reactor, turn on the stirring motor at a stirring speed of 450r / min, add 100g of CL-20 into the reactor and stir, so that the CL-20 crystals are evenly dispersed, and the explosive mixture is obtained.

[0031] (2) Dissolve 2 g of No. 80 microcrystalline wax in 18 g of analytically pure petroleum ether to obtain a 10% mass concentration of microcrystalline wax petroleum ether solution for use.

[0032] 1.6 g of Estane5703 and 0.4 g of DOP were dissolved in 38 g of analytically pure chloroform to obtain a 5% mass concentration of chloroform solution containing Estane5703 and DOP for use.

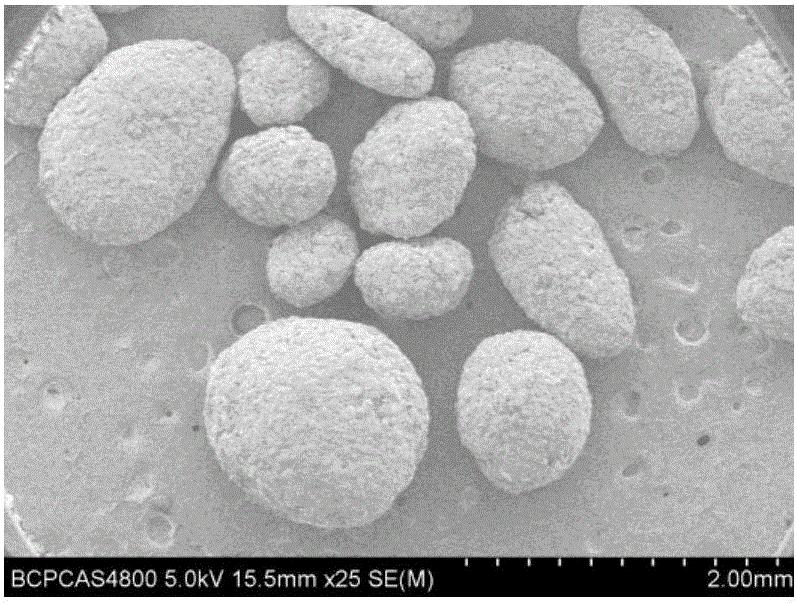

[0033] (3) Raise the temperature of the explosive mixture to 64-66°C, turn on the vacuum pump to release air, adjust the pressure in the kettle to 0.02Mpa, and set the temperature to 3ml·s -1 Drop the petroleum ether solution of microcrystalline wax...

Embodiment 2

[0037] (1) Set the temperature of the constant temperature water bath to 65°C and start the water circulation. Weigh 120g of pure water into the reactor, turn on the stirring motor at a stirring speed of 450r / min, add 100g of CL-20 into the reactor and stir, so that the CL-20 crystals are evenly dispersed, and the explosive mixture is obtained.

[0038] (2) Dissolve 2 g of No. 80 microcrystalline wax in 18 g of analytically pure petroleum ether to obtain a 10% mass concentration of microcrystalline wax petroleum ether solution for use.

[0039] Dissolve 2 g of fluororubber 2311 (F2311) in 38 g of analytically pure ethyl acetate to obtain an ethyl acetate solution of F2311 with a mass concentration of 5%, which is ready for use.

[0040] (3) Raise the temperature of the explosive mixture to 64-66°C, turn on the vacuum pump to release air, adjust the pressure in the kettle to 0.02Mpa, and set the temperature to 3ml·s -1 Drop the petroleum ether solution of microcrystalline wax ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com