Passivation and filter equipment for aluminum fluoropolymer mechanically activated energetic material

A technology of mechanical activation and filtering device, which is applied in the direction of feeding device, chemical/physical/physicochemical process, filtration and separation, etc., to achieve the effects of difficult ignition, short suction and filtration time, and high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

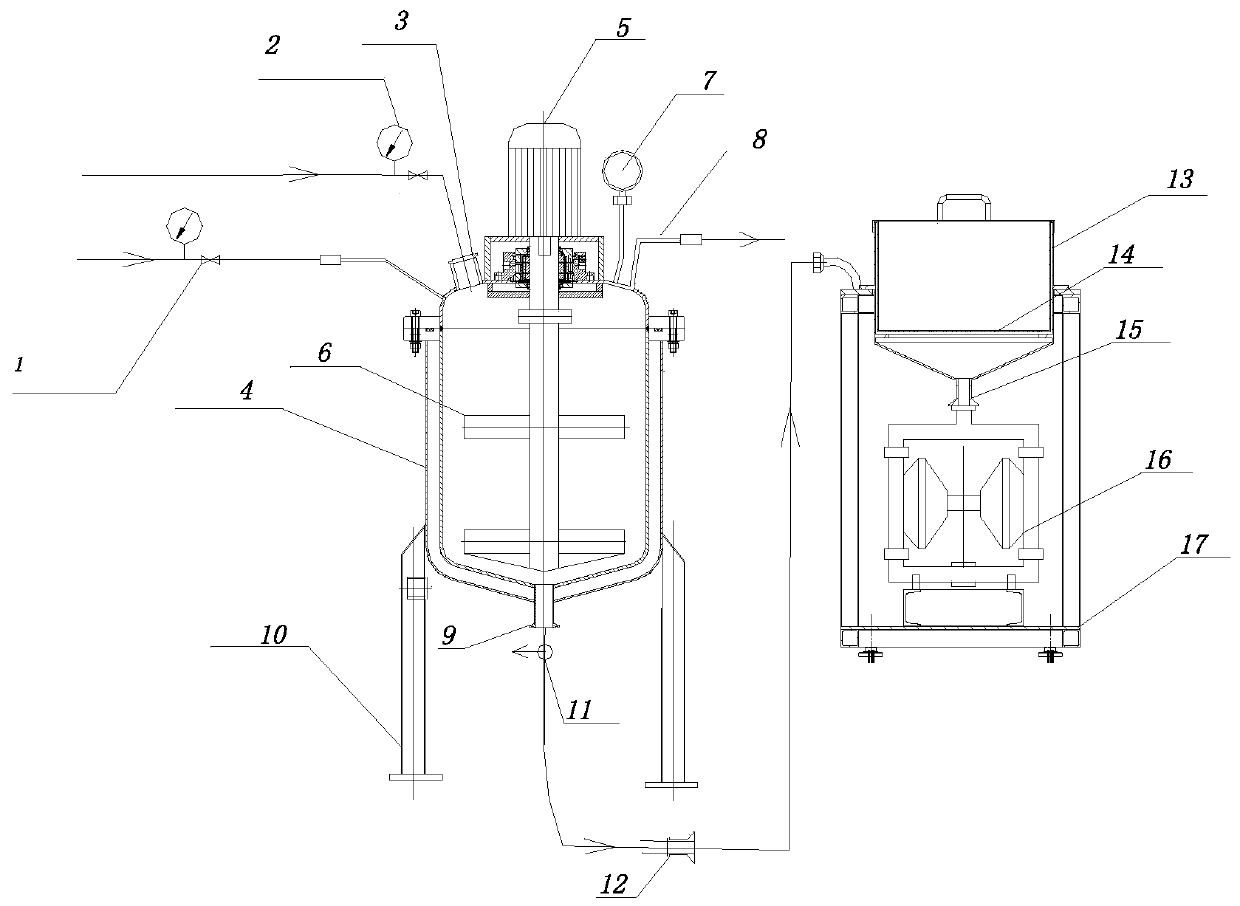

Method used

Image

Examples

Embodiment 1

[0027] Using the passivation and filtering device of the present invention, the average particle size of the aluminum powder in the raw material used to prepare the mechanically activated energetic material is 4-5 μm; the brand of the aluminum powder is FLQT-4, and the polytetrafluoroethylene specification model is CGUF201B. The aluminum powder / polytetrafluoroethylene mechanically activated energetic material is composed of aluminum powder and polytetrafluoroethylene, and the mass ratio of aluminum powder and polytetrafluoroethylene is 26.7:73.5. As a comparison, the existing technology adopts static direct discharge and natural gravity filtration technology, and the specification ratio of aluminum powder and polytetrafluoroethylene remains unchanged.

[0028] The performance test data shows that the detonation heat of the aluminum powder / polytetrafluoroethylene mechanically activated energetic material prepared by the present invention is increased by 3.58%, and the impact sen...

Embodiment 2

[0030] Using the passivation and filtering device of the present invention, the average particle size of the aluminum powder in the raw material used to prepare the mechanically activated energetic material is 26 μm; the brand of the aluminum powder is FLQT-2, and the polytetrafluoroethylene specification model is CGUF201B. The aluminum powder / polytetrafluoroethylene mechanically activated energetic material is composed of aluminum powder and polytetrafluoroethylene, and the mass ratio of aluminum powder and polytetrafluoroethylene is 26.7:73.5. The preparation steps refer to Example 1. As a comparison, the existing technology adopts static direct discharge and natural gravity filtration technology, and the specification ratio of aluminum powder and polytetrafluoroethylene remains unchanged.

[0031] The performance test data shows that the detonation heat of the aluminum powder / polytetrafluoroethylene mechanically activated energetic material prepared by the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com