Propellant and preparation method thereof

A technology of propellant and adhesive, which is used in explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of low ignition point, high impact ignition rate, environmental pollution, etc., and achieves low friction sensitivity and impact sensitivity, and low moisture absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

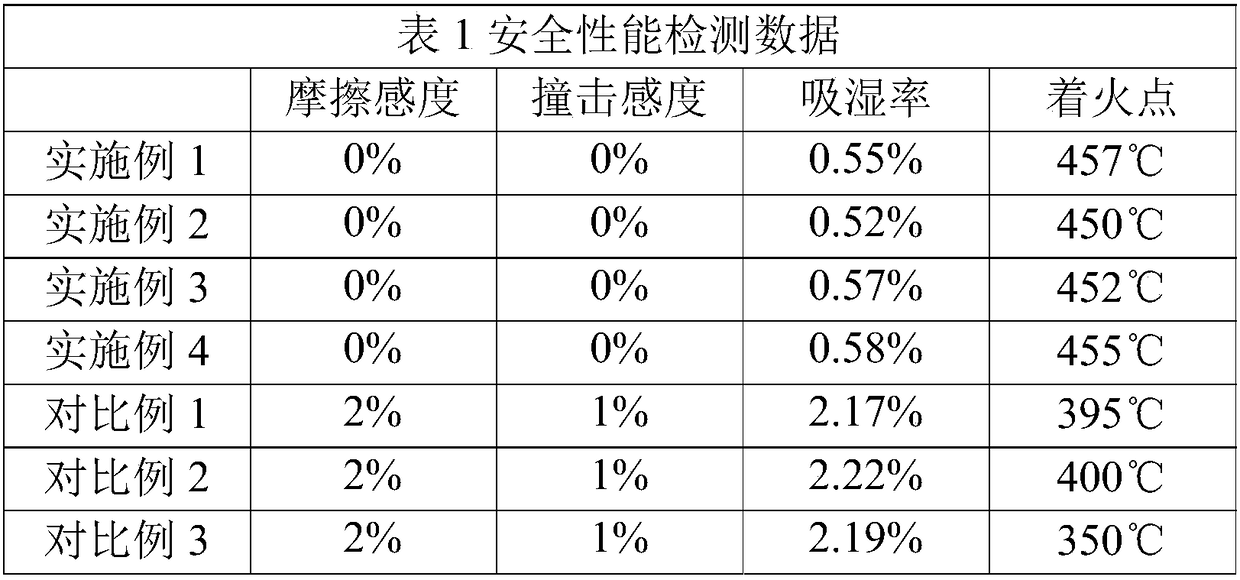

Examples

preparation example Construction

[0036] According to another aspect of the present invention, there is provided a method for preparing a propellant, which includes:

[0037] Weigh potassium permanganate, adhesives, potassium hydrogen phthalate and combustibles according to the weight of the appeal;

[0038] Screen potassium permanganate, binder, potassium hydrogen phthalate and combustible agent through 100 mesh and 200 mesh combination sets of sieves, and select potassium permanganate, binder, Potassium hydrogen phthalate and combustible agents;

[0039] Mixing medicine, mixing the potassium permanganate, the binder, and the combustible agent to prepare a mixed powder;

[0040] Wet mixing, mixing the mixed powder and the potassium hydrogen phthalate with water while stirring to prepare a mixed paste;

[0041] For granulation, the mixed ointment is put into a granulator to obtain propellant particles.

[0042] As a preferred solution, it also includes drying. The propellant particles are placed in a thermostat for dryi...

Embodiment 1

[0044] Weigh 50 parts of potassium permanganate, 8 parts of adhesive, 20 parts of potassium hydrogen phthalate and 20 parts of combustible agent according to the weight of the appeal;

[0045] Wherein, based on the total weight of the combustible agent, the amount of the magnesium powder is 10% by weight, and the amount of the charcoal powder is 90% by weight;

[0046] Screen potassium permanganate, binder, potassium hydrogen phthalate and combustible agent through 100 mesh and 200 mesh combination sets of sieves, and select potassium permanganate, binder, Potassium hydrogen phthalate and combustible agents;

[0047] Mixing medicine, mixing the potassium permanganate, the binder, and the combustible agent to prepare a mixed powder;

[0048] Wet mixing, mixing the mixed powder and the potassium hydrogen phthalate with water while stirring to prepare a mixed paste;

[0049] For granulation, the mixed ointment is put into a granulator to obtain propellant particles.

[0050] Drying, placin...

Embodiment 2

[0052] Weigh 30 parts of potassium permanganate, 20 parts of adhesive, 10 parts of potassium hydrogen phthalate and 40 parts of combustible agent according to the weight of the appeal;

[0053] Wherein, based on the total weight of the combustible agent, the amount of the magnesium powder is 5% by weight, and the amount of the charcoal powder is 95% by weight;

[0054] Screen potassium permanganate, binder, potassium hydrogen phthalate and combustible agent through 100 mesh and 200 mesh combination sets of sieves, and select potassium permanganate, binder, Potassium hydrogen phthalate and combustible agents;

[0055] Mixing medicine, mixing the potassium permanganate, the binder, and the combustible agent to prepare a mixed powder;

[0056] Wet mixing, mixing the mixed powder and the potassium hydrogen phthalate with water while stirring to prepare a mixed paste;

[0057] For granulation, the mixed ointment is put into a granulator to obtain propellant particles.

[0058] Drying, placin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com