Testing device for measuring impact sensitivity and friction sensitivity of energetic material

A testing device and impact sensitivity technology, which is applied in the field of friction sensitivity measurement and energetic material impact sensitivity, can solve the problems of large volume and heavy weight, and achieve the effects of precise control, light weight, convenient and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

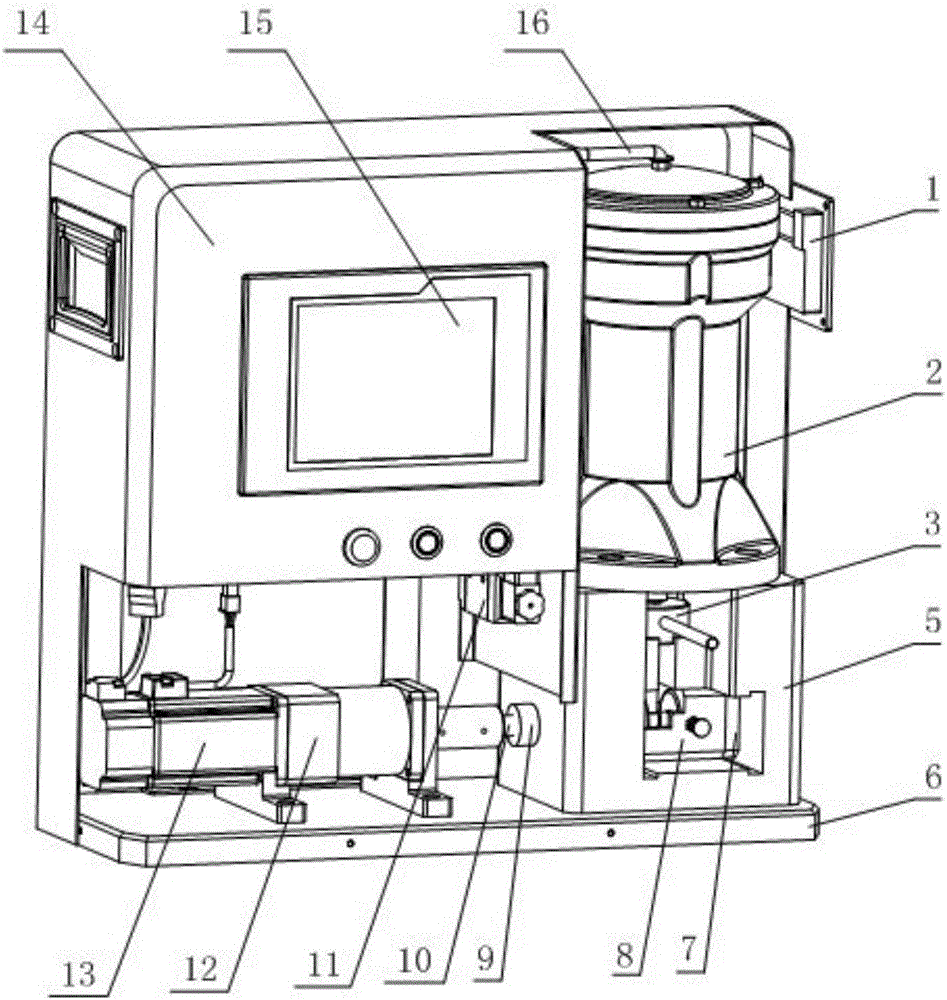

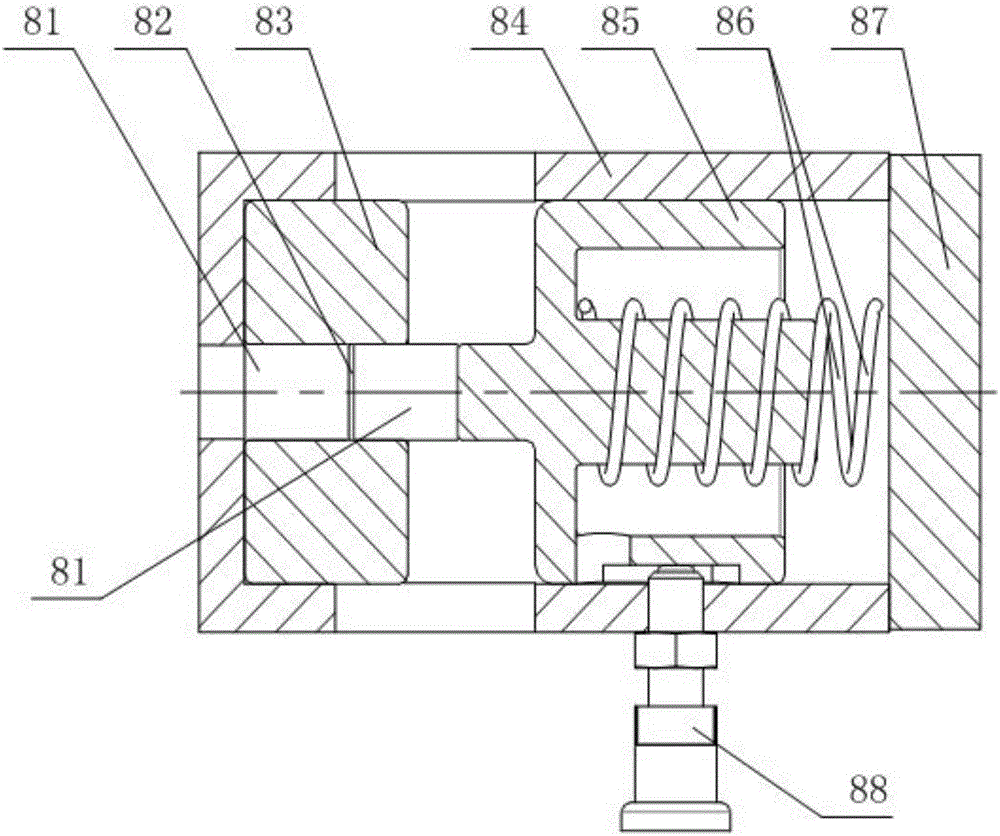

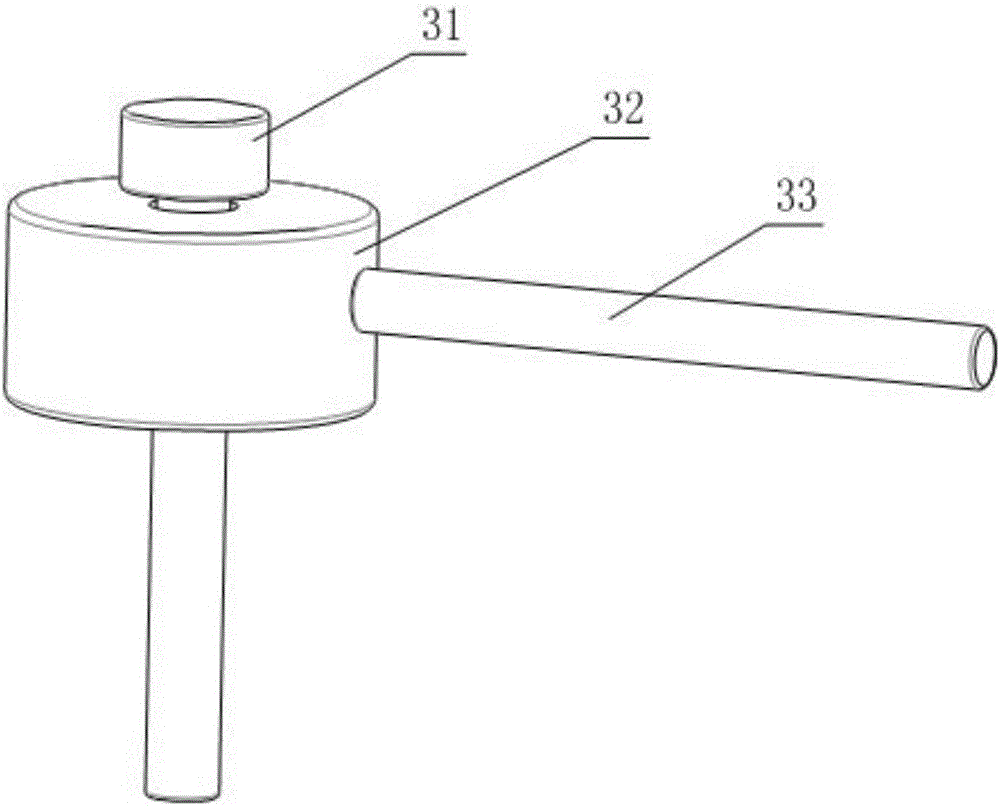

[0027] Such as Figure 1 ~ Figure 4 As shown, a test device for measuring the impact sensitivity and friction sensitivity of energetic materials includes a chassis 14, a servo motor 13, a gas pipe 16, and a pneumatic percussion hammer 2. The air outlet port of the air pipe 16 is airtightly connected with the air inlet of the pneumatic percussion hammer 2. The pneumatic percussion hammers 2 are located on the right side of the chassis 14. The pneumatic percussion hammers 2 have piston hammer bodies. The piston hammer body of the hammer 2 is provided with a sample impact test chamber, and a rod assembly 3 is movably installed in the sample impact test chamber. Striking rod 31, the bottom of the striking rod assembly 3 is horizontally placed with a strut assembly 4, the strut assembly 4 includes a strut sleeve 44, the upper end of the strut sleeve 44 is provided with a strut sleeve mounting hole, the strut sleeve 44 upper end is A stud sleeve 43 is installed in the stud sleeve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com