Explosive collision sensitivity instrument

A technology of sensitivity meter and explosives, which is applied in the field of explosives performance testing devices, can solve the problems of poor test consistency, difficult to guarantee test conditions, and low test accuracy, so as to ensure consistency, improve test accuracy and reliability, and high test accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

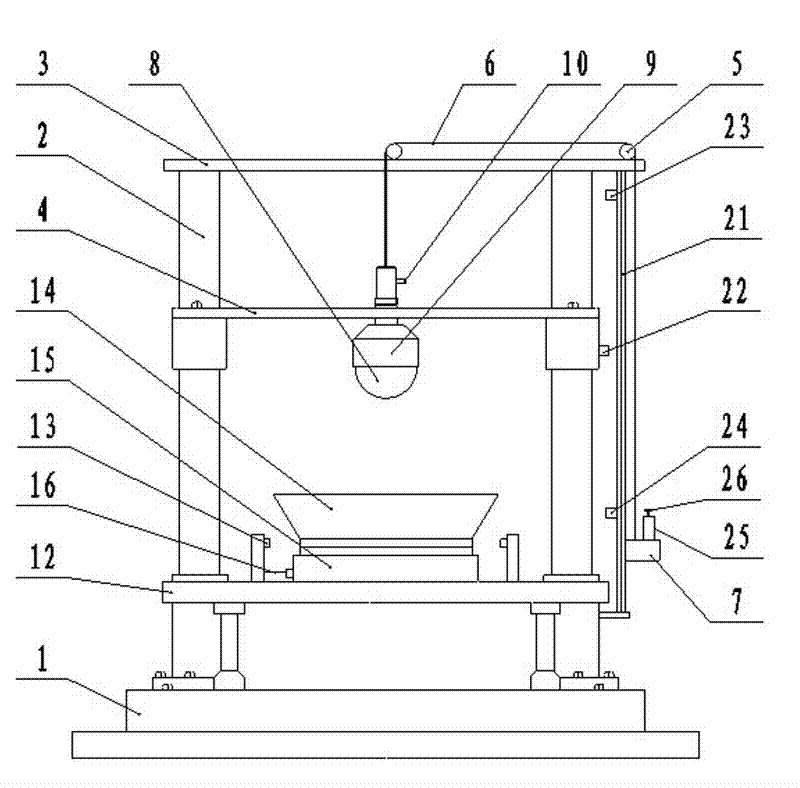

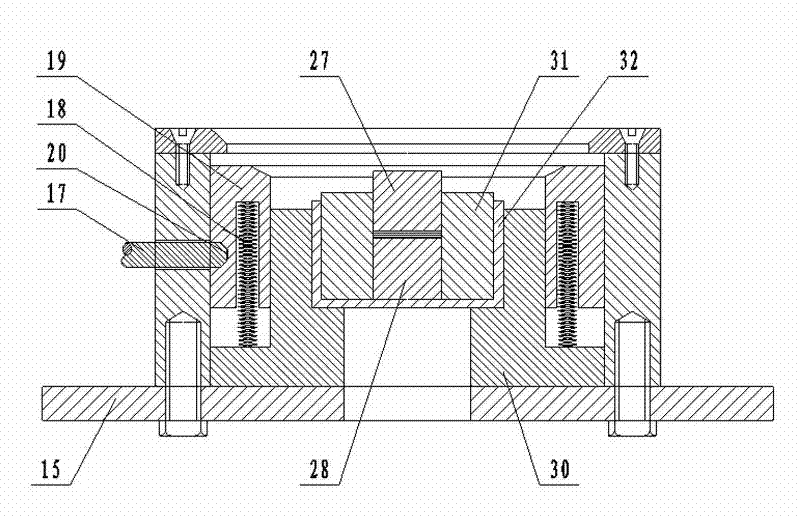

[0023]Explosive impact sensitivity instrument, including drop weight lifting and positioning mechanism, drop weight fixing and releasing mechanism, impact device mechanism, light control anti-secondary impact mechanism, and overall control mechanism;

[0024] The falling weight lifting and positioning mechanism includes a base 1, a lifting guide rail 2 vertically fixed on the upper surface of the base 1, an upper fixing plate 3 horizontally fixed on the top of the lifting guide rail 2, and a sliding connection between its end and the lifting guide rail 2. Lifting plate 4; a pulley block 5 is installed on the upper surface of the upper fixing plate 3, and a lifting rope 6 is wound on the pulley block 5; one end of the lifting rope 6 is connected with a reel 7, and the other end hangs down to fix the falling weight fixing and releasing mechanism;

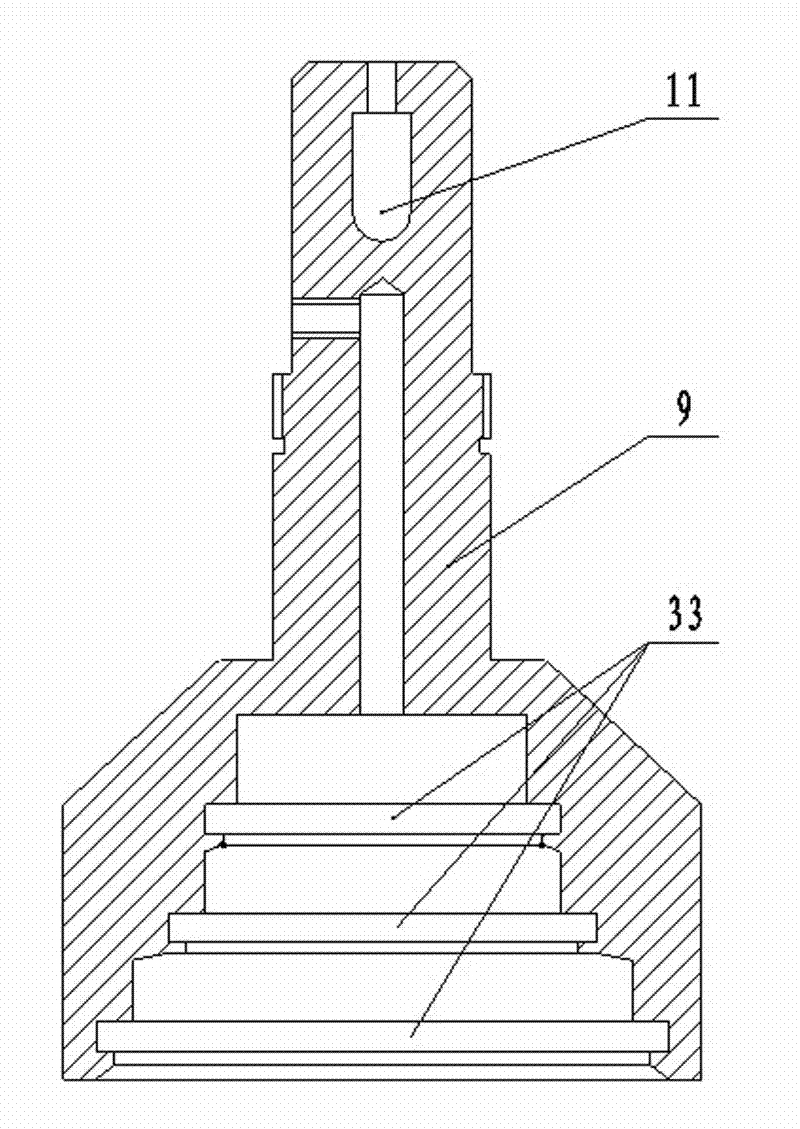

[0025] The falling weight fixing and releasing mechanism includes a dropping weight 8, a dropping weight suction cover 9, and a vacuu...

Embodiment 2

[0035] Explosive impact sensitivity instrument, including drop weight lifting and positioning mechanism, drop weight fixing and releasing mechanism, impact device mechanism, light control anti-secondary impact mechanism, and overall control mechanism;

[0036] The falling weight lifting and positioning mechanism includes a base 1, a lifting guide rail 2 vertically fixed on the upper surface of the base 1, an upper fixing plate 3 horizontally fixed on the top of the lifting guide rail 2, and a sliding connection between its end and the lifting guide rail 2. Lifting plate 4; a pulley block 5 is installed on the upper surface of the upper fixing plate 3, and a lifting rope 6 is wound on the pulley block 5; one end of the lifting rope 6 is connected with a reel 7, and the other end hangs down to fix the falling weight fixing and releasing mechanism;

[0037] The falling weight fixing and releasing mechanism includes a dropping weight 8, a dropping weight suction cover 9, and a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com