Temperature-resistance thermal insulation protecting bush

A sheath and temperature-resistant technology, which is applied in the direction of protecting pipelines through heat insulation, heat preservation, and pipeline protection, can solve the problems of single cooling means, large safety hazards, and poor applicability, and achieve convenient and fast operation, safe blasting operations, and heat conduction The effect of a small coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

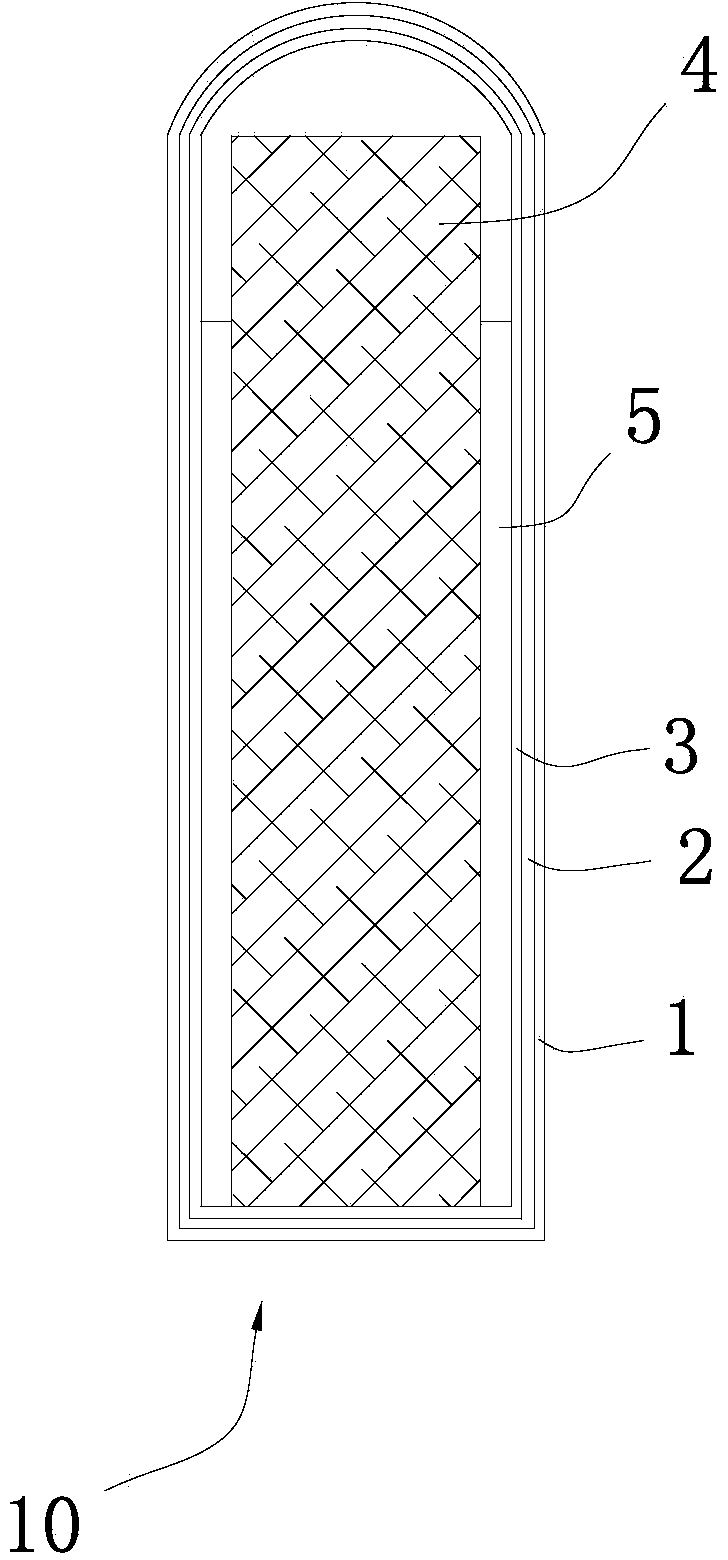

[0020] figure 1 A schematic diagram showing the structure of the first embodiment of the heat-resistant and heat-insulating sheath of the present invention, the heat-resistant and heat-insulating sheath is made of multi-layer heat-insulating and flame-retardant materials stacked and rolled into a cylinder with a cavity inside 10. The cylinder 10 is composed of three layers of fireproof layer 1, insulating layer 2 and waterproof layer 3 from the outside to the inside. The fireproof layer 1 can be made of fireproof aluminum foil cloth, which is composed of aluminum foil and glass fiber cloth. The insulating layer 2 can be made of ceramic fiber cloth, and the waterproof layer 3 can be formed of waterproof aluminum foil cloth. The waterproof aluminum foil cloth is composed of aluminum foil and polyester film. The upper and lower parts of the cylinder 10 are sealed to prevent liquid from penetrating into the multi-layer In the interlayer of the structure, one end of the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com