High temperature explosives for downhole well applications

a technology of explosives and wells, applied in the field of explosives, can solve the problems of high cost of explosive failure, increased risk of explosion,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following detailed description of the subject matter of the present invention, identified high temperature downhole explosives are principally described as being used in oil well applications. Such applications are intended for illustration purposes only and are not intended to limit the scope of the present invention. The identified high temperature downhole explosives can also be used to advantage in operations within gas wells, water wells, injection wells, and control wells. All such applications are intended to fall within the purview of the present invention. However, for purposes of illustration, the identified high temperature downhole explosives will be described as being used for oil well applications.

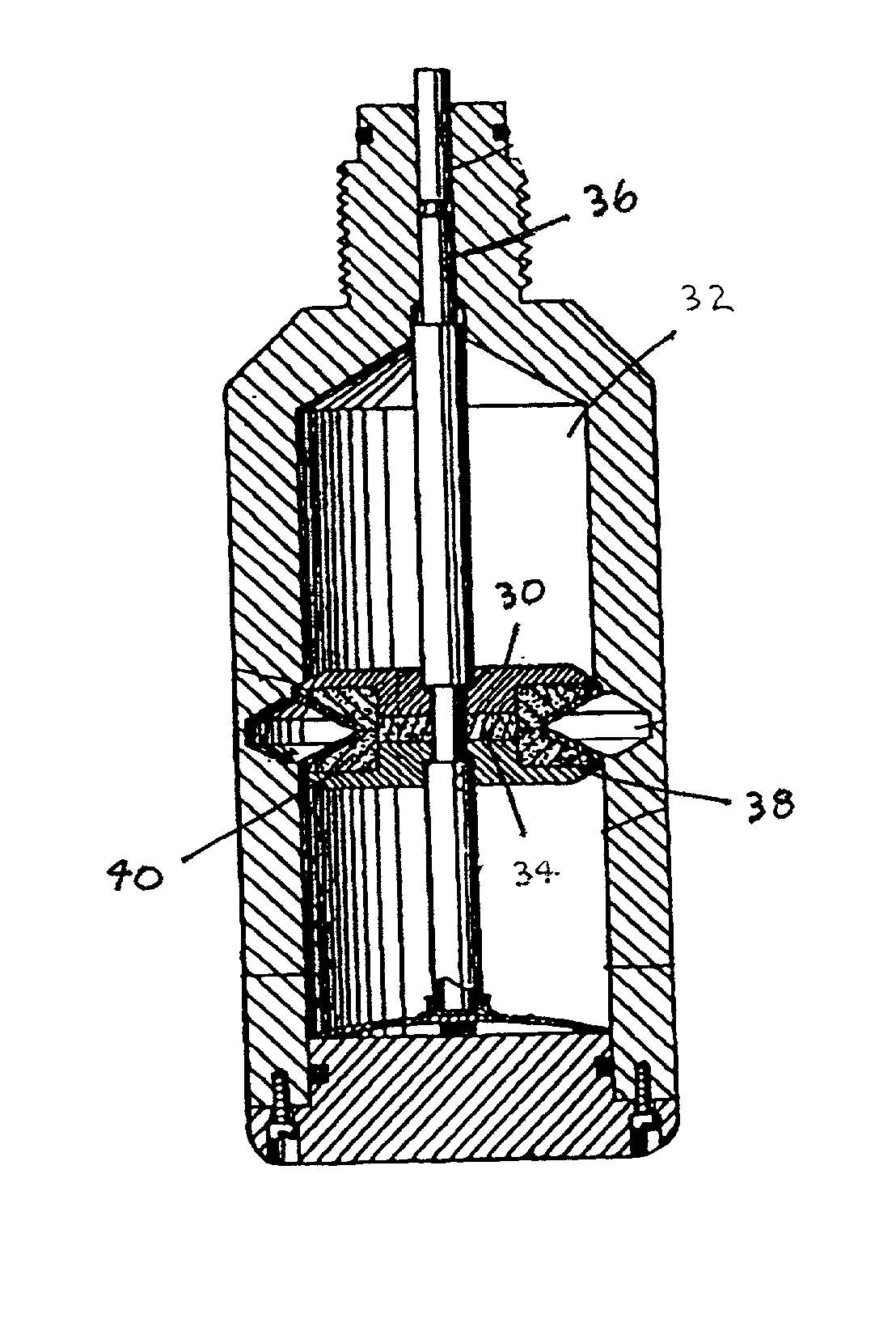

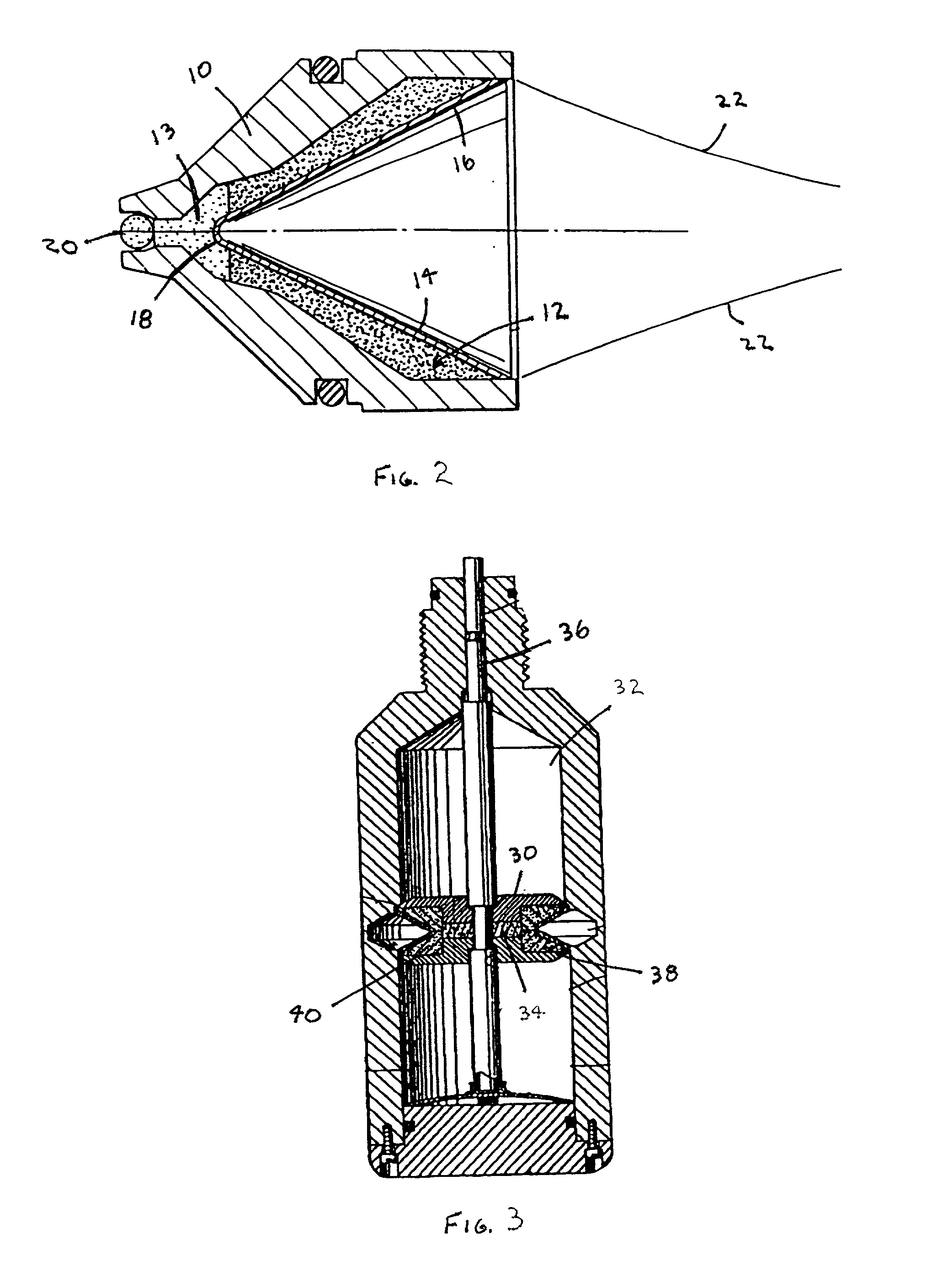

[0018] As shown in FIG. 1, the identified high temperature downhole explosives are principally described as being used in downhole well devices that are part of a tool string. The identified high temperature downhole explosives of the present invention can be us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com