Rapid product remodeling method, mold and rapid product molding method

A molding method and product technology, applied in the field of rapid prototyping of molds and products, and rapid product re-molding, can solve the problems of complex process and high cost, and achieve the effect of simple and easy process, extremely low cost, and difficult deformation of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

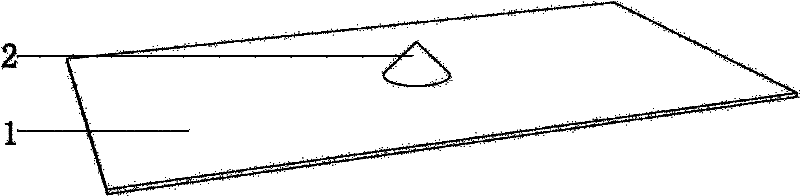

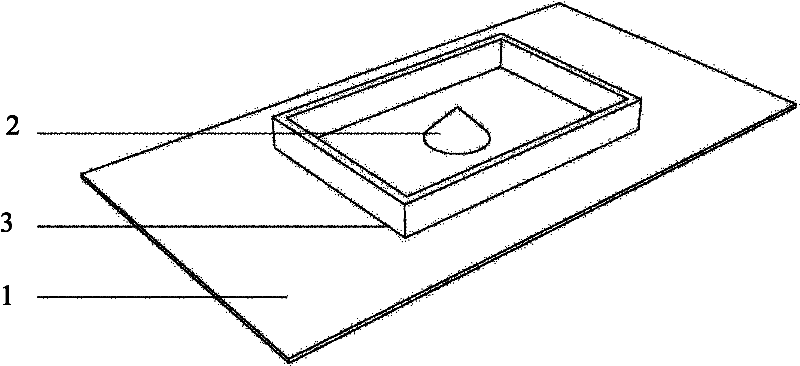

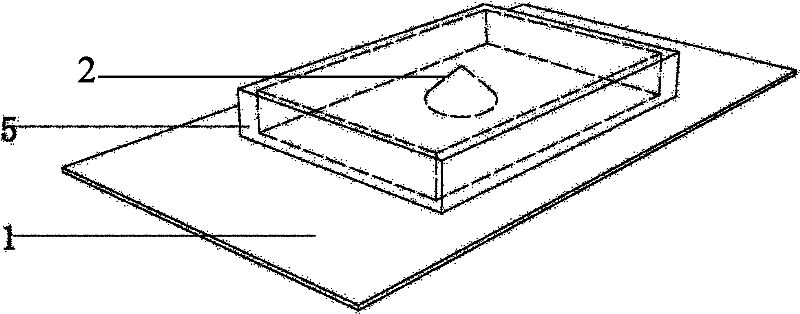

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] The present invention provides a kind of technological method that can rapidly make shaped product, comprise the method for rapid remodeling of product, namely the duplication of mould, and the method for rapid prototyping of product, namely utilize the remade mould to make product, the technology of the present invention not only It is easy to learn and has extremely low cost. It can also produce more precise products and the material is hard and not easy to deform. It is the best choice for making prototype models and handicrafts. It solves the problems of cost, time and product uniformity in small and medium-scale production.

[0030] The basic principle of the invention is to wrap the prototype of the industrial product with a soft, pull-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com