Novel pressure-resistant anti-cracking water permeable brick

A technology of permeable bricks and pressure resistance, applied in the field of building materials, can solve the problems of easy cracking, insufficient strength of permeable bricks, insufficient pressure resistance and crack resistance of brick bodies, etc., and achieve good hydrophobic performance, improve water permeability, and improve phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

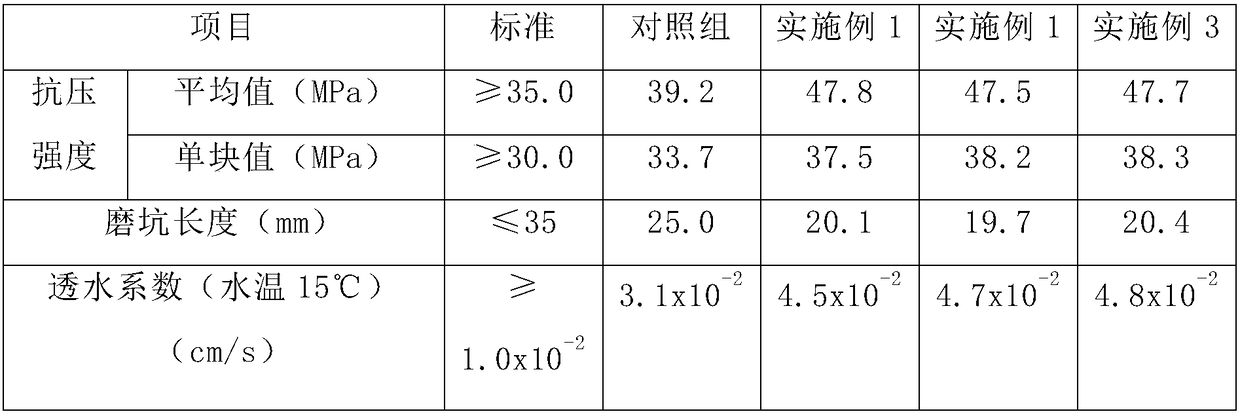

Examples

Embodiment 1

[0028] A new type of pressure-resistant and crack-resistant permeable brick. According to the mass parts, the raw materials of the permeable brick include the following components: 75 parts of basalt aggregate, 15 parts of quartz sand, 20 parts of cement, 11 parts of fly ash, 4 parts of inorganic pigment, 1 part of octadecyltrimethylammonium chloride, 0.5 part of foaming agent, 13 parts of hydrophobic modified mineral fiber, 1 part of water reducer, 24 parts of water.

[0029] In this embodiment, the hydrophobically modified mineral fiber is an inorganic fiber treated with surface hydrophobic modification, and the inorganic fiber is obtained by mixing brucite fiber and wollastonite fiber at a mass ratio of 3:1 to obtain a mineral fiber mixture. The fiber length is 2-3mm.

[0030] The hydrophobic modification treatment method of inorganic fibers is as follows: according to the mass fraction, 45 parts of inorganic fibers, 11 parts of boric acid, and 10 parts of nitric acid with ...

Embodiment 2

[0040] A new type of pressure-resistant and crack-resistant permeable brick. According to the mass parts, the raw materials of the permeable brick include the following components: 85 parts of basalt aggregate, 18 parts of quartz sand, 25 parts of cement, 14 parts of fly ash, 7 parts of inorganic pigment, 2 parts of octadecyltrimethylammonium chloride, 1.7 parts of foaming agent, 17 parts of hydrophobically modified mineral fiber, 2 parts of water reducing agent, and 27 parts of water.

[0041]In this embodiment, the hydrophobically modified mineral fiber is an inorganic fiber treated with surface hydrophobic modification, and the inorganic fiber is obtained by mixing brucite fiber and wollastonite fiber at a mass ratio of 3:1 to obtain a mineral fiber mixture. The fiber length is 2-3mm.

[0042] The hydrophobic modification treatment method of inorganic fibers is as follows: according to the mass fraction, 45 parts of inorganic fibers, 11 parts of boric acid, and 10 parts of ...

Embodiment 3

[0052] A new type of pressure-resistant and crack-resistant permeable brick. According to the mass parts, the raw materials of the permeable brick include the following components: 80 parts of basalt aggregate, 16 parts of quartz sand, 23 parts of cement, 13 parts of fly ash, 5.5 parts of inorganic pigment, 1.5 parts of octadecyltrimethylammonium chloride, 0.9 parts of foaming agent, 15 parts of hydrophobically modified mineral fiber, 1.5 parts of water reducing agent, and 26 parts of water.

[0053] In this embodiment, the hydrophobically modified mineral fiber is an inorganic fiber treated with surface hydrophobic modification, and the inorganic fiber is obtained by mixing brucite fiber and wollastonite fiber at a mass ratio of 3:1 to obtain a mineral fiber mixture. The fiber length is 2-3mm.

[0054] The hydrophobic modification treatment method of inorganic fibers is as follows: according to the mass fraction, 45 parts of inorganic fibers, 11 parts of boric acid, and 10 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com