Amphiphilic cobalt-containing sandwich type heteropolyacid and application thereof

A sandwich type, heteropolyacid technology, applied in the refining of oxygenated compounds, treatment of hydrocarbon oils, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of less research and achieve high desulfurization and desulfurization efficiency reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

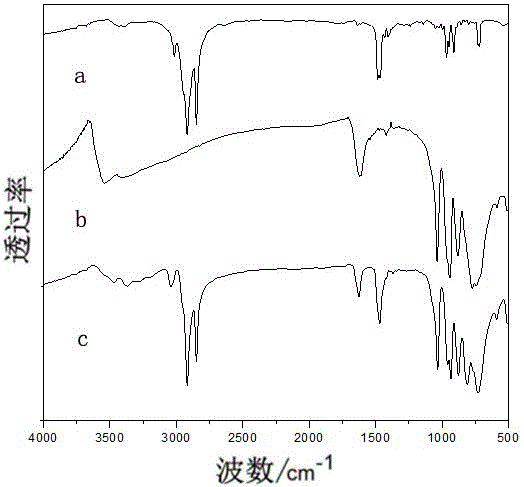

[0022] The concrete synthetic steps of described a kind of amphipathic cobalt-containing sandwich type heteropolyacid are as follows:

[0023] (1) Synthesis of cobalt-containing sandwich heteropolyacids :

[0024] Dissolve 0.41g of cobalt nitrate in 15ml of ionized water, and add 2.0g of phosphotungstic acid (A-PW 9 ), heating the solution to a homogeneous burgundy color, adding excess potassium chloride (4-6g) to the above solution to generate a blue-purple precipitate, cooling to room temperature and drying by suction, redissolving the solid powder in 5-10ml In hot water, recrystallize at 5°C, and collect blue-purple crystals. Dry in a vacuum oven for 2 hours;

[0025] (2) Synthesis of amphiphilic cobalt-containing sandwich heteropolyacids:

[0026] Concentration is the ethanol solution of surfactant of 1mol / L and slowly adds dropwise in the aqueous solution of cobalt-containing sandwich-type heteropolyacid that is 0.1mol / L with the same volume concentration, wherein the...

Embodiment 2

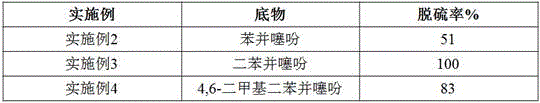

[0027] Example 2: Extraction and catalytic oxidation desulfurization experiment of simulated oil containing benzothiophene:

[0028] Take 0.73g benzothiophene and 0.5g biphenyl dissolved in n-octane, prepare 500mL simulated oil containing benzothiophene 500ppm, then mix 23mg catalyst prepared above, 21μL hydrogen peroxide, 1mL ionic liquid [Bmim]PF 6 , 5mL simulated oil was added to a 25mL round-bottomed flask in sequence, and the reaction was carried out under magnetic stirring at 60°C for 60 minutes. The supernatant was taken out every 10 minutes, and analyzed by gas chromatography. The experimental results are shown in Table 1. After the reaction is over, use the pouring method to pour out the remaining simulated oil. After washing several times with dichloromethane, the catalyst and the ionic liquid were centrifuged and separated, and placed in a vacuum drying oven for 6 hours, and the catalyst was obtained again for the next round of reaction. The catalytic efficiency di...

Embodiment 3

[0029] Example 3: Extraction and catalytic oxidation desulfurization experiment of simulated oil containing dibenzothiophene:

[0030] Get 1.0g dibenzothiophene and 0.5g biphenyl to be dissolved in n-octane, be mixed with 500mL the simulated oil product that contains dibenzothiophene 500ppm, then 23mg catalyst prepared above, 21μL hydrogen peroxide, 1mL ionic liquid [Bmim ]PF 6 , 5mL simulated oil was added to a 25mL round bottom flask in turn, and the reaction was performed under magnetic stirring at 60°C for 80 minutes. The supernatant was taken out every 10 minutes, and analyzed by gas chromatography. The experimental results are shown in Table 1. After the reaction is over, use the pouring method to pour out the remaining simulated oil. After washing with dichloromethane for several times, the catalyst and the ionic liquid were centrifuged and separated, and placed in a vacuum drying oven for 8 hours, and the catalyst was obtained again for the next round of reaction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com