Clean fracturing fluid for low-temperature coal-bed gas reservoirs and application thereof

A technology for cleaning fracturing fluids and coalbed methane, applied in drilling compositions, production fluids, wellbore/well components, etc., can solve the problems of poor thickening ability, high price, poor temperature resistance, etc. Good temperature and shear resistance, low configuration cost and good sand-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

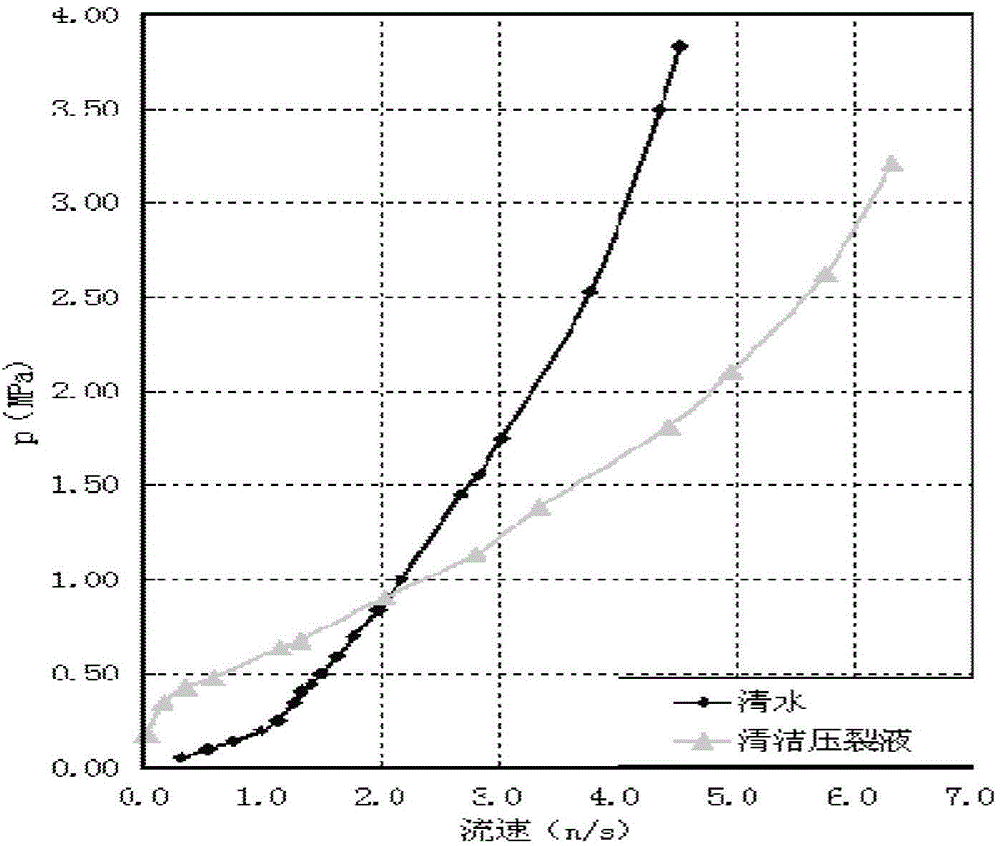

Image

Examples

Embodiment 1

[0029] The weight percentages of the components of the clean fracturing fluid are: octadecyltrimethylammonium chloride, 0.4%; sodium salicylate, 0.15%; potassium chloride, 1.0%; pH regulator, 0.06%; anti-residue agent , 0.08%; clear water, 98.31%.

[0030] Preparation of clean fracturing fluid: Add water into a large liquid mixing tank, add salicylate, potassium chloride, pH regulator and anti-residue agent in sequence under stirring conditions, and then add octadecyl trimethazine after completely dissolving ammonium chloride. Under stirring conditions, the concentration or viscosity of the liquid in the large tank is made uniform, and the obtained clean fracturing fluid is kept at 27°C for 100s -1 , shear for 10 minutes, the viscosity is 30mpa·s, and the sand sedimentation velocity is 0.128cm / min.

Embodiment 2

[0032] The weight percentages of the components of the clean fracturing fluid are: octadecyltrimethylammonium chloride, 0.3%; sodium salicylate, 0.15%; potassium chloride, 1.0%; pH regulator, 0.06%; anti-residue agent , 0.08%; clear water, 98.41%. Configure it as clean fracturing fluid, 27°C, 100s -1 , shear for 10 minutes, the viscosity is 25mpa·s, and the sand sedimentation velocity is 0.20cm / min.

Embodiment 3

[0034] The weight percentages of the components of the clean fracturing fluid are: cetyltrimethylammonium chloride, 0.4%; salicylate, 0.15%; potassium chloride, 1.0%; pH regulator, 0.06%; anti-residue agent , 0.08%; clear water, 98.31%. Configure it as clean fracturing fluid, 27°C, 100s -1 , sheared for 10 minutes, the viscosity was 25mpa·s, and the sand sedimentation velocity was 0.19cm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com