Preparation method of novel ABS resin based material

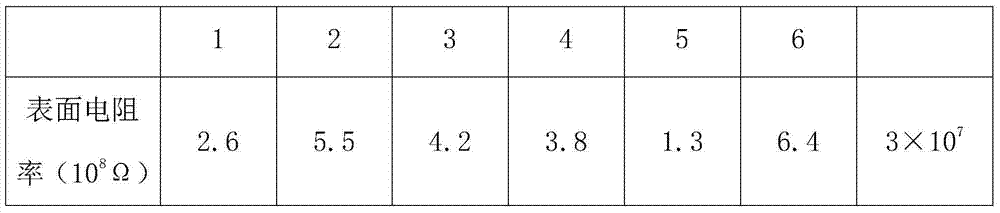

A technology of ABS resin and base material, applied in the field of preparation of ABS resin base material, can solve the problems of high surface resistivity, limited application scope, etc., and achieve the effect of improving electrical conductivity and antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of ABS resin-based material, the steps are as follows:

[0027] (1) Add montmorillonite to deionized water and stir for 1 hour to obtain a montmorillonite suspension solution for 10 hours, add the phosphoric acid solution of octadecyltrimethylammonium chloride to the montmorillonite suspension solution, and The mass ratio of soil to octadecyltrimethylammonium chloride is 6:1, heat and stir at 90°C for 1 hour, then let it stand for 10 hours, take it out, filter, vacuum dry to constant weight, put it in a ball mill and pulverize it to obtain organic Montmorillonite;

[0028] (2) adding the organic montmorillonite, polyaniline and the hydrochloric acid solution with a mass fraction of 10% into the three-port reactor together for magnetic stirring, and adding dropwise the ammonium sulfate solution with a mass fraction of 10%, organic The mass ratio of montmorillonite, polyaniline, hydrochloric acid, and ammonium persulfate is 20:18:1:3. After 2 hours, ...

Embodiment 2

[0033] A preparation method of ABS resin-based material, the steps are as follows:

[0034] (1) Add montmorillonite to deionized water and stir for 1 hour to obtain a montmorillonite suspension solution for 10 hours, add the phosphoric acid solution of octadecyltrimethylammonium chloride to the montmorillonite suspension solution, and The mass ratio of soil to octadecyltrimethylammonium chloride is 6:1, heat and stir at 90°C for 1 hour, then let it stand for 10 hours, take it out, filter, vacuum dry to constant weight, put it in a ball mill and pulverize it to obtain organic Montmorillonite;

[0035] (2) adding the organic montmorillonite, polyaniline and the hydrochloric acid solution with a mass fraction of 10% into the three-port reactor together for magnetic stirring, and adding dropwise the ammonium sulfate solution with a mass fraction of 10%, organic The mass ratio of montmorillonite, polyaniline, hydrochloric acid, and ammonium persulfate is 20:18:1:3. After 2 hours, ...

Embodiment 3

[0040] A preparation method of ABS resin-based material, the steps are as follows:

[0041](1) Add montmorillonite to deionized water and stir for 1 hour to obtain a montmorillonite suspension solution for 10 hours, add the phosphoric acid solution of octadecyltrimethylammonium chloride to the montmorillonite suspension solution, and The mass ratio of soil to octadecyltrimethylammonium chloride is 6:1, heat and stir at 90°C for 1 hour, then let it stand for 10 hours, take it out, filter, vacuum dry to constant weight, put it in a ball mill and pulverize it to obtain organic Montmorillonite;

[0042] (2) adding the organic montmorillonite, polyaniline and the hydrochloric acid solution with a mass fraction of 10% into the three-port reactor together for magnetic stirring, and adding dropwise the ammonium sulfate solution with a mass fraction of 10%, organic The mass ratio of montmorillonite, polyaniline, hydrochloric acid, and ammonium persulfate is 20:18:1:3. After 2 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com