Slide-making staining machine and method for slide-making staining method

A dyeing machine and dye solution technology, applied in the field of production dyeing, can solve the problems of artificial dyeing, cell morphology damage, complex structure, etc., and achieve the effects of avoiding the interference of human factors, stable production quality, and stable cantilever operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

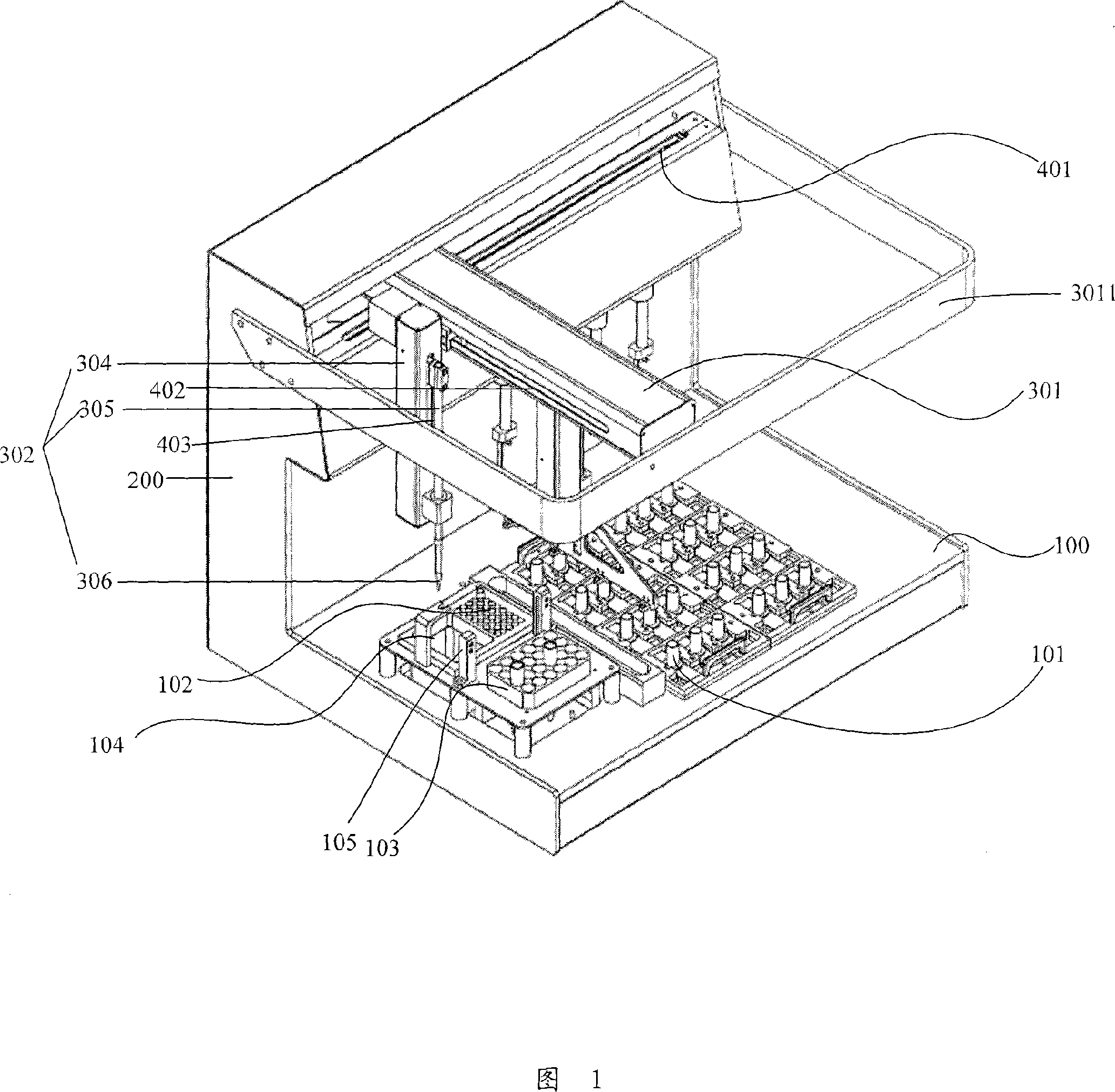

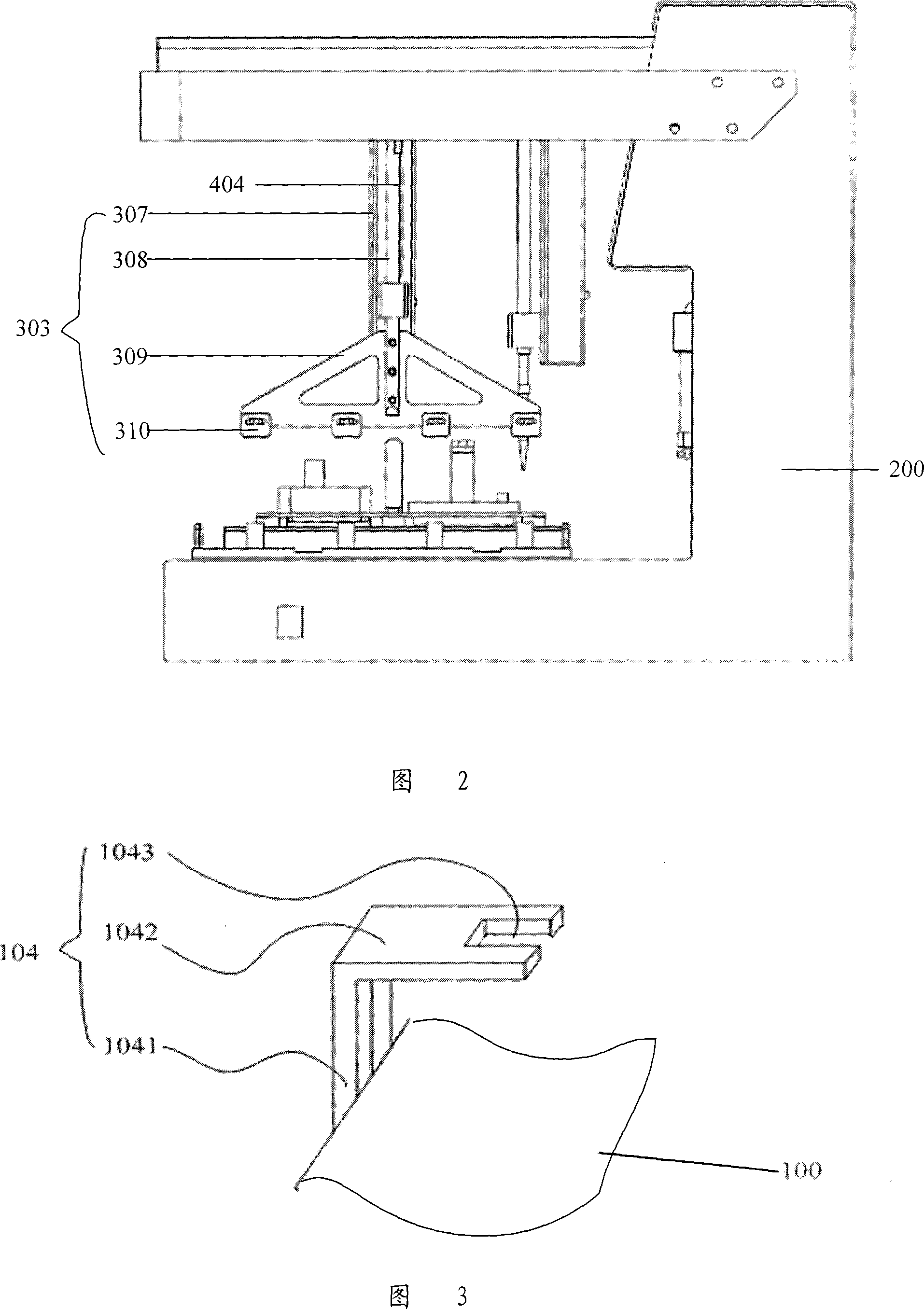

[0047] Referring to FIGS. 1-8 , the slide dyeing machine of the present invention includes a dyeing platform 100 , a carrier 200 vertically connected to the dyeing platform 100 , and a moving device 300 slidably connected to the carrier 200 .

[0048] The staining platform 100 is respectively provided with a staining chamber 101 with glass slides therein, a pipette 102 for transferring liquid, a test tube rack 103 inserted with a test tube containing a sample separation extract, a recovery device 104 and an infrared ray. Detector 105.

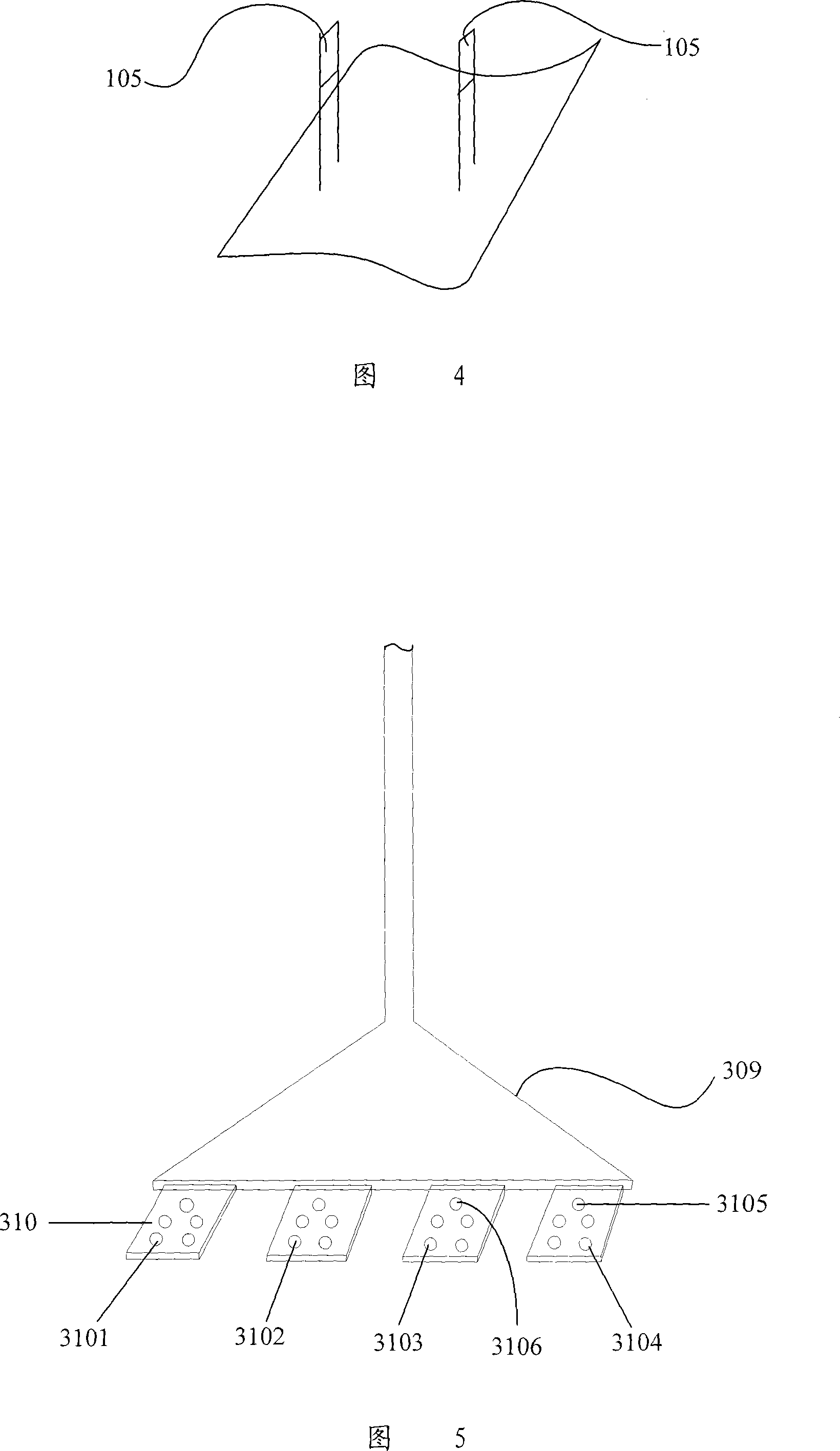

[0049] Referring to FIG. 3 , the recovery device 104 includes a bracket 1041 and a fixing piece 1042 vertically connected to the bracket 1041 . A concave opening 1043 is defined on the edge of the fixing piece 1042 . The concave opening 1043 can also be opened on the position of the fixing piece 1042 except the side connected with the bracket 1041 . The width of the concave opening 1043 is smaller than the diameter of the pipette 102 but larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com