Method of separating fischer-tropsch synthesis heavy distillate from ferrous iron-base catalyst

An iron-based catalyst and Fischer-Tropsch synthesis technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of adsorption catalyst recovery, difficult utilization, complex equipment, etc., and achieve long-term stable operation and reduce load , Improve the effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

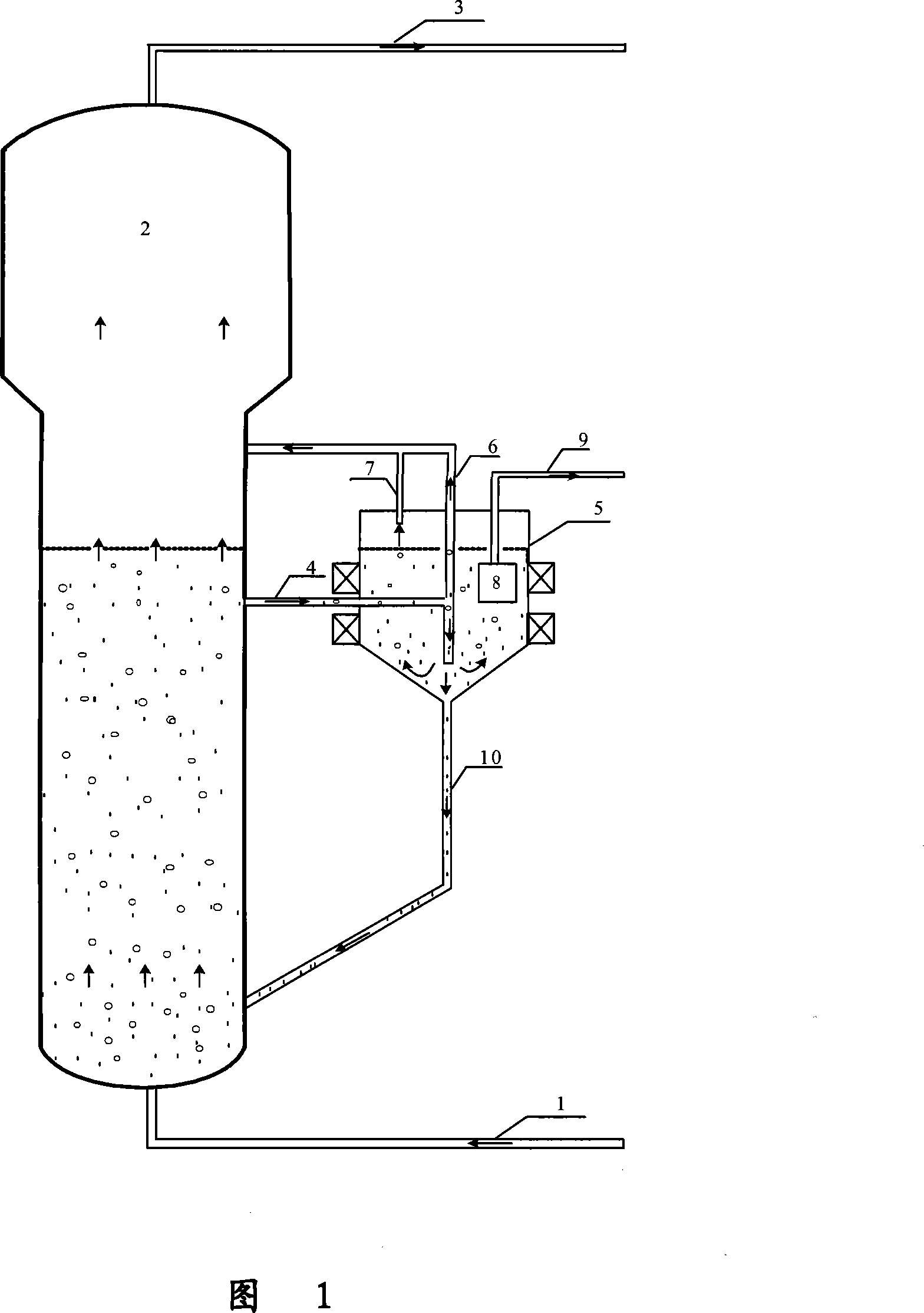

Image

Examples

Embodiment 1

[0023] The processing capacity of the Fischer-Tropsch synthesis unit is 240,000 tons per year. The iron-based catalyst used can be the Fischer-Tropsch synthesis catalyst produced by patent US5324335, US454671 or CN1233463C. The main active component of the catalyst is Fe-Cu-K.

[0024]The heavy fraction of the Fischer-Tropsch synthesis product and the iron-based catalyst are separated by the method of the invention. The slurry formed by the catalyst and the Fischer-Tropsch synthesis product is drawn from the slurry bed reactor, the concentration of the catalyst in the slurry is 30w%, and the gas holdup of the slurry is 15%. The weight flow rate of the slurry extracted from the slurry bed reactor is 150 tons / hour, and the residence time of the slurry in the settling tank outside the device is 20 minutes. In the settling tank, the slurry is subjected to the action of a magnetic field in the direction of the magnetic force line, and the magnetic field strength is 1500 Gauss, so t...

Embodiment 2

[0026] The device and main test steps are basically the same as in Example 1. The slurry formed by the catalyst and the Fischer-Tropsch synthesis product is drawn from the slurry bed reactor, the concentration of the catalyst in the slurry is 30w%, the gas holdup of the slurry is 15%, the pumping amount of the slurry is 150 tons / hour, and the slurry is outside the device The residence time in the settling tank is 8 minutes, the applied magnetic field strength is 2000 gauss, the concentration of the catalyst contained in the Fischer-Tropsch synthesis product at the position of the filter is lower than 1w%, and the filtration accuracy of the filter is 5 microns. The weight flow rate of the Fischer-Tropsch synthesis product discharged through the filter is 30 tons / hour, the content of catalyst particles and powder in the discharged Fischer-Tropsch synthesis product is less than 100ppm, and the stable operation time of the device is more than 5000 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com