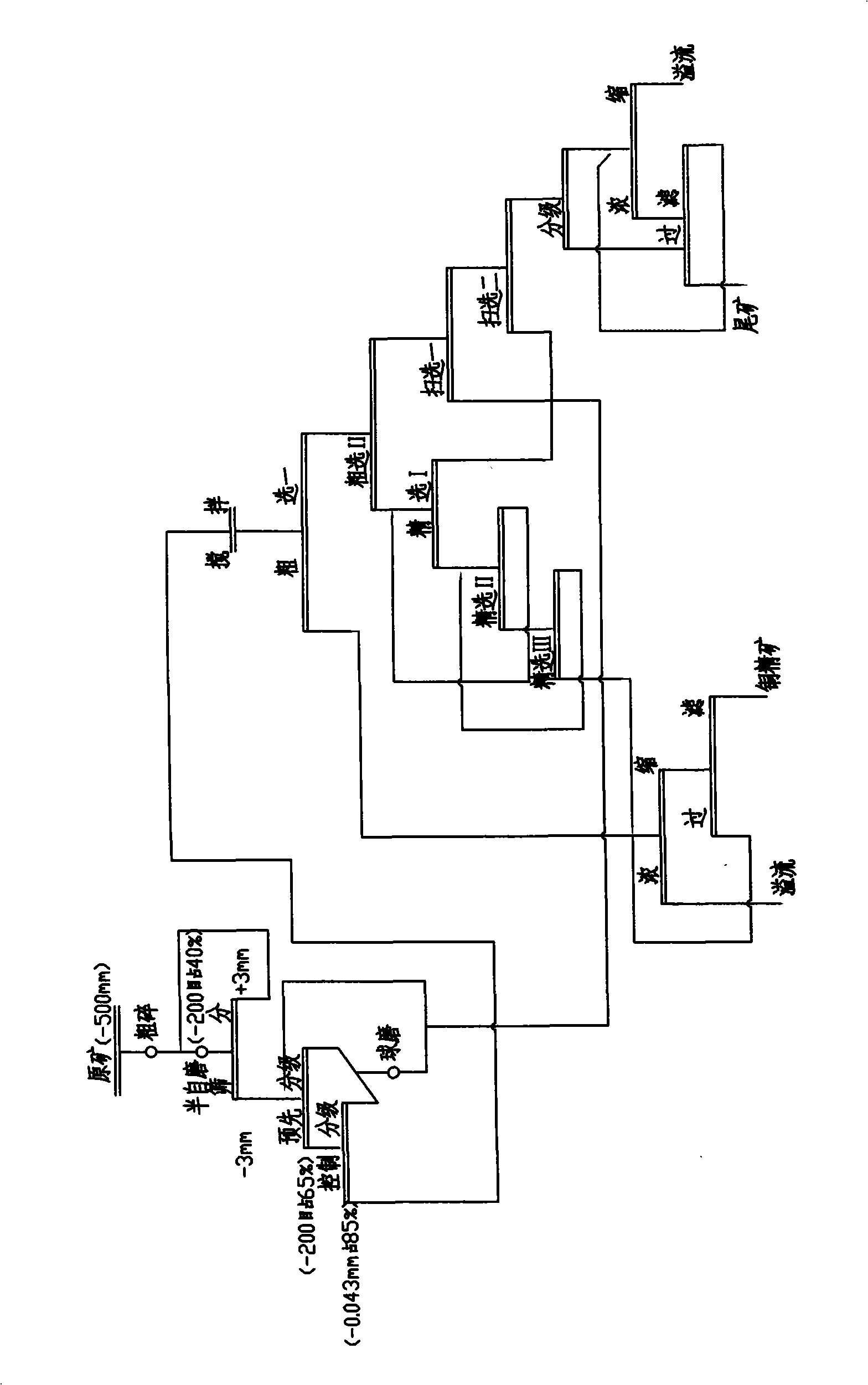

Beneficiation process of mixed dregs using three copper smelting methods of flash smelting furnace, revolving furnace and depletion electric furnace

A technology of depleted electric furnace and flash furnace, which is applied in the mineral processing field of mixed slag of copper smelting process of flash furnace, converter and depleted electric furnace. The effect of low equipment repair and maintenance rate, improved flotation index, and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] This new process is applied to various mixed slag beneficiation, and the properties of the three kinds of slag are as follows:

[0008] 1. Flash furnace is the slag produced by smelting copper concentrate through flash furnace. The nature of the slag is related to the copper concentrate and large composition of the furnace and the smelting operating conditions. The main components are copper sulfide, copper metal, olivine, iron oxide, ballast, iron glass body and so on. Slag composition: Cu 2%, Fe 40%, SiO2 28.5%.

[0009] 2. Converter slag is the slag produced by matte copper smelting in the converter, and its properties are determined by the matte copper composition, smelting operation conditions and slag cooling speed. The main ingredients are iron, olivine, magnetite, white matte and matte. Slag composition: Cu 5%, Fe 44%, SiO2 22.0%.

[0010] 3. Diluted electric furnace slag is the slag produced after the copper concentrate is smelted in a flash furnace and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com