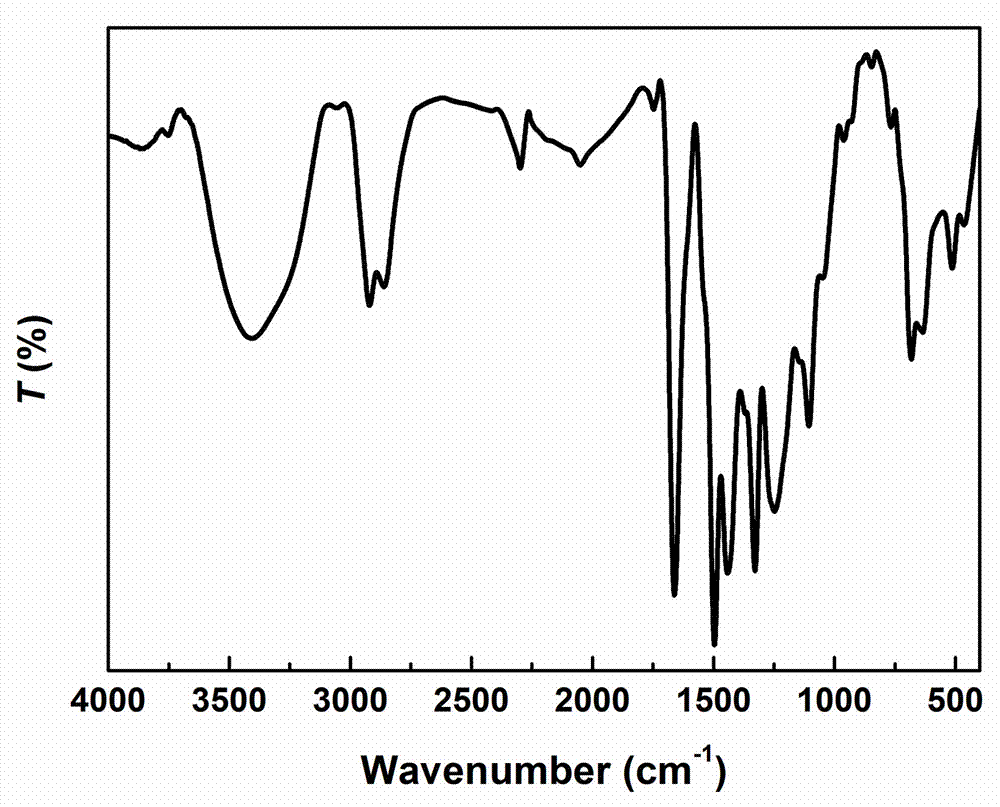

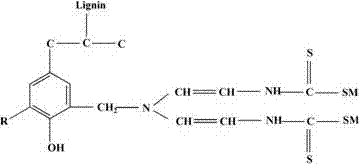

Lignin-based dithiocarbamate heavy metal ion capture agent and preparation method

A technology of prime dithiocarbamic acid and prime dithioamino, applied in the treatment of heavy metal-contaminated soil, heavy metal ion wastewater, lignin-based dithiocarbamate heavy metal ion scavenger and preparation field , can solve the problems of high cost of use and restrictions on the large-scale promotion and application of DTC, and achieve the effects of not being prone to secondary pollution, strong heavy metal ion capture ability, and simple use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

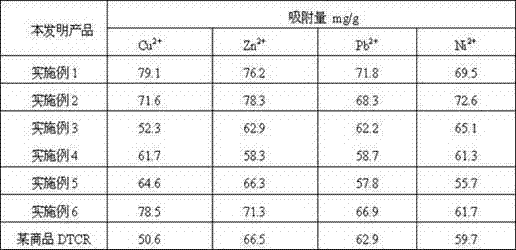

Embodiment 1

[0039] The operation steps of the preparation method of the lignin-based dithiocarbamate heavy metal ion scavenger are as follows: under normal pressure, take 100g alkali lignin and dissolve it in distilled water to prepare a mixed solution with a mass fraction of 30%, add hydrogen Sodium oxide adjusted the pH of the mixture to 11, and then added H 2 o 2 Oxidant 13.88g, under mechanical stirring (300 r min -1 ) under heating to 90°C, react for 1 hour; add 43.55g of diethylenetriamine, keep the reaction temperature unchanged, then slowly drop in 21.23g of formaldehyde (about 30 minutes to finish dripping, so as not to overflow when the temperature is too high), and stir Under reflux reaction for 5 hours; cool the above solution to room temperature, add an appropriate amount of sodium hydroxide to maintain the pH of the mixed solution = 11, slowly add 52.8g of carbon disulfide dropwise, after the dropwise addition is complete, heat up to 45°C and react for 5 hours, then continu...

Embodiment 2

[0043] The operation steps of the preparation method of the lignin-based dithiocarbamate heavy metal ion scavenger are as follows: under normal pressure, take 100g alkali lignin and dissolve it in distilled water to prepare a mixed solution with a mass fraction of 25%, add hydrogen Potassium oxide was used to adjust the pH to 10, and then 4.08 L of oxygen was introduced into the mixture under mechanical stirring (300 r min -1 ) and heated to 80°C, reacted for 2 hours; added 16.28g of triethylenetetramine, kept the reaction temperature constant, then slowly added 8.33g of formaldehyde (dropped in about 30 minutes, so as not to overflow when the temperature was too high), and stirred reflux for 6 hours; cool the above solution to room temperature, add potassium hydroxide to maintain the pH of the reaction solution = 10, slowly add 19.6 g of carbon disulfide dropwise, wait until the dropwise addition is complete, heat up to 42 ° C and react for 5 hours, continue to add modified A...

Embodiment 3

[0046] The operation steps of the preparation method of the lignin-based dithiocarbamate heavy metal ion scavenger are as follows: under normal pressure, take 100g alkali lignin and dissolve it in distilled water to prepare a mixed solution with a mass fraction of 35%, add hydrogen Potassium oxide and sodium hydroxide were used to adjust the pH to 9, then 10 g of Fenton’s reagent was added, and the mixture was stirred mechanically (300 r min -1 ) to 90°C, and react for 2 hours; add 5.0g of diethylenetriamine and 3.4g of melamine, keep the reaction temperature constant, and then slowly drop in 20.09g of formaldehyde (about 30 minutes to finish dripping, so as not to overheat and overflow ), reflux reaction under stirring for 6 hours; the above solution was cooled to room temperature, and sodium hydroxide was added to adjust the pH=10 of the mixed solution, and a total of 16.87 g of carbon disulfide was slowly added dropwise. , continue to add modifier urea 8.0g, polyacrylamide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com