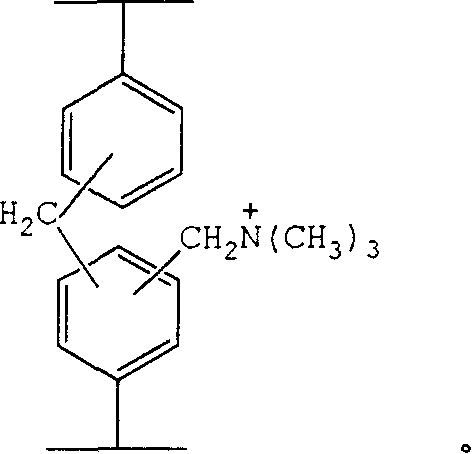

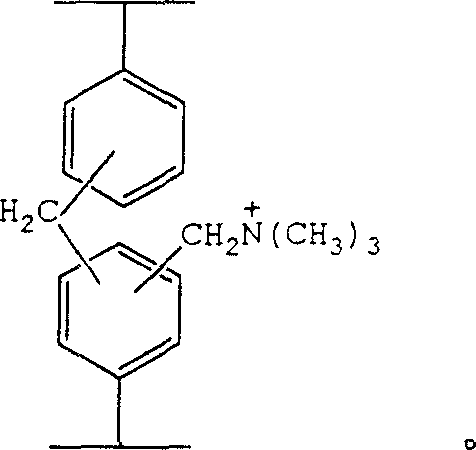

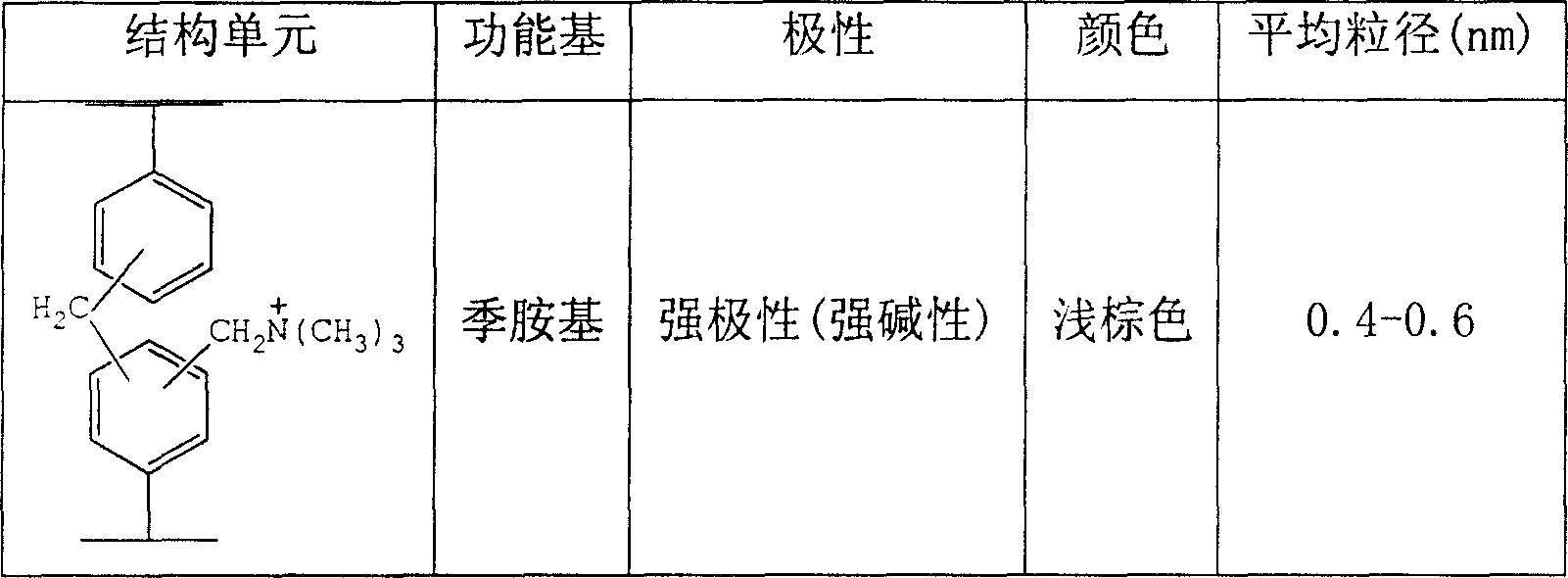

Composite functional super high cross-linked adsorption resin containing quaternary amine group, and its preparation method

A technology with ultra-high cross-linking and composite functions, which can be used in chemical instruments and methods, other chemical processes, etc., and can solve the problems of limited adsorption performance, low specific surface area, and poor organic adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Suspension polymerization.

[0024] Add a certain amount of dilute sodium hydroxide solution to the styrene monomer or directly filter the monomer through a resin column equipped with a strong base anion exchange resin to remove the polymerization inhibitor.

[0025] In a 1000mL beaker, add 210g styrene, 26g divinylbenzene, and 140g liquid paraffin, stir well and set aside.

[0026] In a 1000mL three-neck flask, add 600g of distilled water and raise the temperature to 40°C, then add 6g of gelatin, stir until completely dissolved, and at the same time raise the temperature to 50°C, add 2mL of methylene blue, stir well, add the above-mentioned styrene, divinylbenzene and liquid Add the initiator benzoyl peroxide 4.0g to the wax mixture; adjust the stirring speed to make the oil droplet size appropriate, gradually raise the temperature to 80°C at a speed of 1°C / 6min, keep it warm for 4 hours, and then gradually raise the temperature to 85°C Keep warm for 3 hours, keep ...

Embodiment 2

[0039]The synthetic steps of another embodiment of the present invention are as follows:

[0040] A) Using styrene as monomer, divinylbenzene as crosslinking agent, liquid wax as porogen, magnesium carbonate as dispersant, benzoyl peroxide as initiator, and suspension polymerization Linked macroporous polystyrene-divinylbenzene copolymer, steam distillation or extraction with ethanol as solvent to remove the residual porogen in the resin channels, and then air-dried to obtain low cross-linked macroporous polystyrene- Divinyl benzene resin, that is, white balls.

[0041] Wherein the dosage of the crosslinking agent is 4% of the total amount of the monomer and the crosslinking agent, the dosage of the porogen is 40% of the weight of the monomer, and the crosslinking degree of the low crosslinking macroporous polystyrene is 2%.

[0042] B) soak the white ball in chloromethyl ether which is 4 times its weight, add 20% zinc chloride of the white ball weight as a catalyst, and carr...

Embodiment 3

[0047] The synthetic steps of another embodiment of the present invention are as follows:

[0048] A) Use styrene as a monomer, divinylbenzene as a crosslinking agent, use No. 200 solvent oil as a porogen, and use gelatin (or polyvinyl alcohol, or a mixture of magnesium carbonate, gelatin, and polyvinyl alcohol) As a dispersant, use benzoyl peroxide as an initiator, and use suspension polymerization method to synthesize macroporous polystyrene-divinylbenzene copolymer with low crosslinking degree, and use ethanol (or acetone, industrial alcohol, low boiling point solvent gasoline) Perform solvent extraction to remove the porogen remaining in the resin channels, and then air-dry to obtain low-crosslinked macroporous polystyrene-divinylbenzene resin, that is, white balls.

[0049] Wherein the dosage of the crosslinking agent is 7% of the total amount of the monomer and the crosslinking agent, the dosage of the porogen is 100% of the weight of the monomer, and the crosslinking de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com