Method for controlloing oxygen containing functional group in surface in synthesizeing adsorptive resin of crosslinked polystyrene

A technology of cross-linked polystyrene and adsorption resin, applied in the direction of adsorption water/sewage treatment, etc., can solve the problem of lack of control and adjustment of oxygen-containing functional groups, and achieve the effect of simple equipment and simple control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Suspension polymerization

[0022] Add a certain amount of dilute sodium hydroxide solution to the styrene monomer or directly filter the monomer through a resin column equipped with a strong base anion exchange resin to remove the polymerization inhibitor, and use it after passing the inspection.

[0023] In a 1000mL beaker, add 200g styrene, 25g divinylbenzene, and 125g liquid paraffin, stir well and set aside.

[0024] In a 1000mL three-neck flask, add 600mL of pure water, raise the temperature to 40°C, then add 6g of gelatin, then raise the temperature to 50°C, and stir until the gelatin is completely dissolved. Add 2mL of methylene blue, stir evenly, then add the above mixture of styrene, divinylbenzene and paraffin, and add 4g of benzoyl peroxide. Adjust the appropriate stirring speed to make the size of the oil droplet suitable, raise the temperature to 80°C at a rate of 6°C for 1 minute and keep it warm for 4 hours, then raise the temperature to 85°C and kee...

Embodiment 2

[0033] 1. Using styrene as a monomer, divinylbenzene as a crosslinking agent, liquid wax as a porogen, gelatin as a dispersant, benzoyl peroxide as an initiator, and suspension polymerization to synthesize low crosslinking The macroporous styrene-divinylbenzene copolymer is extracted with ethanol as a solvent to remove the porogen remaining in the resin pores, and vacuum-dried to obtain white balls.

[0034] The amount of the porogen used is 40% of the monomer weight, and the cross-linking degree of the low-crosslinked macroporous polystyrene is 2%.

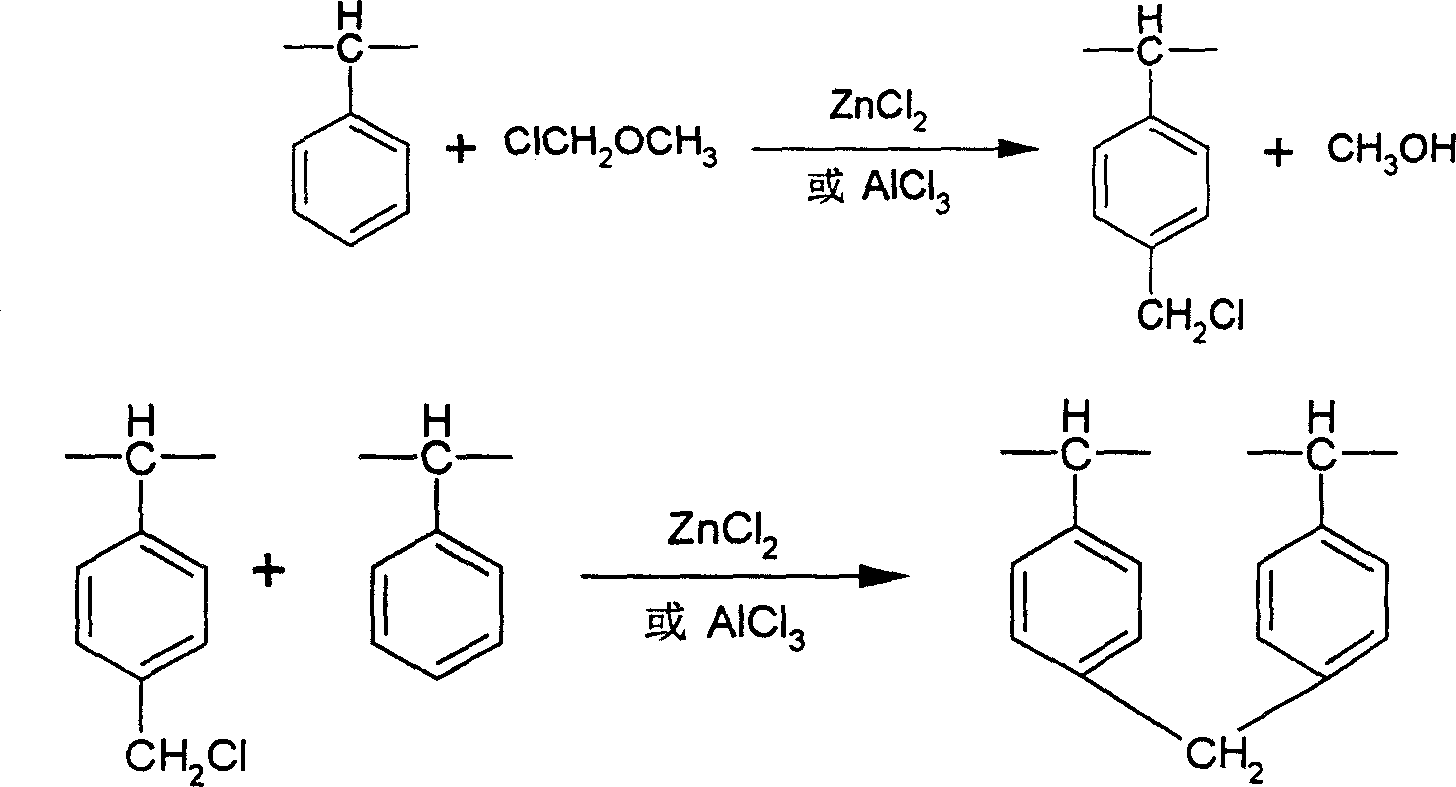

[0035] 2. Soak the white ball in 4 times the weight of chloromethyl ether, add zinc chloride with 30% of the weight of the white ball as a catalyst, carry out chloromethylation at 30°C, stop the reaction until the chlorine content reaches 18%, and filter out the resin spheres, wash the remaining chlorinated mother liquor in the resin with water, and vacuum-dry to obtain chlorine spheres.

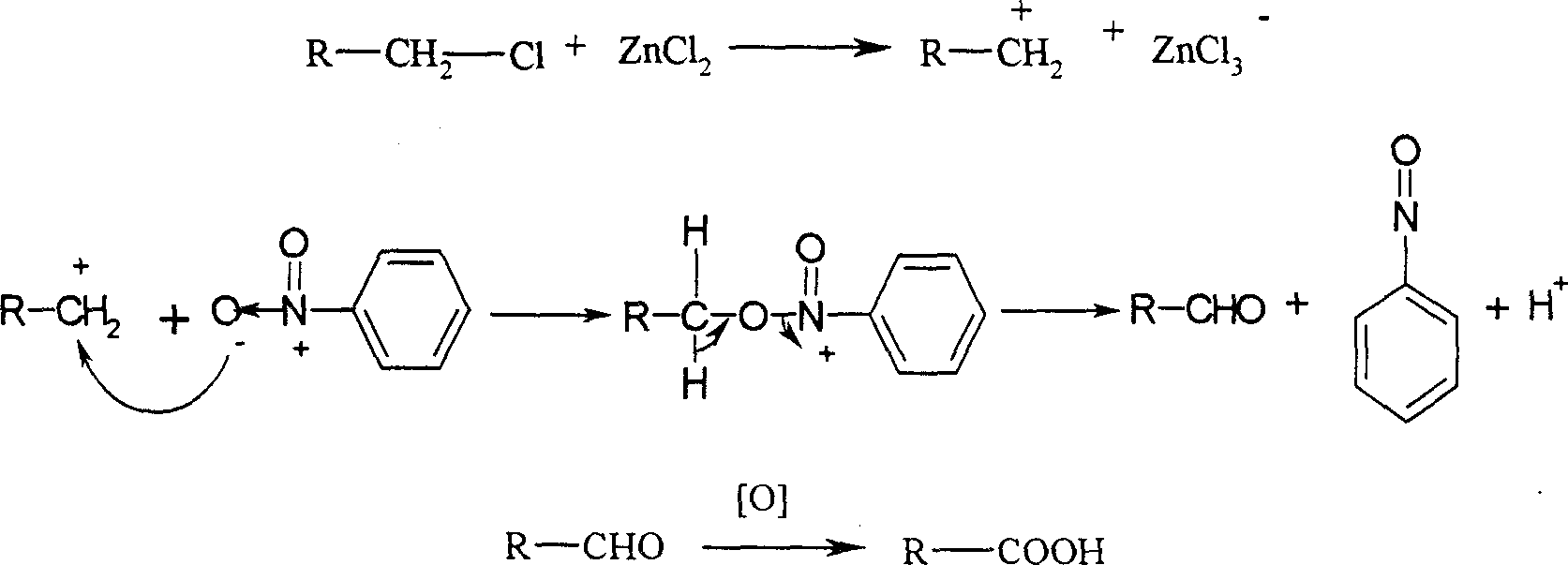

[0036] 3. Swell chlorine balls in nitro...

Embodiment 3

[0041] 1. Using styrene as a monomer, diethylene as a crosslinking agent, liquid wax as a porogen, magnesium carbonate as a dispersant, benzoyl peroxide as an initiator, and suspension polymerization to synthesize low crosslinking The macroporous styrene-divinylbenzene copolymer is extracted with ethanol as a solvent to remove the porogen remaining in the resin pores, and vacuum-dried to obtain white balls.

[0042] Wherein the amount of the porogen is 100% of the monomer weight, and the cross-linking degree of the low-crosslinked macroporous polystyrene is 2%.

[0043] 2. Soak the ball in 7 times the weight of chloromethyl ether, add zinc chloride with 50% of the weight of the white ball as a catalyst, carry out chloromethylation at 40°C, stop the reaction until the chlorine content reaches 18%, and filter out the resin ball , wash the remaining chlorinated mother liquor in the resin with water, and dry in vacuum to obtain chlorine balls.

[0044] 3. Swell chlorine balls in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com