Solar cell EVA packaging adhesive film material having light conversion function, and preparation method thereof

A solar cell and encapsulation adhesive film technology, which is applied in photovoltaic power generation, circuits, adhesives, etc., can solve the problems of increasing powder, unused, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

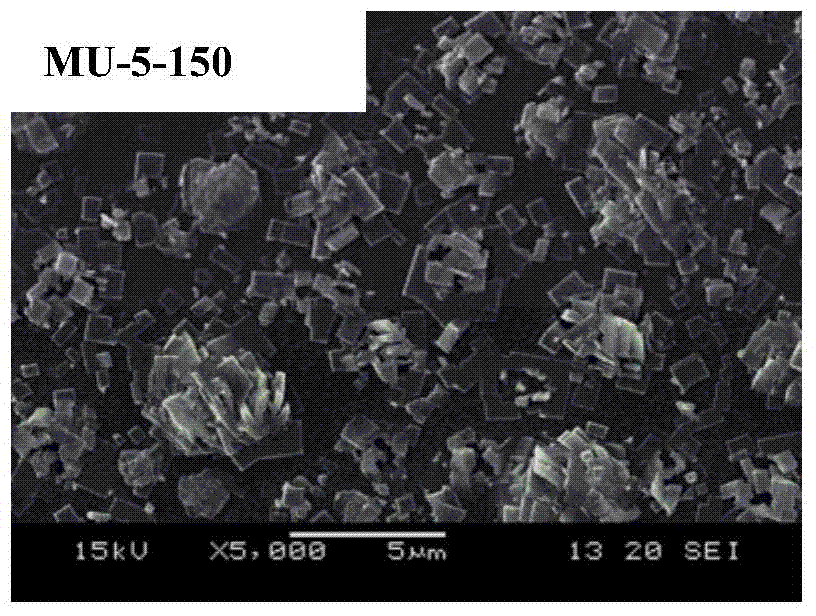

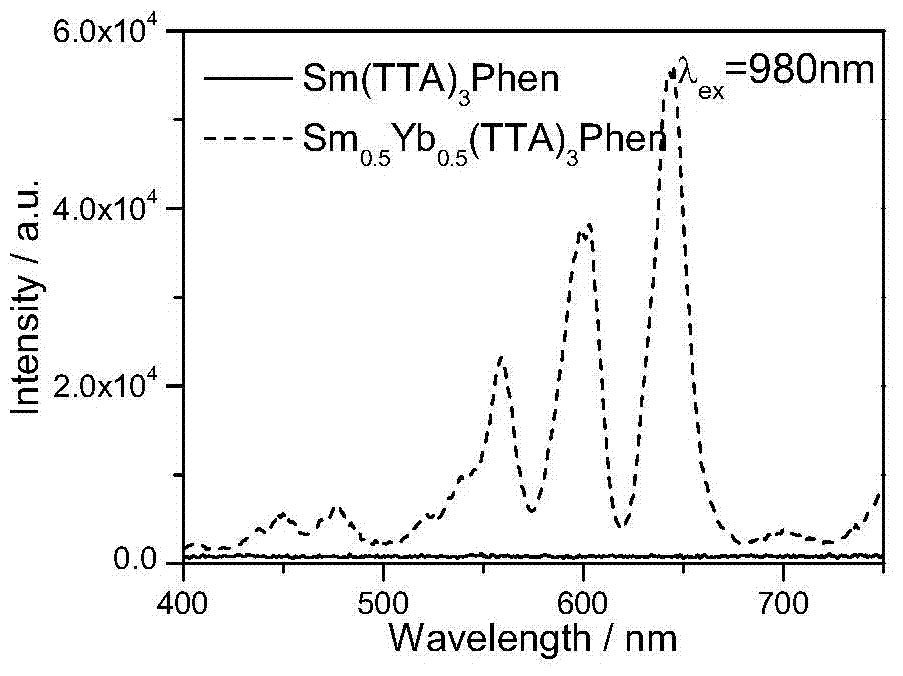

[0029] Preparation of Sm by Microwave Ultrasonic Method 0.5 Yb 0.5 (TTA) 3 Phen (MU-5-150) light-converting nanomaterials, weighing 3mmol samarium chloride (SmCl 3 ·6H 2 O)+3mmol ytterbium chloride (YbCl 3 ·6H2 (0) 40ml ethanol solution, 6mmol1,10-phenanthroline (Phen) 30ml ethanol solution, the ethanol solution of 18mmol α-thienoyl trifluoroacetone (HTTA) 70ml, in a microwave ultrasonic combined reactor (microwave power 500W, ultrasonic power 500W, reaction temperature 60°C, reaction time 60min) into a four-port flat-bottomed glass reaction vessel, first add HTTA solution, and then use a peristaltic pump to sequentially add SmCl 3 ·6H 2 O+YbCl 3 ·6H 2 For O solution and Phen solution, use 1mol / L NaOH to adjust the pH value between 5-6; after the reaction, filter water and alcohol, wash each for several times, dry in vacuum at 60°C, and store in a desiccator. SEM taken with a JSM-5900 scanning electron microscope such as figure 1 As shown, oblong particles with submic...

Embodiment 2

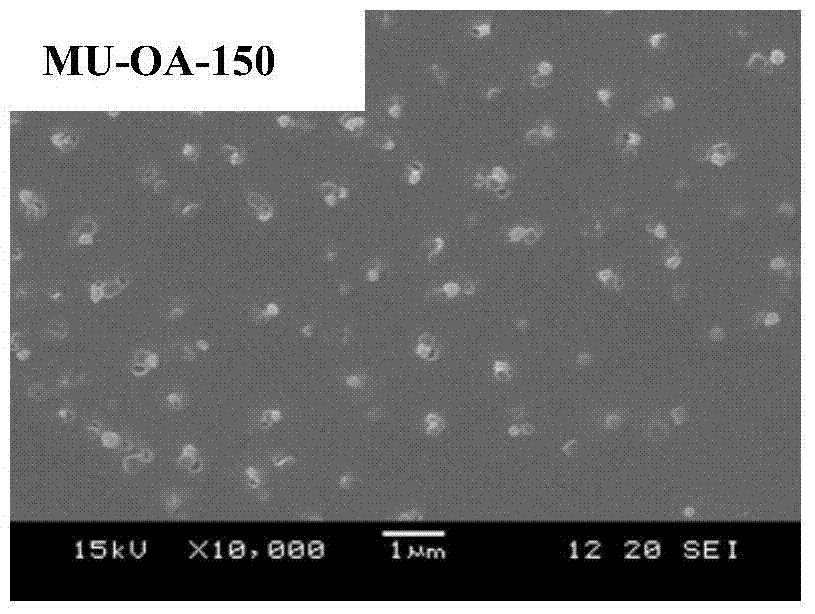

[0031] Preparation of Sm by Microwave Ultrasonic Method 0.5 Yb 0.5 (TTA) 3 Phen (MU-OA-150) light-converting nanomaterials, weighing 6mmol samarium chloride (SmCl 3 ·6H 2 O)+3mmol ytterbium chloride (YbCl 3 ·6H 2 O) 40ml ethanol solution, 6mmol1,10-phenanthroline (Phen) 30ml ethanol solution, 18mmol α-thienoyl trifluoroacetone (HTTA) 70ml ethanol solution, 6mmol oleic acid (OA) 35ml ethanol solution, in microwave ultrasonic First add HTTA solution into the four-port flat-bottomed glass reaction vessel of the combined reactor (microwave power 500W, ultrasonic power 800W, reaction temperature 60°C, reaction time 60min), and then use a peristaltic pump to sequentially add SmCl 3 ·6H 2 O+YbCl 3 ·6H 2 O solution, Phen solution, and finally OA solution were introduced, and 1mol / L NaOH was used to adjust the pH value between 5-6; after the reaction was completed, the water and alcohol were filtered and washed several times, dried in vacuum at 60°C, and stored in a desiccator....

Embodiment 3

[0033] Up and down bidirectional light conversion complex powder Sm 0.5 Yb 0.5 (TTA) 3 Compounding of Phen with EVA granules (EST-0.2), using Sm with up and down bidirectional light conversion complexes 0.5 Yb 0.5 (TTA) 3 Compound 0.02g of Phen powder with 10g of EVA: use 200mlTHF to completely dissolve 10g of EVA particles at room temperature (25°C) in advance, and then add Sm, which is fully ultrasonically dispersed with isopropanol 500W / 30min 0.5 Yb 0.5 (TTA) 3 Phen powder particles and 0.1g cross-linking agent BPO are stirred with a magnetic stirrer at 2400r / min, and dried at 40°C for 2 hours to form a film; then use a flat vulcanizer to press the film: temperature 145°C, pressure 10MPa, holding time 10min.

[0034] The contrast curve of transmittance between EVA film material with up and down two-way light conversion function and EVA pure sample is as follows: Figure 5 As shown, the up and down bidirectional light conversion organic powder Sm 0.5 Yb 0.5 (TTA) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com