Functional nutrition fertilizer and preparation method thereof

A nutrient fertilizer and functional technology, applied in the field of functional nutrient fertilizer and its preparation, can solve the problems of imbalance of trace elements, unfavorable human health, increase of inorganic matter content, etc. The effect of improving the soil environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

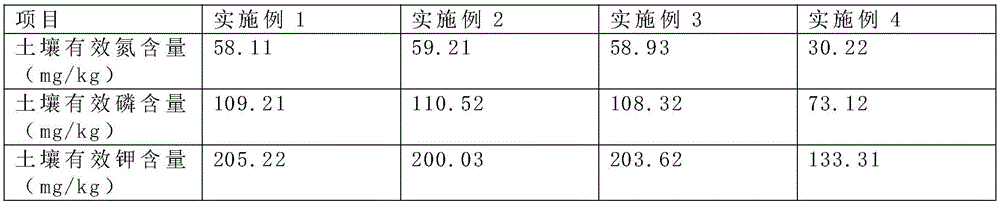

Examples

Embodiment 1

[0036] Take 10 parts by weight of EM bacterial agent and add it to 200 parts of rice washing water at 35°C, stir evenly to obtain a mixed bacterial solution for later use; take the following raw materials in parts by weight: 200 parts of organic waste, 60 parts of peat, 60 parts of poultry manure, seaweed Mix 50 parts of mud, add to the mixed bacterial solution obtained above, stir evenly, compost and ferment at 35°C for 10 days, when the temperature of the material reaches above 45°C, turn the pile, cool down and ventilate the material.

[0037] Take the following raw materials in parts by weight: 2 parts of magnesium sulfate, 3 parts of potassium chloride, 2 parts of calcium carbonate, 3 parts of bentonite, 5 parts of urea, and 50 parts of Chinese medicine extract, mix them, add them to the fermentation material obtained above and mix evenly, after mixing The fermented material and the EM microbial agent are inoculated with the EM microbial agent in the mixed fermented materi...

Embodiment 2

[0044] Take 50 parts by weight of EM bacterial agent and add it to 600 parts of rice-washing water at 35°C, stir evenly to obtain a mixed bacterial solution for later use; take the following raw materials in parts by weight: 500 parts of organic waste, 20 parts of peat, 120 parts of poultry manure, seaweed Mix 100 parts of mud, add to the mixed bacterial solution obtained above, stir evenly, compost and ferment at 35°C for 10 days, when the temperature of the material reaches above 45°C, turn the pile, cool down and ventilate the material.

[0045] Take the following raw materials in parts by weight: 6 parts of magnesium sulfate, 8 parts of potassium chloride, 8 parts of calcium carbonate, 10 parts of bentonite, 10 parts of urea, and 10 parts of Chinese medicine extract are mixed, added to the fermentation material obtained above and mixed evenly, after mixing The fermented material and the EM microbial agent are inoculated with the EM microbial agent in the mixed fermented mat...

Embodiment 3

[0052] Take 30 parts by weight of EM bacterial agent and add it to 400 parts of rice washing water at 35°C, stir evenly to obtain a mixed bacterial solution for later use; take the following raw materials in parts by weight: 300 parts of organic waste, 40 parts of peat, 100 parts of poultry manure, seaweed Mix 80 parts of mud, add to the mixed bacterial solution obtained above, stir evenly, compost and ferment for 10 days at 35°C, control the moisture content of the material at 55% to 65%, and turn the compost when the temperature of the material reaches above 45°C. Cool and aerate the material.

[0053] Take the following raw materials in parts by weight: 4 parts of magnesium sulfate, 5 parts of potassium chloride, 6 parts of calcium carbonate, 6 parts of bentonite, 8 parts of urea, and 30 parts of Chinese medicine extract, mix them, add them to the fermentation material obtained above and mix evenly, after mixing The fermented material and the EM microbial agent are inoculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com