Medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and production technological method thereof

A technology of non-quenched and tempered steel and production process, applied in the fields of non-quenched and tempered steel and its production process, medium carbon non-quenched and tempered steel and its production process, can solve the problem of unsatisfactory performance of free-cutting non-quenched and tempered steel and easy casting billet. Slag sticking and cracking, unable to meet the material machinability requirements of the manufacturing industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

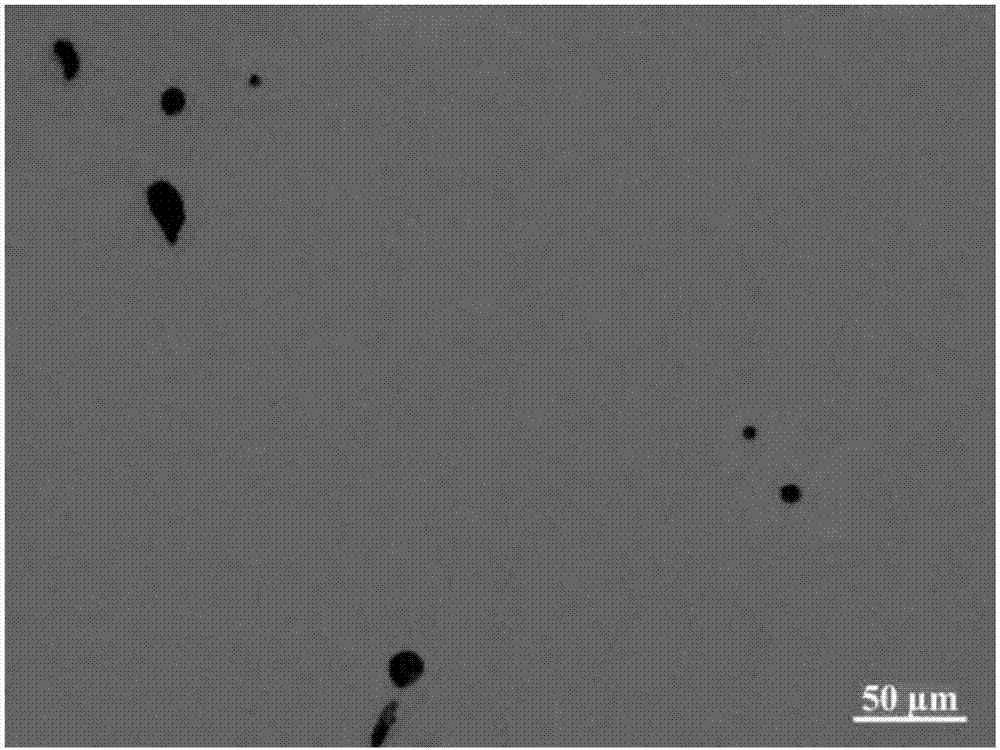

Examples

Embodiment 1

[0050] In this embodiment, a medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium has the main element composition and element weight percentage (wt%) as shown in the following table:

[0051] Table 1. Chemical composition control table of medium carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium in Example 1 (weight, %)

[0052] Element

C

Si

mn

P

S

Te

Mo

Nb

V

N

Ca

content / %

0.38

0.58

1.42

0.01

0.002

0.05

0.04

0.015

0.10

0.015

0.0015

[0053]In this example, the medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium except the main elements in Table 1, the rest is iron and unavoidable impurities, wherein the weight ratio of tellurium / sulfur is 2.5:1.

[0054] The production process method of medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium...

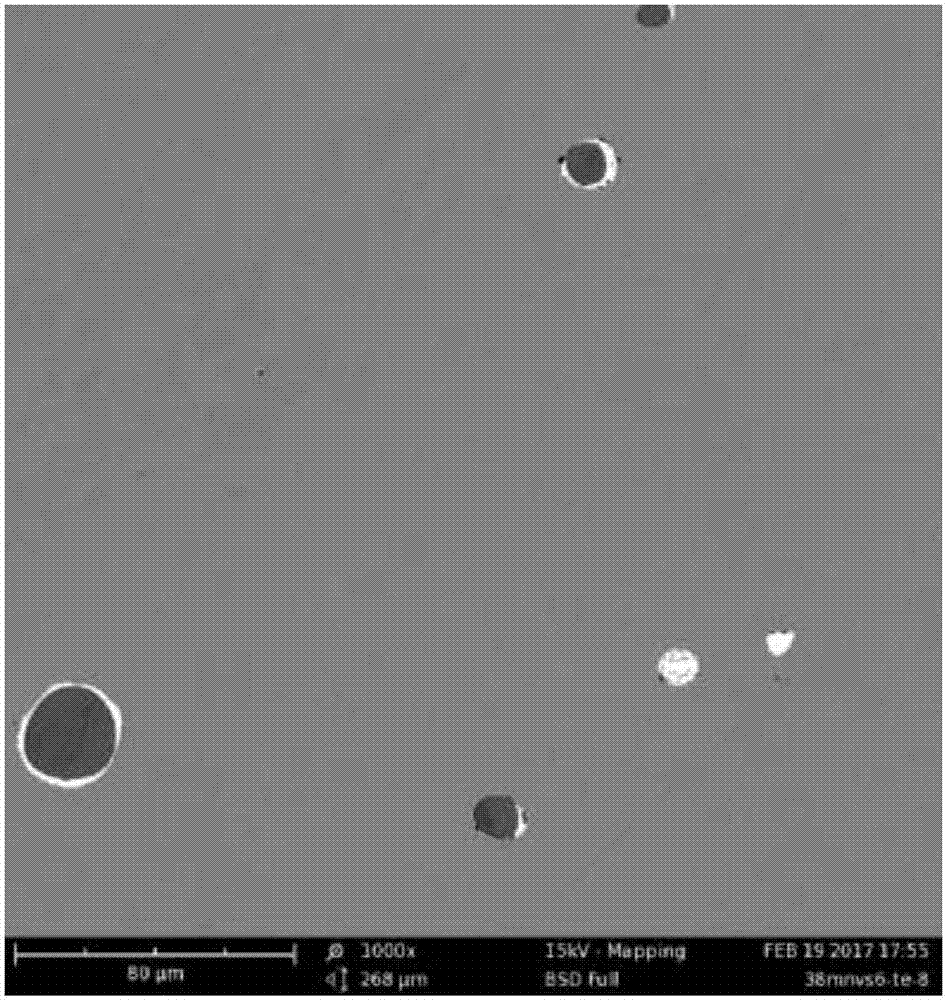

Embodiment 2

[0076] This embodiment is basically the same as Embodiment 1, especially in that:

[0077] In this embodiment, a medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium has the main element composition and element weight percentage (wt%) as shown in the following table:

[0078] Table 3. Chemical composition control table of medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium in Example 2 (weight, %)

[0079] Element

C

Si

mn

P

S

Te

Mo

Nb

V

N

Ca

content / %

0.49

0.64

1.38

0.02

0.06

0.03

0.02

0.018

0.08

0.014

0.002

[0080] In this example, the medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium, in addition to the main elements in Table 3, the balance is iron and unavoidable impurities, wherein the weight ratio of tellurium / sulfur is 0.5:1.

[0081] The production process meth...

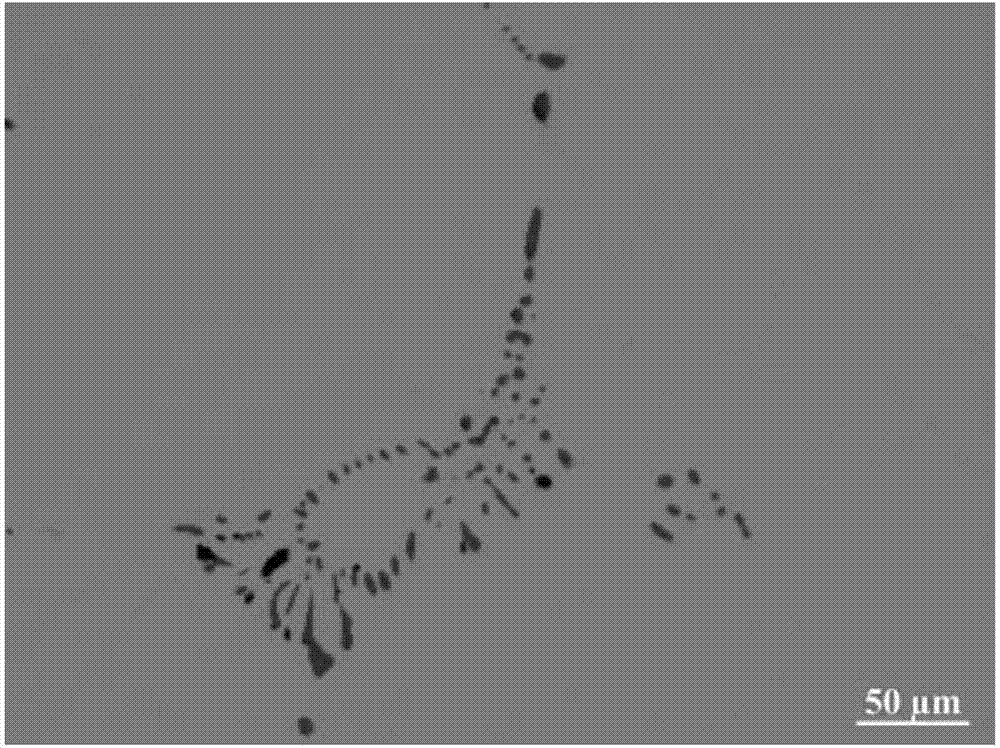

Embodiment 3

[0089] This embodiment is basically the same as the previous embodiment, and the special features are:

[0090] In this embodiment, a medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium has the main element composition and element weight percentage (wt%) as shown in the following table:

[0091] Table 4. Chemical composition control table of medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium in Example 3 (weight, %)

[0092] Element

C

Si

mn

P

S

Te

V

N

Ca

content / %

0.35

0.10

0.75

0.03

0.02

0.02

0.02

0.012

0.001

[0093] In this example, the medium-carbon free-cutting non-quenched and tempered steel containing sulfur and tellurium except the main elements in Table 4, the rest is iron and unavoidable impurities, wherein the weight ratio of tellurium / sulfur is 1:1.

[0094] The production process of medium-carbon free-cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com