Propane dehydrogenation to propylene catalyst and preparation and applications thereof

A propane dehydrogenation and catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Cumbersome and other problems, to achieve the effect of easy large-scale production, low cost of raw materials, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

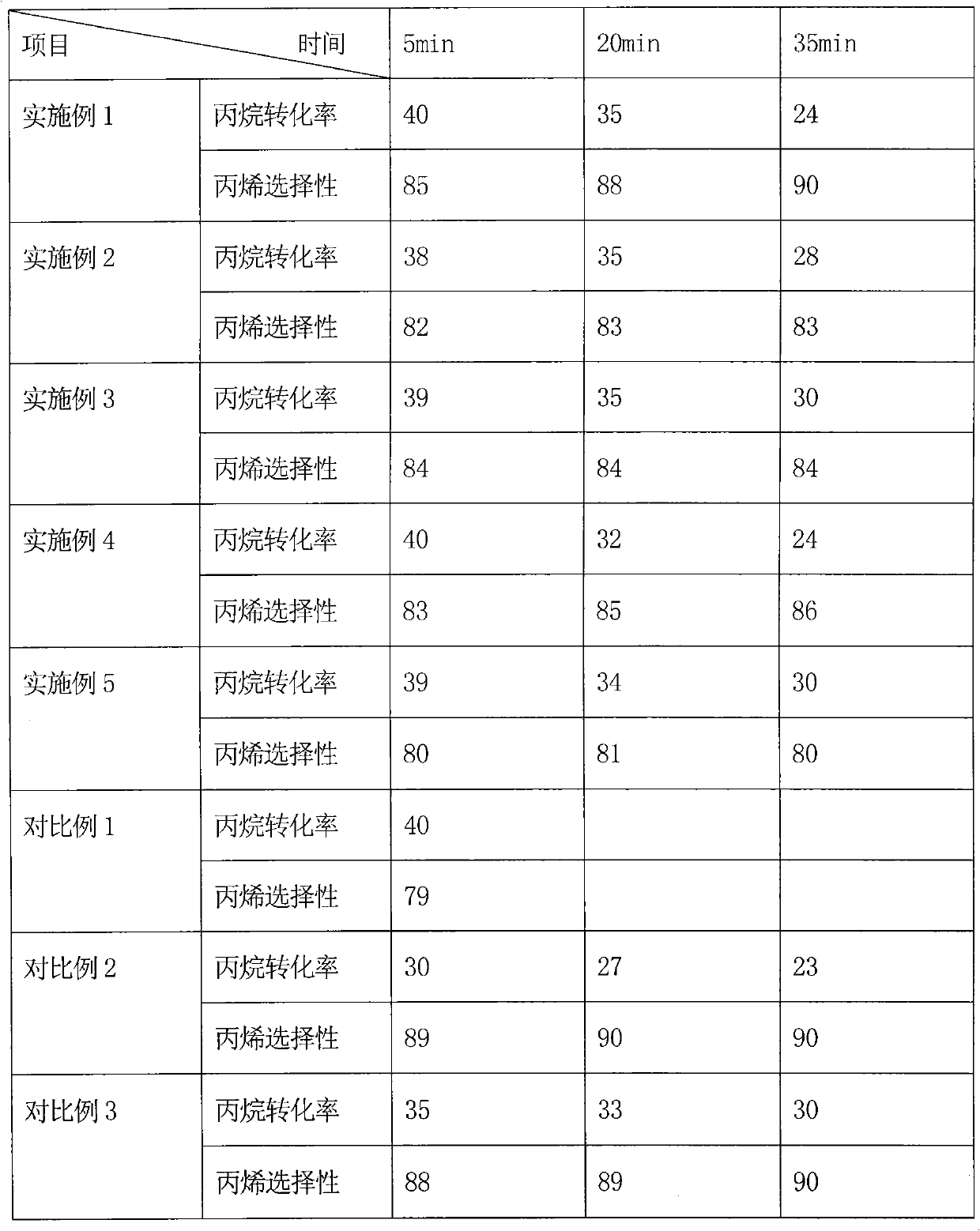

Examples

Embodiment 1

[0025] Add 66 grams of pseudo-boehmite to 250 ml of water, stir for 2 hours to form a paste, add 17.08 grams of chromium nitrate and stir for 1 hour, then add 1.74 grams of lanthanum nitrate and stir for one hour, adjust the pH value to 3 with concentrated hydrochloric acid, and continue stirring for 2 hours After aging for 2 hours, dry at 120°C for 10 hours. Rapidly raise the temperature to 550° C. under a nitrogen atmosphere and maintain it for 5 hours, and the linear velocity of nitrogen is 100 cm / min. Then switch nitrogen to air, continue to heat up to 700°C and keep it for 1 hour, then cool down naturally. The specific surface area of the catalytic catalyst screened at 40-80 mesh is 146m 2 / g, apparent bulk density 1.0.

Embodiment 2

[0027] Add 66 grams of pseudo-boehmite to 250 ml of water, stir for 2 hours to form a paste, add 8.08 grams of chromium nitrate and stir for 1 hour, then add 1.74 grams of lanthanum nitrate and stir for one hour, adjust the pH value to 3 with concentrated hydrochloric acid, and continue stirring for 2 hours After aging for 2 hours, dry at 120°C for 10 hours. Rapidly raise the temperature to 550° C. under a nitrogen atmosphere and maintain it for 5 hours, and the linear velocity of nitrogen is 100 cm / min. Then switch nitrogen to air, continue to heat up to 700°C and keep it for 1 hour, then cool down naturally. The specific surface area of the catalytic catalyst screened at 40-80 mesh is 144m 2 / g, apparent bulk density 1.0.

Embodiment 3

[0029] Add 66 grams of pseudo-boehmite with 250ml of water, stir for 2 hours to form a paste, add 17.08 grams of chromium nitrate and stir for 1 hour, then add 1.74 grams of lanthanum nitrate and 0.1 grams of potassium nitrate and stir for one hour, adjust the pH value to 3. Continue to stir for 2 hours, age for 2 hours, and dry at 120°C for 10 hours. Rapidly raise the temperature to 550° C. under a nitrogen atmosphere and maintain it for 5 hours, and the linear velocity of nitrogen is 100 cm / min. Then switch nitrogen to air, continue to heat up to 700°C and keep it for 1 hour, then cool down naturally. The specific surface area of the catalytic catalyst screened at 40-80 mesh is 144m 2 / g, apparent bulk density 1.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com