Ultra-thick type polyimide film and preparation method thereof, and graphite sheet

A polyimide film, ultra-thick technology, applied in the field of polyimide, can solve the problems of reducing resin leveling, affecting quality stability, high apparent resin viscosity, etc., reducing the requirements for catalytic activity, Improve the regularity of molecular structure and avoid the effect of high surface viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

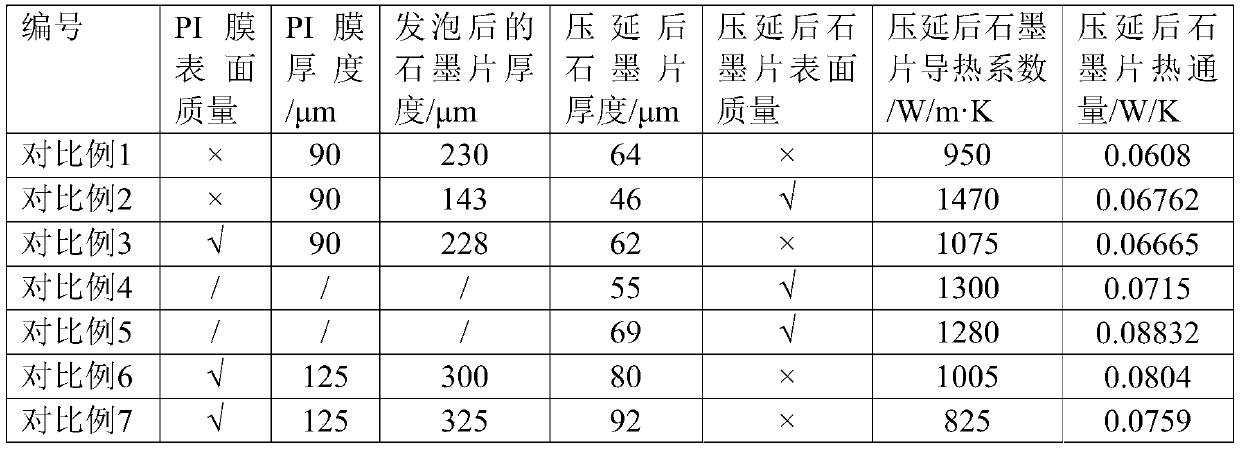

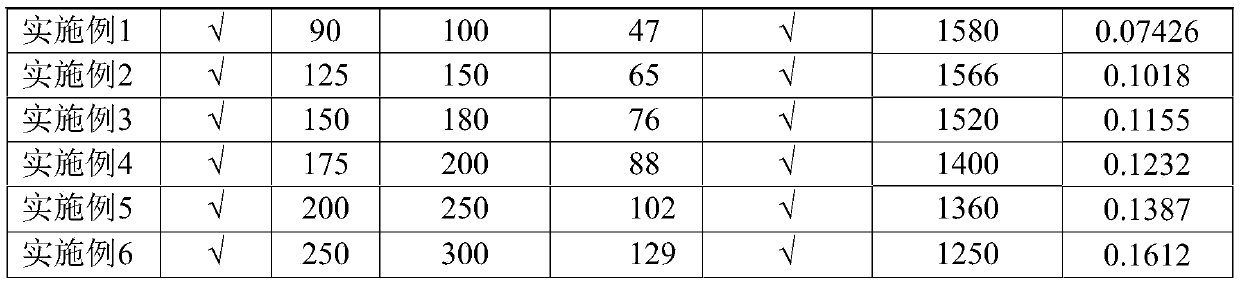

Embodiment 1

[0059] A preparation method of graphite sheet of the present invention, comprising:

[0060] (1) Resin preparation: 0.88 kg of carboxylated modified CNTs with a diameter of 100 nm and a length of 0.6 μm and 0.19 kg of Ca 2 P 2 o 7 Dissolve in 486.05kg of DMF, stir evenly, add 21.6kg of 1,4-PDA and 15.6kg of BAPP, after the diamine is dissolved, add 43.6kg of PMDA and 11.78kg of 4,4-ODPA in batches, Finally, 5.2 kg of 4-PEPA was added for capping, and when the viscosity of the resin reached 1920 poise, it was defoamed and stored at 4°C for use (solid content was about 17%);

[0061] (2) Preparation of PI film: Mix the resin prepared in step (1) with 163.44kg propionic anhydride and 1.75kg pyridine evenly, then flow through a gradient temperature rise of 120-190°C to form a film, and then imidize at a high temperature of 225-440°C, and finally 310 ℃ annealing and heat setting treatment to prepare a polyimide film with a thickness of 90 μm;

[0062] (3) Graphite sheet prepara...

Embodiment 2

[0064] A preparation method of graphite sheet of the present invention, comprising:

[0065] (1) Resin preparation: first, 0.25 kg of amination-modified CNTs with a diameter of 15 nm and a length of 15 μm and 0.52 kg of SiO with a particle size of 4 μm 2 Dissolve in 313.2kg of NMP, stir well and add 43.2kg of 4,4'-ODA, after the diamine is dissolved, add 54.4kg of PMDA in batches, then add 6.8kg of 3,4'-ODA to continue the reaction , and finally add 2.92kg of EPA for capping, when the viscosity of the resin reaches 1820 poise, defoam and store at 12°C for later use;

[0066] (2) Preparation of PI film: Mix the resin prepared in step (1) with 116.52kg of acetic anhydride and 4kg of pyridine evenly, then flow through a gradient temperature rise of 105-185°C to form a film, imidize at a high temperature of 230-435°C, and finally 340°C Annealing and heat setting to prepare a polyimide film with a thickness of 125 μm;

[0067] (3) Graphite sheet preparation: the polyimide film is...

Embodiment 3

[0069] A preparation method of graphite sheet of the present invention, comprising:

[0070] (1) Resin preparation: 0.23 kg of carboxylated modified CNTs with a diameter of 150 nm and a length of 2 μm and 0.94 kg of CaHPO with a particle size of 4.2 μm 4 Dissolve in 369.3kg of DMAc, stir well, add 36.2kg of 4,4'-ODA, 5.8kg of PDA, after the diamine is dissolved, add 57.11kg of PMDA in batches, and then add 11.2kg of BAPP to adjust the viscosity , and finally add 0.96kg of 4PEPA to end capping, when the viscosity of the resin reaches 1950 poise, defoam and store at 2°C for later use;

[0071] (2) Preparation of PI film: Mix the resin prepared in step (1) with 57.55kg of benzoic anhydride and 2.55kg of imidazole evenly, and then saliva film-forming by gradient heating at 110-175°C, high-temperature imidization at 235-415°C, and finally Annealing heat setting at 300°C to prepare a polyimide film with a thickness of 150 μm;

[0072] (3) Preparation of graphite sheet: Put the PI ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com