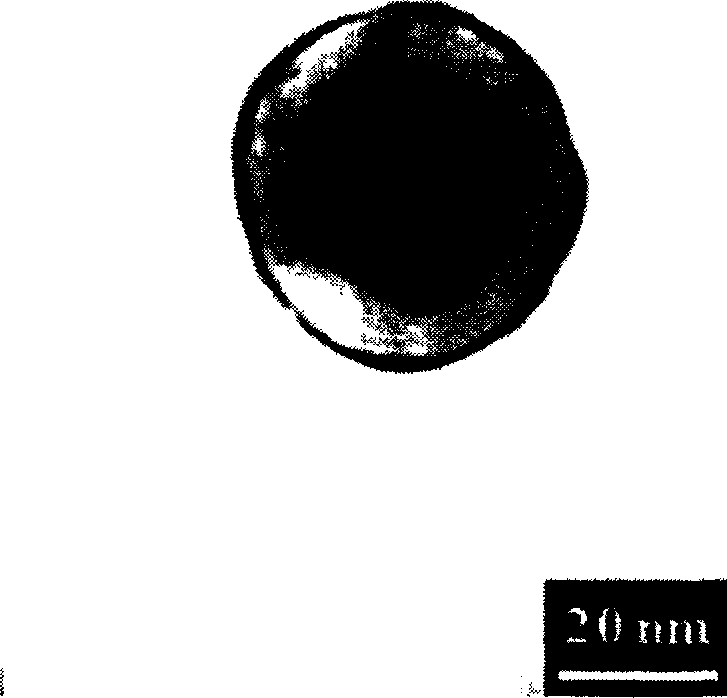

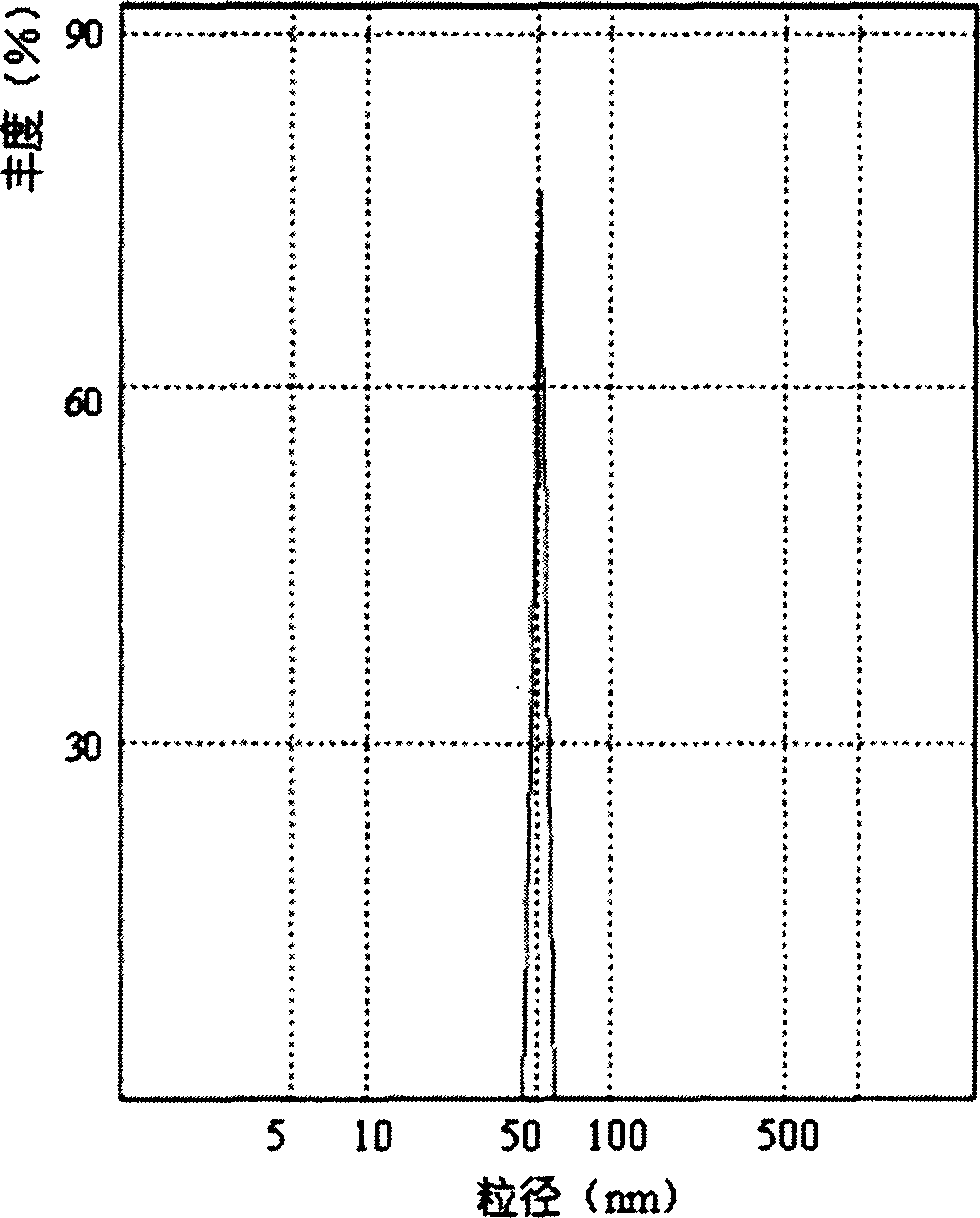

Nano macromolecule microball of carboxy function type cross-linked nucleocapsid structure and preparation process thereof

A nano-polymer, core-shell structure technology, applied in the field of nano-polymer microspheres and its preparation, can solve the problems of poor solvent resistance and oil absorption, achieve the effect of enhancing interface compatibility, broadening application fields and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: 70 parts of styrene (St) as the core layer monoolefin monomer and 7 parts of divinylbenzene (DVB) as the core layer polyolefin monomer were mixed uniformly and set aside. Add 360 parts of deionized water, 6.5 parts of sodium dodecylsulfonate (SDS) and 0.5 part of nonylphenol polyoxyethylene ether into a four-necked bottle equipped with mechanical stirring, reflux condenser and thermometer, and raise the temperature to 50°C , add 30% of the previously prepared mixture to form a uniform emulsion. Then add 80% of the initiator aqueous solution made up of 0.5 parts of water-soluble initiator ammonium persulfate and 72 parts of deionized water, and raise the temperature to 82° C. for 30 minutes. Then the rest of the previously prepared mixture was added to the system, and the reaction was continued for 1 hour. Then add all the remaining initiator solution, and add 30 parts of butyl acrylate (BA) (as the shell monoolefin monomer) and 3 parts of divinylbenzene (DVB...

Embodiment 2

[0061] Example 2: 30 parts of butyl acrylate (BA) as the core layer monoolefin monomer and 3 parts of trimethylolpropane trimethacrylate (TM) as the core layer polyolefin monomer were mixed uniformly and set aside. Add 360 parts of deionized water, 4 parts of sodium dodecylsulfonate (SDS) and 0.5 part of nonylphenol polyoxyethylene ether into a four-necked bottle equipped with mechanical stirring, reflux condenser and thermometer, and raise the temperature to 50°C , add 70% of the previously prepared mixture to form a uniform emulsion. Then add 20% of the initiator aqueous solution made up of 0.5 parts of water-soluble initiator ammonium persulfate and 72 parts of deionized water, and raise the temperature to 70° C. for 2 hours. Then the temperature was raised to 82° C., and the rest of the previously prepared mixture was added to the system, and the reaction was continued for 1 hour. Then add all the remaining initiator solution, and add 70 parts of methyl methacrylate (MMA)...

Embodiment 3

[0062] Embodiment 3: Change methacrylic acid into 40 parts of oleic acid in Example 1, change the amount of sodium bicarbonate into 20 parts, increase the amount of initiator to 2 parts simultaneously, and the system temperature is 70 ℃, and the reaction time under each step Be respectively 2 hours, 3 hours, 3 hours, 3 hours, all the other formulas and steps are identical with embodiment 1. The performance index of the obtained product is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com