Graphite negative electrode material for lithium ion battery and preparation method of graphite negative electrode material

A lithium-ion battery and graphite negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited application of graphite negative electrode materials, and the improvement of high-current charge and discharge performance is not very significant, so as to reduce the irreversible capacity , Improve electrochemical performance, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

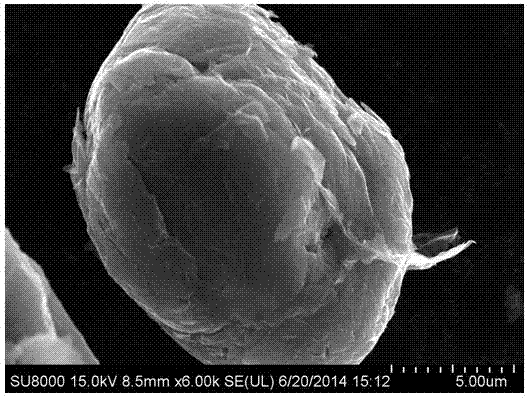

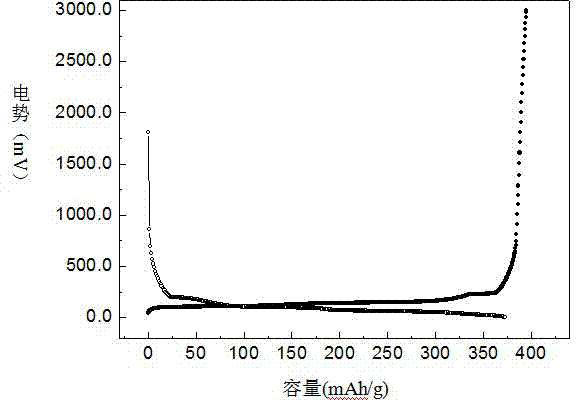

[0032] A kind of graphite negative electrode material for lithium ion battery of the present invention, this graphite negative electrode material is to be core with graphite material, is coated with a conductive network film that one deck is made up of lignin pyrolytic carbon and graphene on the surface of graphite material; The mass of the network film is 0.3% of the mass of the graphite negative electrode material.

[0033] The preparation method of the lithium ion battery graphite negative electrode material of the present embodiment may further comprise the steps:

[0034] Dissolve 200mg lignin (any one of ammonium lignosulfonate, sodium lignosulfonate, calcium lignosulfonate and magnesium lignosulfonate) and 100mg graphene oxide (1~10 layers) in 100mL In water, ultrasonic treatment for 2h. Add 5g of graphite powder to the well-dispersed mixture of lignin and graphene oxide, continue ultrasonic stirring for 1 hour, and slowly dry at 120°C, and put the dried material into ...

Embodiment 2

[0038] A kind of graphite negative electrode material for lithium ion battery of the present invention, this graphite negative electrode material is to be core with graphite material, is coated with a conductive network film that one deck is made up of lignin pyrolytic carbon and graphene on the surface of graphite material; The mass of the network film is 0.3% of the mass of the graphite negative electrode material.

[0039] The preparation method of the lithium ion battery graphite negative electrode material of the present embodiment may further comprise the steps:

[0040] Dissolve 300mg lignin (one or more of ammonium lignosulfonate, sodium lignosulfonate, calcium lignosulfonate and magnesium lignosulfonate) and 100mg graphene oxide (less than 3 layers) in 200mL ethanol , ultrasonic sonication for 2h. Add 5g of graphite powder to the well-dispersed mixture of lignin and graphene oxide, continue ultrasonic stirring for 1 hour, and slowly dry at 120°C, and put the dried ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com