Preparation method of polyaniline modified multi-wall carbon canotube/epoxy resin composite material

A technology of multi-walled carbon nanotubes and epoxy resin, which is applied in the treatment of fibrous fillers and dyed polymer organic compounds, etc., to achieve the effect of improving mechanical properties and strong interfacial interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

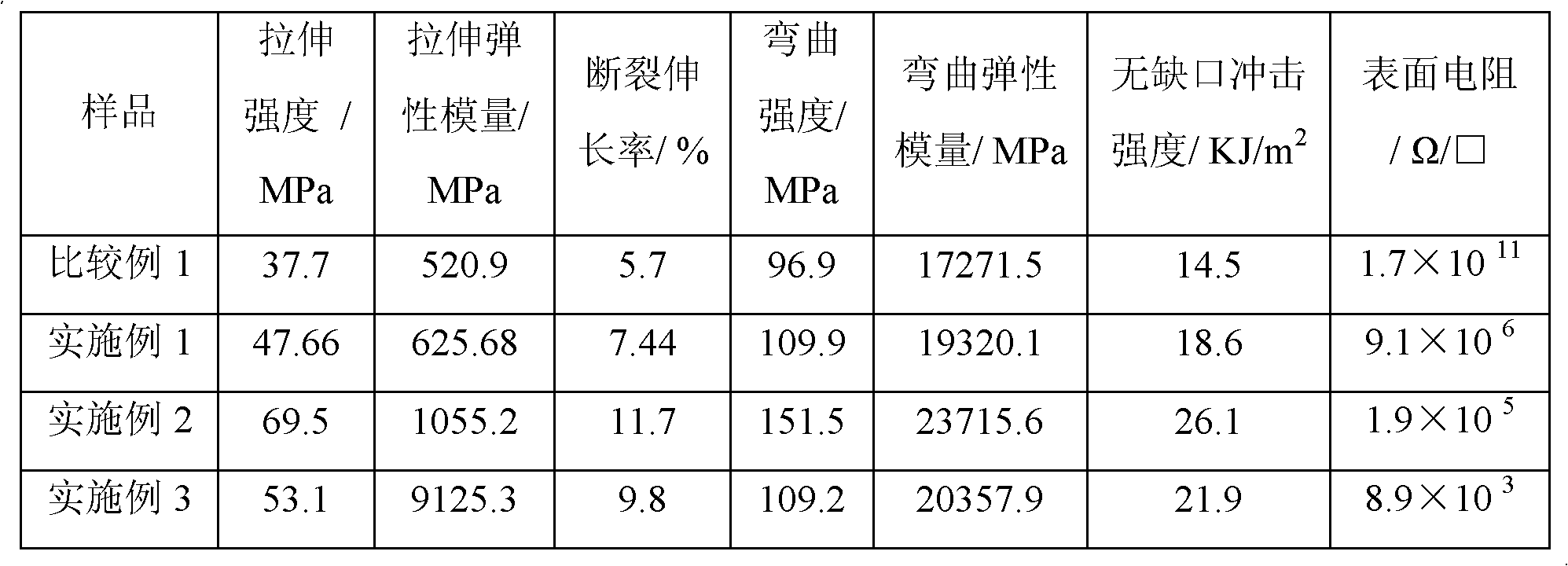

Examples

Embodiment 1

[0019] (1) 0.2g dry surface with carboxyl multi-walled carbon nanotubes is added to 200ml (0.04mol / l) dodecylbenzenesulfonic acid solution, ultrasonically stirred for 0.5 hour; then 1 g (0.01mol) aniline is added dropwise in the above-mentioned suspension of multi-walled carbon nanotubes, the time for dropping is 1 hour, and then ultrasonically stirred for 1 hour; then 50ml (0.2mol / l) ammonium persulfate aqueous solution is added dropwise in the above-mentioned reaction system , the dropping time is 0.5 hours, and then continue to react for 2 hours until the end of the reaction. The above-mentioned whole polymerization reaction process is always carried out at a temperature of 35°C and under ultrasonic stirring, and then it is demulsified by acetone, washed with deionized water, and filtered by a microporous membrane. and drying to obtain polyaniline modified multi-walled carbon nanotubes;

[0020] (2) Add 1 g of the above-mentioned polyaniline-modified multi-walled carbon nan...

Embodiment 2

[0024] (1) Add 0.2g of dry multi-walled carbon nanotubes with carboxyl groups on the surface to 200ml (0.05mol / l) camphorsulfonic acid solution, and ultrasonically stir for 0.5 hours; then add 1g (0.01mol) aniline dropwise to the above-mentioned multi-walled carbon nanotubes In the carbon nanotube suspension, the dropping time is 1 hour, and then ultrasonically stirred for 1 hour; then 50ml (0.2mol / l) ammonium persulfate aqueous solution is added dropwise to the above reaction system, the dropping time is 0.5 hour, and then continue After reacting for 3 hours to the end of the reaction, the above-mentioned entire polymerization process is always carried out at a temperature of 35°C and under ultrasonic stirring, and then demulsified with acetone, washed with deionized water, filtered with a microporous membrane and dried to obtain a polyaniline modified polymer. Walled carbon nanotubes;

[0025](2) Add 5 g of the polyaniline-modified multi-walled carbon nanotubes to 50 ml of a...

Embodiment 3

[0027] (1) Add 0.2g of dry multi-walled carbon nanotubes with carboxyl groups on the surface to 200ml (0.05mol / l) p-toluenesulfonic acid solution, and ultrasonically stir for 0.5 hours; then add 1g (0.01mol) aniline dropwise In the above multi-walled carbon nanotube suspension, the dropping time is 1 hour, and then ultrasonically stirred for 1 hour; then 50ml (0.2mol / l) ammonium persulfate aqueous solution is added dropwise to the above reaction system, and the dropping time is 0.5 hour , and then continue to react for 4 hours until the end of the reaction. The above-mentioned whole polymerization process is always carried out at a temperature of 35°C and under ultrasonic stirring, and then filtered through a microporous membrane, washed with deionized water and dried to obtain polyaniline modified multi-wall carbon nanotubes;

[0028] (2) Add 10 g of the above-mentioned polyaniline-modified multi-walled carbon nanotubes into 50 ml of tetrahydrofuran, stir ultrasonically for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com