Medical puncture-proof glove with warp knitting three-dimensional structure

A three-dimensional structure and glove technology, applied in gloves, warp knitting, application, etc., can solve the problems of softness and other problems, and achieve the effect of improving the anti-stab effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

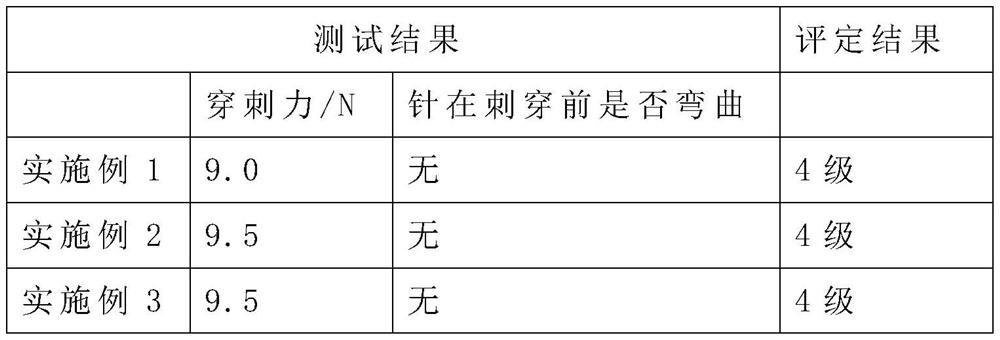

Embodiment 1

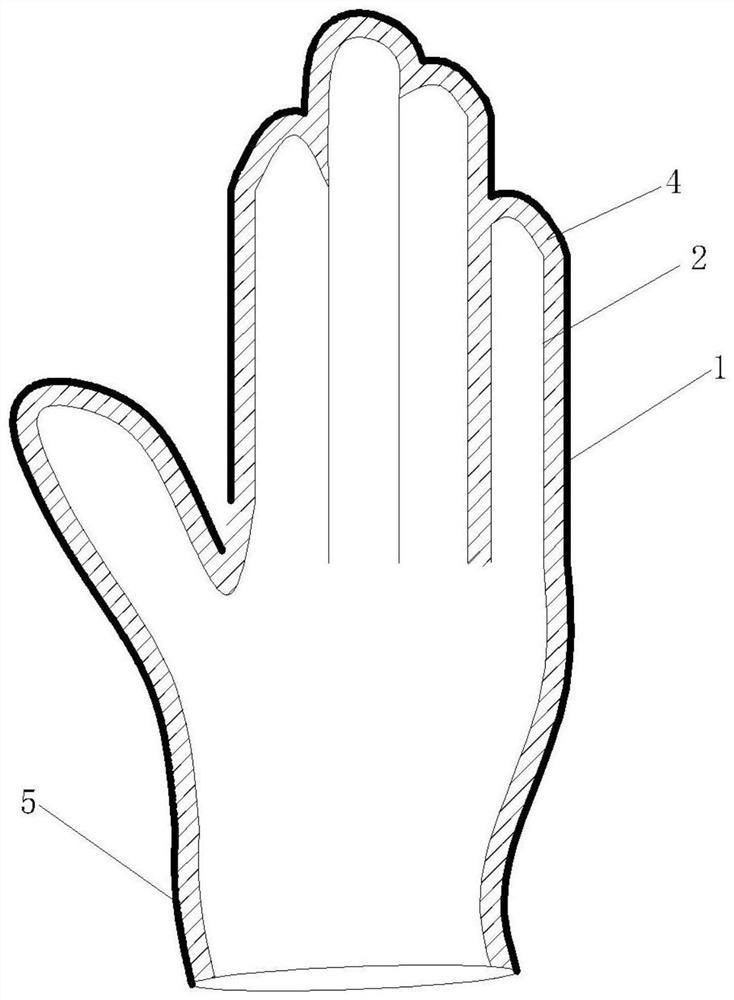

[0024] Such as figure 1 As shown, the medical stab-resistant glove of warp-knitted three-dimensional structure described in this embodiment is made by the following steps:

[0025] (1) Weave two warp-knitted three-dimensional structure fabrics in the shape of a hand, one as the palm side of the glove body, and the other as the back side of the palm body; sew the two pieces of fabric into the glove body; specifically:

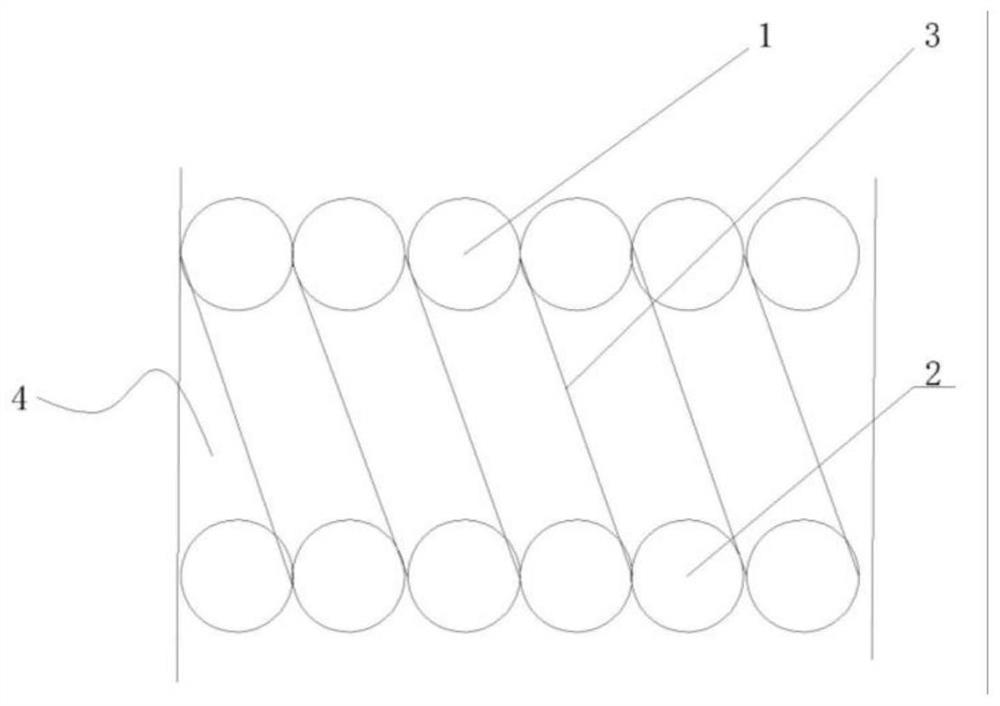

[0026] The warp-knitted three-dimensional structure fabric includes an upper surface layer 1, a lower surface layer 2 and a connecting thread 3 connecting the upper surface layer 1 and the lower surface layer 2, and the upper surface layer 1 and the lower surface layer 2 of the fabric are nested together by several strings formed by warp knitting. Composed of coils; the coils nested in series are connected by a plurality of connecting wires 3 to form an intermediate buffer layer 4 with stab-proof buffering effect; the fibers of the upper surface layer 1 and the ...

Embodiment 2

[0035] Such as figure 1 As shown, the medical stab-resistant glove of warp-knitted three-dimensional structure described in this embodiment is made by the following steps:

[0036] (1) Weave two warp-knitted three-dimensional structure fabrics in the shape of a hand, one as the palm side of the glove body, and the other as the back side of the palm body; sew the two pieces of fabric into the glove body; specifically:

[0037] The warp-knitted three-dimensional structure fabric includes an upper surface layer 1, a lower surface layer 2 and a connecting thread 3 connecting the upper surface layer 1 and the lower surface layer 2, and the upper surface layer 1 and the lower surface layer 2 of the fabric are nested together by several strings formed by warp knitting. Composed of coils; the coils nested in series are connected by a plurality of connecting wires 3 to form an intermediate buffer layer 4 with stab-proof buffering effect; the fibers of the upper surface layer 1 and the ...

Embodiment 3

[0045] Such as figure 1 As shown, the medical stab-resistant glove of warp-knitted three-dimensional structure described in this embodiment is made by the following steps:

[0046] (1) Weave two warp-knitted three-dimensional structure fabrics in the shape of a hand, one as the palm side of the glove body, and the other as the back side of the palm body; sew the two pieces of fabric into the glove body; specifically:

[0047]The warp-knitted three-dimensional structure fabric includes an upper surface layer 1, a lower surface layer 2 and a connecting thread 3 connecting the upper surface layer 1 and the lower surface layer 2, and the upper surface layer 1 and the lower surface layer 2 of the fabric are nested together by several strings formed by warp knitting. Composed of coils; the coils nested in series are connected by a plurality of connecting wires 3 to form an intermediate buffer layer 4 with stab-proof buffering effect; the fibers of the upper surface layer 1 and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com